MEEKARE GMC4022 Gantry Milling Machine Center good price High

Quality

Structure and Performance

This machine is a fixed beam of gantry CNC boring and milling

machine, have X, Y, Z axis three NC axes, and three axes can

realize automatic positioning, also can realize three axis (X, Y,

Z) linkage, can do milling, drilling, reaming, boring, tapping etc

work. This machine has advanced design, beautiful appearance, good

integral rigidity and long time precision maintain, wide

application range etc. advantages. It’s widely used in large diesel

machinery, agricultural machinery, chemical machinery, new energy,

rail transit, automobile, mining machinery, steam turbine, light

textile, aerospace, military industry, ship, power, nuclear

industry, metallurgy and so on.

Technical Parameters:

| Model | | GMC4022 |

| Worktable | Dimension (L*W, mm) | 4000*1800 |

| Max load (Kg) | 16000 |

| T slot (slot number-width*pitch, mm) | 9-22*200 |

| Machining Range | Gantry width (mm) | 2230 |

| X/Y/Z Axis travel (mm) | 4200/2200/1000 |

| Distance from spindle nose to worktable (mm) | 310-1310 |

| Feed System | CNC system | Japan Mitsubishi M70A/ Fanuc Oi MD |

| X/Y/Z Axis fast shift (m/Min) | 10/12/10 |

| Max cutting feed speed (m/Min) | 7 |

| ATC (CNC Milling Machine don't include it.) | Standard tools number | BT50 / 32 |

| Max tool diameter/ length (mm) | Φ125/300 |

| Tool change method | Pneumatic |

| Max tool weight (kg) | 18 |

| Accuracy | Positioning accuracy (mm) | 0.021 |

| Repeat positioning accuracy (mm) | 0.02 |

| Guide rail Form | X/Y/Z Axis guide rail | 2-55(X) / 2-55(Y) / Z: Hard rail |

| Spindle System | Spindle specification (mode/installation diameter) | BT50/Φ200 |

| Spindle speed (rpm) | 4000 |

| Spindle motor power (KW) | 22/26 |

| Air Pressure | Air requirement (kg/cm2) | ≥6 |

| Air flow (m3/Min) | ≥0.5 |

| Machine Specification | Net Weight (Kg) | 37000 |

| Overall Dimension (mm) | 9900*4650*5170 |

As our company keeps developing and improving our products, this

sheet is only for reference. Our company reserves the right of

improving products' design and specifications without notice. "()"

is optional.

1. Main material and stiffened plate layout

(1) Castings: bed, worktable, column, cross beam, Y axis carriage,

ram etc. are made of high strength, low stress casting iron and

resin sand molding process, and after heat treatment, the internal

stress is eliminated, to get good overall stable structure. With

the characteristics of high strength, good rigidity, small heat

effect and excellent seismic performance, machine’s overall

precision is guaranteed for a long time. To prolong the service

life.

(2) Stiffened plate: Use FEM 3D finite element analysis technology

to optimize the design and arrange the reinforcement plate

reasonably, so as to maintain the overall stability of the

structure for a long time, so as to ensure the overall accuracy and

prolong the service life of the machine in long term.

2. Spindle unit

(1) Spindle drive: FANUC high power, high torque generalized

spindle motor, and high precision Taiwan spindle synchronous belt

drive.

(2) Spindle rigidity: Spindle is located at the center of the Z

axis ram, and the core rod grinding process with the ram inner hole

has excellent rigidity to meet the strong cutting. Spindle tool

loosen and broach: Use a special hydraulic cylinder to complete the

spindle automatic tool loosening, spindle automatic broach is

completed automatically by the butterfly reed.

3. CNC axis servo drive and guide track composition

(1) X, Y, Z axis direct connection drive: FANUC AC servo motor, and

large torque synchronous belt pulley, and high precision JIS-C3

ball screw (ball screw and nut to take pre tightening, full travel

check, clearance elimination) transmission structure, to realize X,

Y and Z three way feed.

(2) X, Y axis guide rail: Use high rigid roller linear sliding

guide rail, has the advantages of good dynamic characteristics,

large load bearing capacity, high running accuracy, no crawling at

low speed, and small friction resistance.

(3) Z axis guide rail: Hard guide rail. Through the high frequency

quenching heat treatment process on the slideway guide rail

surface, the surface roughness and surface hardness are obtained

through rail grinding, and then the sliding guide is made with the

Y axle trailing board (polytetrafluoroethylene PTFE).

FANUC system can open AICC high speed, high precision, five axes

four linkage functions

Taiwan precision high rigidity BT50 spindle, with Japanese FANUC

18.5kW large torque / high power spindle motor (Optional: German ZF

high and low gear box gear box -1:4 & 1:1)

Max spindle output torque : 944 Nm

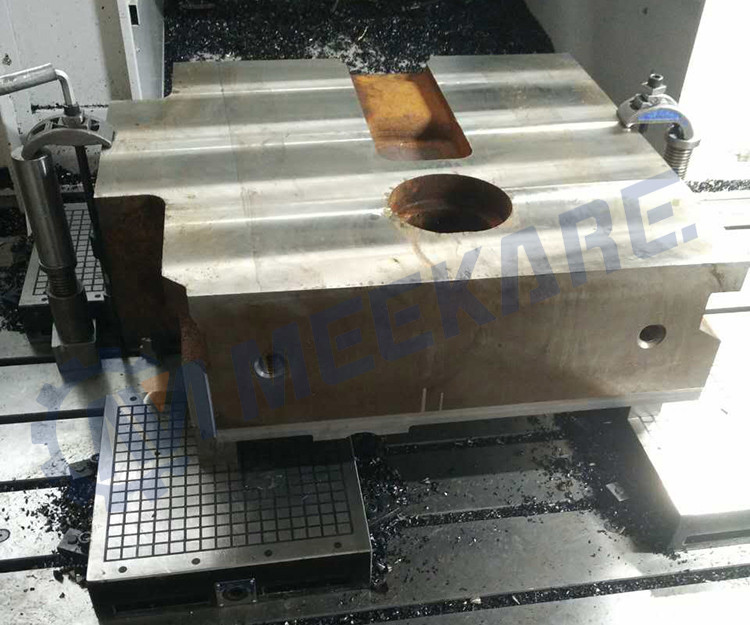

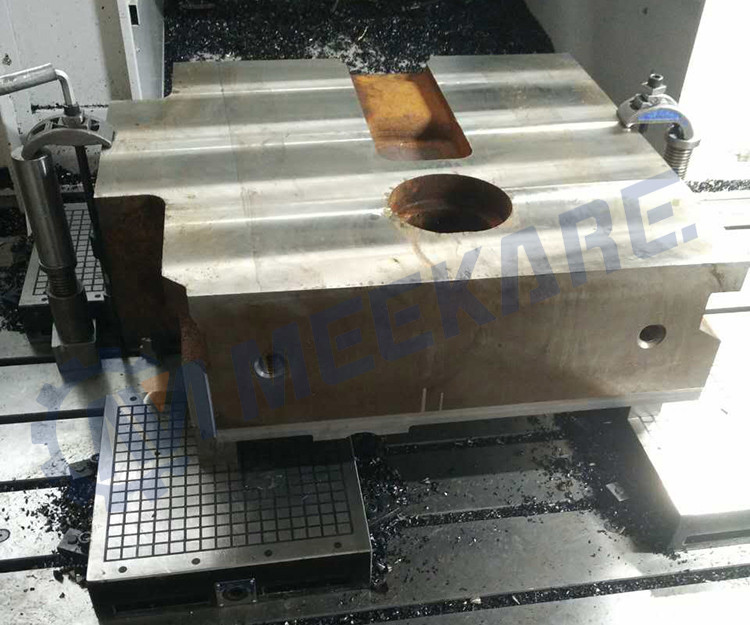

Photos

Application Cases

Packing

What We Provide

- CNC Tapping Machine

- CNC Machining Center (Vertical, Gantry type)

- High Speed CNC Engraving and Milling Machine

- EDM Wire Cut Machine (Middle speed, Fast speed, Large taper)

- CNC Spark Machine

- EDM Small Hole Drilling Machine

- Universal Testing Machine (Tensile Testing Machine)

- Environmental Simulation Equipment (Aging Oven)

- Other non-standard machine

- Machining Service

View Our Website

www.meekare.com

Contact Us