BEIJING SINO STEEL ENGINEERING & EQUIPMENT CO., LTD. |

|

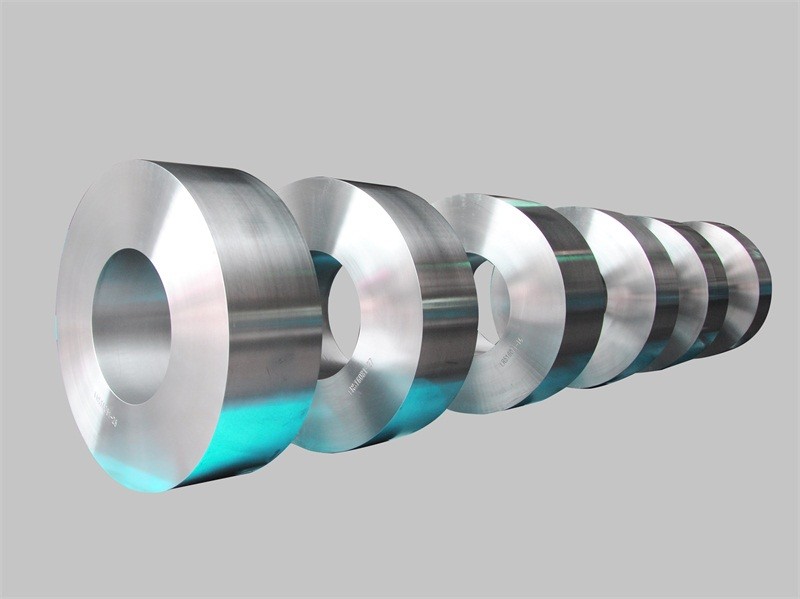

Tungsten Carbide Roll Rings hard alloy ring cemented carbide rolling ring

1.Size: Usually according to customers' requirements or drawings.

2. Tolerance:Usually according to customers or we supply reasonable tolerance.

3.Surface finish: Standard value 3.2-0.1 or mirror polishing if required.

4.Material grade:Cobalt,nickel base such as YG8,YN6,etc.

5.Products requirements:Guarantee the concentricity and coaxiality.

Advantage:

1.Carbide Seals made by excellent wear corrosion resistance,low friction coefficient,good toughness material so have long using life.

2. most excellent seal face material in the seal material world.

One of main reasons for using Tungsten Carbide is the additional wear resistance that can be achieved in both moving and static parts.This is particular the case in serve service conditions, such as high temperature,and high levels of corrosion and abrasion.

Installation of cemented carbide roll rings

The sleeve insertion and assmbly of tungsten carbide roll rings

shall be carried out in accordance with the requirements of

precision.There shall be appropriate space between the roll rings

and axle or between the roll rings and sleeve. It is neither tight

nor loose.It should be checked whether the roll rings conforms to

the technological requirement, and clean the mounting surface of

roll rings,sleeve and axle before the installation.It is prohibited

to beat the roll rings with hammer or other hard things while

assemblying.

| Grade | Binder(Wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

| YN6 | 6 | 14.7 | 89.5 | 1460 |

| YN6X | 6 | 14.8 | 90.5 | 1400 |

| YN6A | 6 | 14.8 | 91.0 | 1480 |

| YN8 | 8 | 14.6 | 88.5 | 1710 |

Cobalt Binder Grades:

| Grade | Binder(Wt%) | Density(g/cm3) | Hardness(HRA) | TRS(≥N/mm2) |

| YG6 | 6 | 14.8 | 90 | 1520 |

| YG6X | 6 | 14.9 | 91 | 1450 |

| YG6A | 6 | 14.9 | 92 | 1540 |

| YG8 | 8 | 14.7 | 89.5 | 1750 |

| YG12 | 12 | 14.2 | 88 | 1810 |

| YG15 | 15 | 14.0 | 87 | 2050 |

| YG20 | 20 | 13.5 | 85.5 | 2450 |