BLOOM(suzhou) Materials Co.,Ltd |

|

Verified Suppliers

|

|

Pvc Screw And Barrel With Flange For HDPE Bimetallic Screw And Barrel For Pvc Machinery Parts

1 . Description

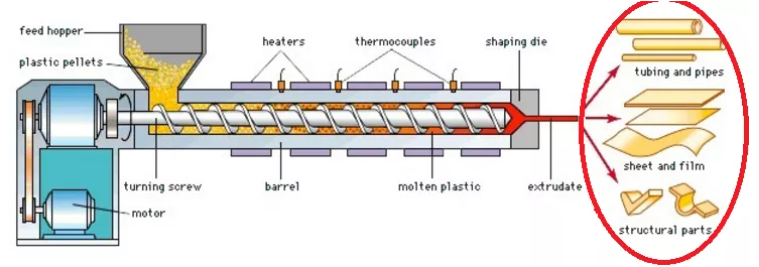

The PVC Screw and Barrel with Flange for HDPE and Bimetallic Screw and Barrel for PVC Machinery Parts are two types of extruder screw and barrel components that are designed for processing PVC (polyvinyl chloride) and HDPE (high-density polyethylene) plastic materials. These components are important parts of plastic extrusion machinery used to manufacture a wide range of plastic products, including pipes, tubing, profiles, sheets, and other plastic products.

The PVC Screw and Barrel with Flange is designed specifically for processing PVC materials. It has a tight screw pitch and a high screw speed, which generates high shear forces that are necessary for melting and processing PVC materials. The screw and barrel are typically made from high-grade alloy steel and undergo special surface treatments such as nitriding or bimetallic coatings to increase their wear resistance and durability. The flange design allows for easy attachment to the extruder machine.

The Bimetallic Screw and Barrel is designed for processing a variety of plastic materials, including PVC and HDPE. It has a bimetallic construction, with the base material made from high-quality alloy steel and the outer layer made from a wear-resistant material, such as tungsten carbide or a nickel-based alloy. This construction provides the screw and barrel with high wear resistance and durability, which is important for processing abrasive plastic materials, such as PVC.

Overall, both the PVC Screw and Barrel with Flange for HDPE and the Bimetallic Screw and Barrel for PVC Machinery Parts are high-quality and reliable components that ensure consistent and efficient processing of PVC and HDPE materials for various plastic extrusion applications. Their wear-resistant construction and efficient design make them popular choices for plastic extrusion manufacturers who require high-quality products with high production rates and long service life.

2 . Comparsion of the output (LDPE)

Pressure is generated if resin passes over the barrier, forcing any air in the melted resin back to the feed side and effectively preventing the intrusion of air bubbles on the sub flight side. This is highly effective with resins that generate bubbles such as PS, PA, PET and EVOH.

3 . Parallel twin screw and barrel application

1)PP

2)PE

3)PVC

4)WPC

5)SHEET/PIPE/PROFILE/ FOAM BOARD

6)CRANULAR TWIN SCREWS EXTRUDERS

4 . As per customer's demand,we can also supply below:

PVC/PE Film Blowing Screw;

Blow Molding Screw;

PS/PE/PP/ABS Sheet Extrusion Screw;

PE Aluminum Plate;

PPR Pipe Screw;

EVA Extrusion Screw;

HDPE High efficiency Screw;

PET Straps Screw;

XPS/EPE Foamed Screw;

Granulation Screw,Vented single screw etc.