Anping Dixun Wire Mesh Products Co., Ltd |

|

Verified Suppliers

|

|

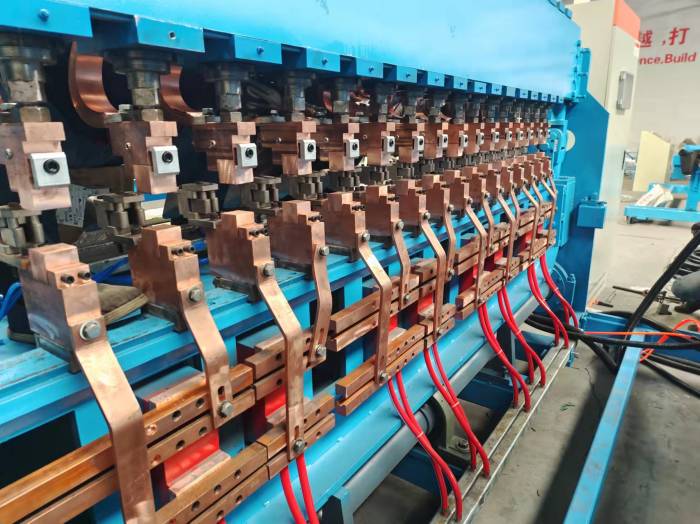

Schneider Switch Bridge Construction Reinforcing Mesh Welding Plant

Reinforcing Mesh Welding Plant Introduction:

1. Main welding machine

1. The main welding machine is a device to form a welding spot by welding and pressing the positioned line wire and cross wire.

2. Adopt accurate casting grooves, modularized installation of electrode to ensure the precision of mesh.

3. The line groove has the function of elastic lifting , enable to reducing the wear of the electrode block effectively ,extending the working life of electrode.

4. With cross line detection device to ensure that the position of the wire fallen is accurate.

2. Automatic line wire feeding

The automatic line wire feeding is to automatically feed the manually thread line wire to the welding electrode position of the main welding machine, so that the main welding machine can complete the welding process. When the trolley automatically feeds, the next set of line wire is manually prepared to achieve non-stop production of the main welding machine and improve production efficiency.

3. Cross wire hopper

1. Cross wire hopper is a feeding device that it can according to welding needs putstraightened and cut off fixed length steel into the welding electrodes position/location of main machine .The greatest feature of the hopper is that it has cross wire stock bin and auto.feeding device,the loading capacity is 1.5 tons or so ,it can reduce the amount of material take manually and improve production efficiency.

2. This cross wire hopper is made up of platform ladder,stock bin,wire fallen hopper and are installed in round-trip mesh pulling shelf.

3. Wire falling hopper makes use of the disc-shaped sheave for precise twisting , according to the welding needs, each cross wire is evenly fed into the pusher position one by one, The wire holding motor is 13.5N.m stepping motor.

4. Mesh pulling device

1. CNC servo mesh pull cart is to pull have welded cross wire out of the grid according to the parameters set by the program,and it can realize mesh pulling in round-trip according to the length of the mesh until whole mesh was pulled entirely.

2. The CNC servo mesh pull cart consists of four parts: a mesh pulling undercarriage, a movable mesh pulling rack, a mesh pulling cart, and mesh supporting tubes.

3. The joint between the removal rack and undercarriage has one set mechanical anti-lock device,and it can improve safety for operators.

5. Fast speed mesh pulling device

CNC servo mesh output unit is to send out of the mesh to quickly transfer to the automatic mesh fallen position and to prepare adequate pulling space for the subsequent mesh welding.

6. Automatic falling device

Automatic mesh fallen replace manpower output mesh, reduces manpower effectively, improves production efficiency.This device is a lifting working platform. At the initial period, the platform is at the highest position. With the increase of mesh, the platform keeps falling until it stops at the same height as the transmission platform, and then the meshes are sent out by the automatic transmission chain.

7. Automatic output device

1. Automatic output device, driven by motor chain drive, so that the mesh will be shipped out, convenient for manual lashing and handling.

2. This mesh output device is installed in two parts, one under the falling frame and the other behind the frame. Driven by two separate motors .

3. The spacing of the support chain is automatically adjusted with the mesh fallen mechanism.

Reinforcing Mesh Welding Plant Technical Parameters:

| Wire diameter | 5-12mm |

| Mesh width | 2500mm |

| Mesh length | 6m or 12m |

| Line wire space | 100-250mm |

| Cross wire space | 100-250mm |

| Pulling mesh system | By servo motor |

| Number of welding electrode | 24pcs |

| Welding transformer | 150kva*12pcs |

| Machine weight | 10T |

| Machine dimension | 20*3.2*2.2m |

| Line wire feeding | Manual feeding |

| Cross wire feeding | Controlled by stepping motor |

| Manpower | 3 persons |

| Required floor space | 40*10m(length*width) |

| Power transformer supply | 300kva |

Reinforcing Mesh Welding Plant Applications:

Engineering construction, campus construction and hospital construction need steel mesh, steel mesh is welded from steel.

Reinforcing Mesh Welding Plant Photos: