BEIJING SINO STEEL ENGINEERING & EQUIPMENT CO., LTD. |

|

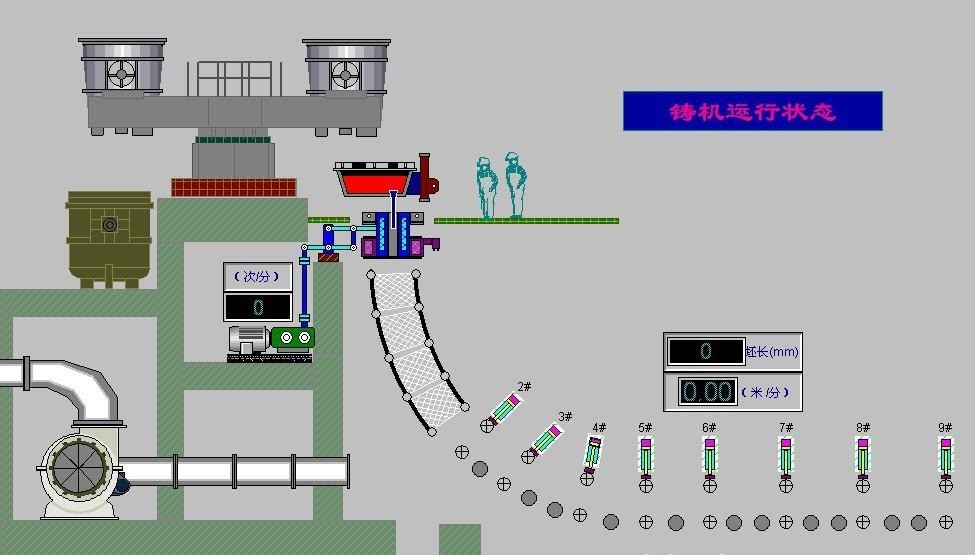

CCM Continuous Casting Machine round billet CCM for R3.5-10m steel billet

It’s one kind continuous casting steel technology major for seamless steel tube production. Its advantages are high precision billet, good quality, low energy consumption and high metal recovery rate. The development of round billet casting technology accelerates the process of seamless pipe rolling and casting direct connection. In addition to the round billet ccm’s crystallizer with round shape and the dummy bar’s dummy bar head with round shape, its overall equipment structure has no essential difference with square billet ccm. But because its product is seamless steel tube billet, its casting process is demanding, and there are certain characteristics of their equipment.

Technical features

1. Ladle support way: rotary table, ladle car

2. Tundish: full suspension type, semi- hanging type

3. Crystallizer mode: The overall copper tube type, parabola taper

4. Casting strand control: cesium source type liquid level

automatic control

5. Vibration mode: full plate spring, half leaf spring, sinusoidal

and non-sinusoidal

6. Secondary cooling mode: aerosol automatic water distribution,

7. Straightening mode: full arc five consecutive straightening

rollers, AC variable speed

8. Dummy way: Adaptive overall rigid dummy bar

9. Cutting way: Narrow efficient automatic flame cutting machines,

hydraulic shears

10. Steel moving mode : mechanical overhead structure

11. Control way: full PLC control, automatic and manual can be

quickly converted.

round billet ccm for sale

CCM Main Radius | R6m ( Continuous Straightened) |

| Strand Number | 4 |

| Strands Spacing | 1200mm |

| Section | 125x125mm |

| Cutting Length | 6~12m |

| Casting Type | Open Cast |

| Ladle loader | Ladle turret (including covering device and weighing system) |

| Tundish Capacity | 20t |

| Level in Tundish | 800mm |

| Tundish Car | Half hanging tundish car with mechanical traversing adjustment |

| Mold Type | Parabolic tube curve, narrow water gap |

| Mold Tube | Length900mm |

| EMS | None |

| AMLC | None |

| Oscillation Device | All board spring oscillation device, motor power:7.5KW |

| Secondary Cooling | All water atomizing cooling, automation water distributing |

| Withdrawal and straightening | Continuous straightening |

| Dummy Bar | Rigid-flexible dummy bar |

| Dummy Bar Storage | Friction wheels type |

| Cutting Type | Narrow gap torch cutting machine |

| Cutting size device | Mechanical ball type |

| Billet Discharge | Billet discharging roller table, billet moved machine, hydraulic walk-step cooling bed |