High - precision metal stamping parts , metal stamping

manufacturing process

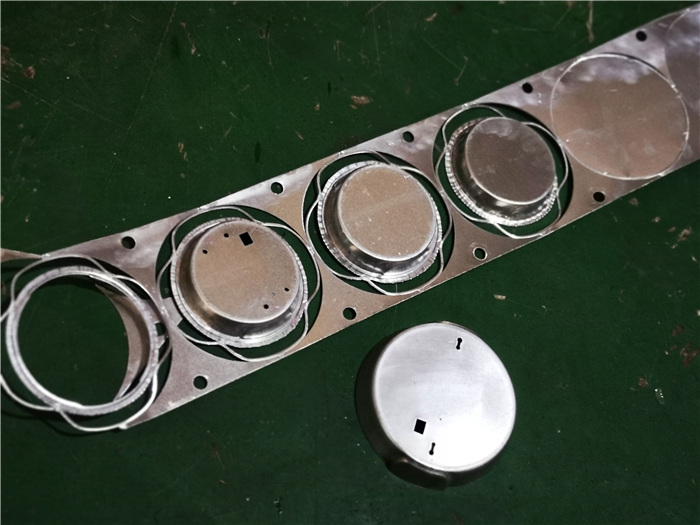

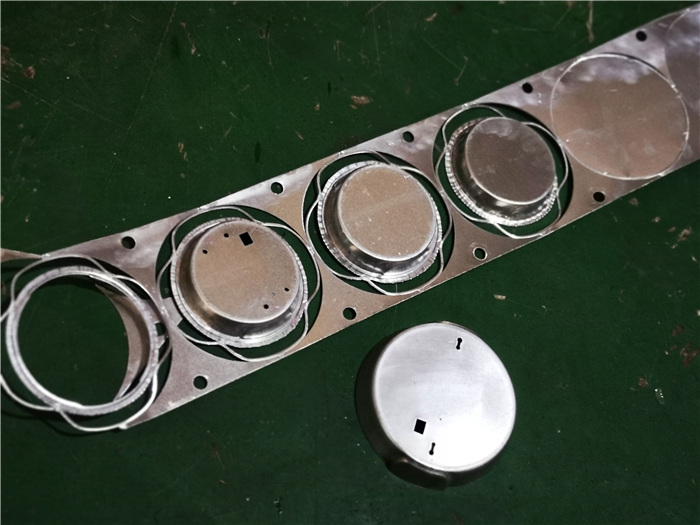

Aluminum Stampings

Stainless Steel Stampings

Metal Stampings

Automotive Stampings

Long Run, High Speed Stamping

Progressive Die Stampings

Single process Stamping

Compound Stamping

Deep drawing stamping

Components stamping we produce through our customs precision metals

stamping including:

Electronic connectors,Heat sinks,Transfer stampings,Printer

cartridge blades,Medical components,Die insert ,Furniture

parts,Sensor components,Thrust washers,Spring metal parts

We have invested in a range of capabilities to lower your cost,

speed new parts development, and capability with your needs. Our

press capabilities range from small part to big part.

Our quality team assures compliance and works with our production

team to assure conformance with your requirements, our internal

standards, and the requirements of our various external

certification bodies.

Our production and quality QC measuring with optical comparators,

multiple high-precision Zeiss measurement machines, and

high-precision gauge construction and maintenance capabilities.To

make sure customer demand.

| General Capabilities | Design Modeling (2-D, 3-D) | Die Location Technical Support | Inspection | | Detail Tooling Documentation | DFMEA/PFMEA | Quick Building Prototypes | | Die Types | Forming Dies | Precision Progressive Stamping Dies | Secondary Dies | | High Speed Steel Dies | Precision Blanking Dies | | | Tooling Material | Carbide(CD650,V3,KD20) | ASP-23 | ASP-60 | | S55C---45#55 | AL7075 | SKD11 | | Tooling Life | 50 Million to 300 Million Times | | Die Concept | 2-Plate Die | 3-Plate Die | Module Die | | Production Equipment | CNC | SODICK Nice Surface EDM | P/G | | Drill | SODICK Wire Cutting Machine | J/G | | Milling Machine | WAIDA Profile Grinder Machine | | | Stamping Equipment | AIDA | PURDER | KYOL | | MICO | | | | Stamping Product | Custom Stamping | SIM Spring | Spring | | Battery Spring | Shield Drawing | Press-Fit Terminal | | Lead Frame | Power Terminal | PC Terminal | | Additional Services Provided | Custom Packing | Packaging | Heat Treat | | Plating | | | | Delivery | 3-6 Week | 4-8 Week | | |

|

FAQ

Q: What’s your manufacture capability?

---- We use Sodick/Charmilles to frabricate die inserts,dimension

we can do is +/-0.005mm.

Q: Can you make all the dimensions are according to our

design/sample?

---- We can guarantee that all the dimensions are made according to

your drawing/sample.Please notice that dimension tolerence we can

do is +/-0.003mm.

Q:Did the stamping die suit for my press machine?

---The stamping die is made according to your press machine’s

specification.Before start making die parts,we will send the design

for your approval.

Q:What’s your advantage compare with other supplier’s on the

market?

----We are stamping factory,have a team contains die

design,making,maintance and stamping production.We know how

important the good mold for stamping production.

----All our engineers are with more than 10 years working

experience.They are more professional on precision stamping field.

----All the die parts we made are by Slow-speed wire EDM,can

gurantee the dimension.Many of them make it by middle-speed wire

EDM/fast-speed wire EDM