Shandong Huarui Electric Furnace Co., Ltd. |

|

Verified Suppliers

|

|

China transistor medium frequency induction melting furnace system (third generation) with new IGBT dual unit

China energy-saving transistor induction melting furnace system with high efficiency

New generation IGBT dual unit module frequency electric furnace is currently approved as the most energy-saving medium frequency furnace, it can save 5% of power consumption higher than thyristor type serial-connected furnace because it rejects the current-commutating inductor inside thyristor-inverting electric furnace.

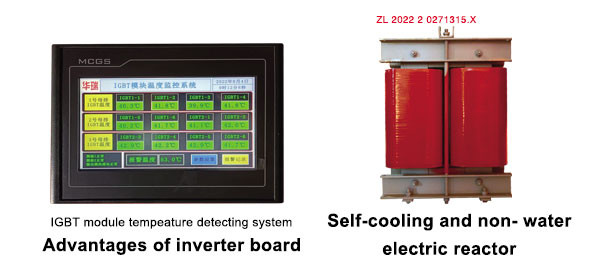

Low maintenance cost. For Huarui's IGBT module medium frequency electric furnace , one drive board drives one module, ensuring its reliability is much higher than that of the past single tube IGBT medium frequency furnaces. Even if short circuit, ignition, steel penetration or water cable breakage due to burning happen to furnace, IGBT can’t be damaged any more, solving the problem that all IGBT modules of old single transistor type were damaged if one part is damaged , so this greatly reduces maintenance costs.

It has many advantages such as strong durability, low operating noise, high over-load capacity, no special requirements for working environment, simple operation and low maintenance cost.

Technical Features

1.IGBT is a complex of power transistor (GTR) and power effect transistor (MOSFET), it combines advantages of GTR and SFT, so it has excellent performance.

2.IGBT medium frequency power supply unit adopts a kind of circuit that capacitor connects inductor in serial-connected form, Due to frequency inverter and power regulation mode, rectifier bridge is in an uncontrolled state with a power factor over 0.97 and harmonics are low during operation.

3. Compared with thyristor, IGBT transistor can not only control conduction, but also can control its turn-off action at will , however, thyristor must be passively turned off and require time to finish this action, this makes inverter power factor of IGBT transistor type much higher (≥ 97%)and furnace voltage much higher as well under the same input voltage(380V) , and IGBT inverter voltage is around 2800V, however inverter voltage of traditional thyristor is only 750V and maximum 800V, so inverter voltage is four times higher than that of thyristor type, besides, wiring line loss is low and 15% energy can be saved.

4. Compared with traditional thyristor, constant power output is another important advantage of IGBT medium frequency power supply frequency and power inverter system, approximate constant power output is kept throughout the entire smelting process without being affected by the amount of raw material inside furnace or thickness of furnace lining wall. For traditional thyristor medium frequency power supply system, heating process is affected by magnetic induction volume change. Initially, melting power is so low that melting speed is not quick . Power of thyristor power supply varies according to melting time and magnetic induction volume, power gradually increases from low value to high value, reducing capacity utilization of transformer and increasing production costs. ,from this point of view, IGBT type can save energy by 3% to 5% or so.

Technical Data:

Induction melting furnace power supply, thyristor serial-connected inverter medium frequency power supply , one power supply cabinet drives two furnaces

| Type | DX-2000Kw |

inlet power supply ( V) | 380V/ six phases |

inlet current ( A) | 1630A |

Direct current voltage (V) | 1000 |

Direct current (A) | 2000 |

medium frequency voltage (+-10%) V | 2400 |

medium frequency (Hz) | 100-400Hz |

medium frequency power (Kw) | 2000KW |

Accessary Advantage:

New generation IGBT medium frequency furnace technology is a kind of control technology that our company has been dedicated to researching and developing since 2017, it is at the international leading level. This technology is developed on the basis of Infineon's fifth generation IGBT module and it has a epoch-making significance.