Qingdao Luhang Marine Airbag and Fender Co., Ltd |

|

Verified Suppliers

|

|

Rotation around Steel Pile Polyurethane Foam Filled Donut Fender

Qingdao Luhang is a professional supplier of foam filled donut

fenders with developing and manufacturing capacity. Foam Filled

Donut fenders are designed to float up and down with the tide on a

circular mono-pile either driven into the bed or mounted on the

face of a quay wall. Donut fenders are suited for lock entrances,

turning structures, approach channels and breasting dolphins. Not only do Donut fenders rise and

fall with the tide but due to the low friction guides located

inside the fender they also rotate around the pile assisting in

lining up vessels for mooring or guiding though a channel.

Structure and Constrution of Foam Dunut Fenders

Applications of Donut Fenders

1. Breasting dolphins

2. Corner protection

3. Guiding structures

4. Locks and dry dock entrances, corner protection, turning

dolphins, areas with large tidal variations or bridge protections

5. Other monopile structures

6. Submarine jetties

Characteristics and Advantages of Foam Donut Fenders

1. Proportional load deflection curve

2. Low shear forces

3. Self-adjusting to changing water levels

4. Low installation costs

5. Generally maintenance free

6. Individual drafts can be controlled by counterweights

Sizes and Performance of Foam Donut Fenders

The performance of the standard size Donut fenders given below

represents a small selection of sizes selected to give an

indication of the performance of a fender as a guide only.

| Pile Diameter (PD) | Outer Diame- | Vertical con- | Energy Ab- | Reaction | Energy Ab- | Reaction |

| 500 | 1000 | 3000 | 14.7 | 224.6 | 24.5 | 374.7 |

| 600 | 1200 | 2000 | 13.7 | 179.5 | 23.5 | 300.2 |

| 600 | 1200 | 3000 | 21.5 | 269.6 | 34.3 | 450.2 |

| 900 | 1800 | 1000 | 15.7 | 135.3 | 26.4 | 224.6 |

| 900 | 1800 | 2000 | 32.3 | 269.7 | 51.9 | 450.2 |

| 900 | 1800 | 3000 | 48 | 405.1 | 78.4 | 674.9 |

| 1250 | 2500 | 2000 | 61.8 | 374.7 | 100.1 | 624.8 |

| 1250 | 2500 | 3000 | 92.2 | 562.1 | 151 | 937.8 |

| 1250 | 2500 | 4000 | 123.6 | 750.4 | 201.1 | 1249.7 |

| 1500 | 3000 | 2000 | 89.2 | 450.2 | 144.2 | 750.4 |

| 1500 | 3000 | 3000 | 133.4 | 674.9 | 200.6 | 1125.2 |

| 1500 | 3000 | 4000 | 177.5 | 899.7 | 289.4 | 1509.7 |

| 2000 | 4000 | 2000 | 157.9 | 600.3 | 257 | 999.6 |

| 2000 | 4000 | 3000 | 236.4 | 899.5 | 385.5 | 1499.9 |

| 2000 | 4000 | 4000 | 315.8 | 1199.7 | 514.1 | 2000.3 |

Generally Donut fenders are designed on a project by project basis

taking into consideration the required berthing energy requirement

and the size of the pile the fender will be installed on. The

installation pile can either be existing or if new then the final

size of the fender can be determined taking into consideration

movement and therefore energy absorption of the pile.

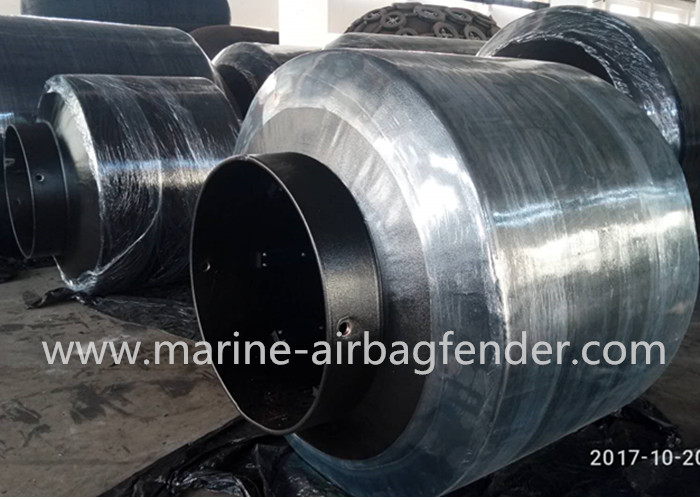

Pictures of our Foam Donut Fenders

How to install the donut fenders?

Installation of our Donut Fenders is very easy. The fenders will be delivered to site ready for installation on the fender piles. Once lifted over and lowered onto the fender pile the fender should be ready for use. Ballasting or trimming is not required as the fender will float at the designed level. Finally a capping feature can be placed over the top of the fender pile to finish the installation off. Maintenance of our donut fenders is very low as the internal bearings are designed to allow the fender to rotate and float up and down with the tide for a period of 25 years.

Any additional equipment installed with the donut fender such as secondary fenders or mooring points should be maintained separately.

How to Select and Order Suitable Foam Donut Fenders?

Generally Donut fenders are made to measure.

We have therefore given the dimensions, weight and performance

(table on previous page) in groups of sizes designed to be an

indication of performance only.

Precise design and finalised dimensions can be calculated with

project specific pile dimensions and berthing energy/reactive load

requirements.

Please just drop us a message here below or send us an email with

your requirement for a detailed design to suit your requirements.