Anping County Anhesheng Hardware Mesh Products Co., Ltd. |

|

Mist eliminators are typically installed at the top of the column, or used in conjunction with collection trays from one packed bed to another. The mechanical properties of the mist eliminator are measured by two curves: collection efficiency versus particle size, and pressure drop versus steam load. To operate efficiently, mist eliminators should be equipped with fiber or mesh pads with a high surface area-to-volume ratio. They separate liquid particles from the gas and minimize liquid entrainment from the column or the effluent gas flowing from one packing to another.

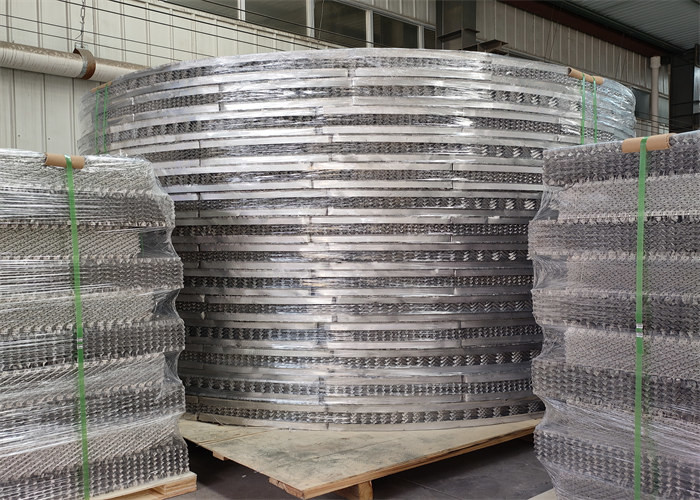

Stainless steel wire mesh demister material: 201 304 304L 316 316L 321 2205 904L etc.

Mist Eliminator Application

Existing mist eliminators installed in large-diameter process columns/separators allow droplets in the liquid/vapor stream to enter the downstream compressor. As the droplets pass through the compressor, the droplets evaporate, leaving a solid deposit on the hot end of the compressor wheel. Over time, deposits build up and slough off the impeller, causing the impeller to become unbalanced and vibrate, resulting in downtime for critical units in the process.

1. Refinery vacuum distillation column. Wire mesh demisters allow

operation at higher flow rates and improve oil and gas quality when

deep cutting atmospheric heavy oils.

2. Absorption tower. Wire mesh demisters can achieve complete

removal of all kinds of mist-absorbing oil, glycol, and amine

solutions, resulting in clean, dry gas.

3. Evaporator. Wire mesh demisters avoid entrainment losses of

valuable products and produce high-quality condensate (water)

suitable for boiler feed water or for use in production processes.

4. Distillation column. Wire mesh demisters can improve product

performance in the treatment of vegetable oils, tall oils, fatty

acids, glycerol, lubricating oils, mineral oils, and the extraction

of propane from bitumen, organic intermediates, refined chemicals,

etc.

5. Dust collector. The wire mesh demister has the same dust removal

effect as the wet dust collector, etc.

| Type | Operating mechanism | Assembly | Function | Remarks |

| Settling tank knockout drum | Gravity | Tank (upright or horizontal) | Slowing down the gas flow so much that the settling velocity is higher than the gas velocity. | Simple, inexpensive apparatus for very gross drops, poor efficiency, rare use. |

| Fiber filter filtering candle | Mechanical filter | Case with compact packing of fibers on different single or individual filtering candles | Single drops are brought in touch with the fibers, flow together, increase and fall down due to gravity. The filtering candle prevents the passing of droplets while gas flows through. | Voluminous apparatus with very low face velocity and low liquid loading preferably for very small drops; the danger of clogging and build-up. |

| Electrostatic precipitator | Electrostatic forces | Case with electrodes | The drops are electro-charged and attracted to the collecting electrodes. | Complicated, expensive apparatus for extremely fine drops, very high efficiency, rare use. |

| Cyclone | Mass moment of inertia | Tank with the installation which forces the gas flow to rotate | Based on rotation separation because of varying density, the drops are eliminated along the tank walls. | Simple and voluminous apparatus for middle-sized drops, good efficiency, frequent use. |

| Wire mesh | Mass moment of inertia | Tank with a pack of several layers of wire mesh of undulating wires; compact wire mesh with high porosity | The drops are brought in touch with the wire surface, flow together, coalesce and fall down due to gravity. | Voluminous apparatus with low face velocities for low liquid loading and very fine drops, the danger of clogging and build-up. |

| Impingement eliminator | Mass moment of inertia | Tank with a set of profile plates of different types | Gas flow is split up into many single flows and repeatedly deflected. Due to inertia, the drops cannot follow the flow of the gas and thus are eliminated on the impingement surfaces. | Small compact construction because of high face velocity, very high efficiency even for very fine drops, low-pressure drop on well-formed profiles, and increasing use. |

| Type | Specification | Surface Area m2/m3 | Free Volume% |

| SP | 40-100 60-150 105-300 140-400 160-400 200-570 | 529.6 | 0.9788 |

| DP | 60-100 80-100 80-150 90-150 150-300 200-400 300-600 | 625.5 | 0.9765 |

| HP | 20-100 30-150 70-400 100-600 170-560 | 403.5 | 0.9839 |

| HR | 33-30 38-40 20-40 26-40 30-40 30-50 48-50 30-60 30-80 50-120 | 291.6 | 0.9832 |

Company Profile:

Anping County Hardware Mesh Products Co., Ltd. is located in Anping County, Hebei Province, known as the "Hometown of Chinese Wire Mesh". The company is a dedicated manufacturer of wire mesh demisters. The company has more than 90 sets of knitted mesh equipment. The wire mesh demister is the main product of our company. Most of our employees are operation, maintenance, and installation personnel with practical experience, who can provide customers with the required engineering consultation and installation of tank filtration. solution.Nearly 20 years of experience producing mist eliminator mats, knitted wire mesh, and other packaging materials.

We have ISO9001 certification and a strict quality control system

in the QC department of the enterprise.

We claim that all mist eliminator pads our customers receive are

qualified and perform flawlessly. We have different specifications.

The filtration fineness can reach 3μm~5μm. In addition to standard

and popular sizes, we can also customize specific applications

according to customer needs.

Through continuous on-the-spot inspections, personal exchanges and

cooperation with customers, and comprehensive discounts and

technical support, we have won strong customer support and praise

during the company's development.

The company's performance has maintained an annual output value

growth rate of 30-40. Our employees pursue the policy of

"enterprising, truth-seeking, rigorous and united", continue to

develop and innovate, take technology as the core, and

wholeheartedly provide you with cost-effective products,

high-quality engineering design, and services.

Welcome customer consultation and I sincerely look forward to

cooperating with you!