Xiamen METS Industry & Trade Co., Ltd |

|

Verified Suppliers

|

|

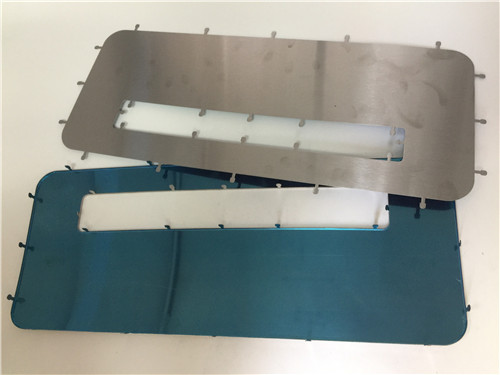

Small custom-made circuit breaker pure copper hardware stamping accessories magnetic yoke brass stamping parts

Auto spare parts,High-speed Train spare parts,Wind power

accessories,communications and security equipment spare parts,Fire

Accessories etc, such as Sheet plate series, Cabinet Series,Die

casting series, CNC machining series,Injection plastic series etc | |||

Place of Origin | Qingdao China (Mainland) | ||

Size | OEM Standard Size | ||

Color | matte or gloss or according to clent's requirement | ||

Process | Laser cutting, stamping, bending,die casting, CNC

machining,grinding,spray coating,printing,assembing etc | ||

Available Materials | AL:5052/5754/5082/5083/6061/6063/6082…. | ||

| ZL101/ZL102/ADC12… | |||

| Carbon Steel: Q235B/Q345E/Q345D/SPCC/SECC/DX51D/DX53D… | |||

| Stainless steel: 304/316/430/201... | |||

Surface | Paint spraying,Power

coating,Anodized,Polishing,Sandblasting,Electrophoresis,Passivation

etc | ||

Payment | T/T, L/C, Money Gram, Western Union | ||

Delivery | Sample: 3~5 days for no mould items and 7~10 days for mould items | ||

| Mass goods: 15~20 working days | |||

FAQ

Q: What’s your manufacture capability?

---- We use Sodick/Charmilles to frabricate die inserts,dimension

we can do is +/-0.002mm.

Q: Can you make all the dimensions are according to our

design/samples?

---- We can guarantee that all the dimensions are made according to

your drawing/sample.Please notice that dimension tolerence we can

do is +/-0.003mm.

Q: What’s your advantage compare with other supplier’s on the

market?

---- We are stamping factory,have a team contains die

design,making,maintance and stamping production.We know how

important the good mold for stamping production.So the metal

stamping parts is better that other factories.

---- All our engineers are with more than 10 years working

experience.They are more professional on precision stamping field.