Jiangyin Dingbo Technology CO., Ltd. |

|

Metal Roof Ridge Cap Roll Forming Machinery in Wall Board for Attached Part Product

Introduction:

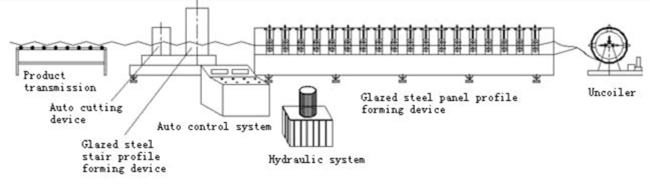

The cap ridge roll forming machine is to produce angel title saving human resources and lower labor cost. This equipment is made up of automatic discharge table, feed leading table, and main forming machine, cutting device, hydraulic station and computer control system. Especially, the Optional system is normal uncoiler and hydraulic uncoiler.

This product is widely used in many kinds of industrial factory, civilian buildings, and wall board for attached part product. It has advantage of pretty appearance, durable using and so on. It is producted continuously as roll forming machine instead using bending machine to make angel tile saving human resources, lower labor cost.

The roof ridge cap roll forming machine can form metal ridge which is mostly used with colorful roofing tile sheets. After roll formed by this machine, the surface will be smooth and beautiful without any scratch on surface.

The main detail specification as follows:

| Material thickness | 0.4-0.8mm |

| Working speed | 12-30m/min |

| Roll station | 10 stations |

| Main power | 5.5KW |

| Hydraulic power | 3KW |

| Control system | PLC Panasonic |

| Drive | by chain |

Advantage:

1. We use Automatic control software to manage productive information.

2. Thanks to the High integrated network, the whole automatic control system has an improvement in automaticity.

3. High performance in operation, maintenance, and debugging. Easy to load and unload.

4. First in quality

5. First in time

6. First in price

7. First in services

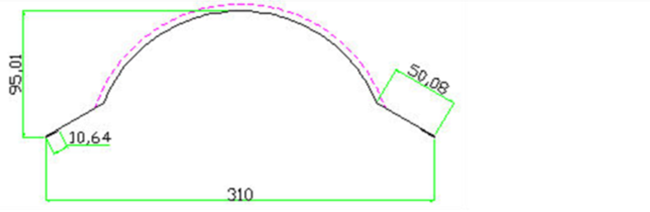

The profile drawing:

Working flow: