yixing xinwei leeshing refractory materials co.,Ltd |

|

Verified Suppliers

|

|

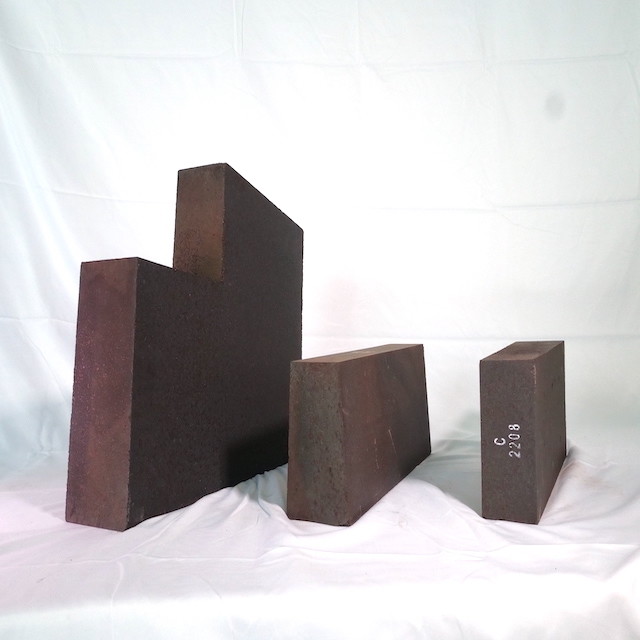

Glass Kiln Furnace Refractory Fire Fused Cast Azs Zircon Corundum kiln refractory brick

Product Description

Fused Cast AZS block as an important role used in Glass Furnace is made of pure alumina powder and zircon sand and is composed of three main chemical components of Al2O3, ZrO2 and SiO2,most widely used materials both in glass contact and superstructure of glass melting furnaces. The products are made of high pure material, fired at high temperature by advanced technology, with the advantages of high strength, high compression resistance, good thermal shock resistance, good performance in high temperature, good thermal conductivity,excelerosion resistance and used for linings of furnace in glass industries.

Features

Dense micro structure

Strong resistance for high temperature and glass liquid

Good thermal shock resistance

High compression resistance

Wear and slag erosion resistance

Shapes & Sizes Of Fused Cast AZS Block

Applications

Fused Cast AZS are the most widely used materials both in glass contact and superstructure of glass melting furnaces.

Specifications

Zircon contents range from 30% to 40%

Widely used throughout metallurgical industry

| Index | Directed Bonded Magnesite-Chrome Brick | |||||||

| DMC-B | DMC-C | |||||||

| DMC12B | DMC9B | DMC6B | DMC4B | DMC20C | DMC18C | DMC16C | DMC12C | |

| MgO% | ≥65 | ≥75 | ≥80 | ≥82 | ≥55 | ≥60 | ≥65 | ≥70 |

| Cr2O3% | ≥12 | ≥9 | ≥6 | ≥4 | ≥20 | ≥18 | ≥16 | ≥12 |

| SiO2 | ≤2.0 | ≤1.8 | ≤1.5 | ≤1.5 | ≤2.5 | ≤2.4 | ≤2.4 | ≤2.0 |

| Refractoriness Under Load 0.2MPa℃ | 1680 | 1680 | 1650 | 1650 | 1700 | 1700 | 1700 | 1680 |

| Apparent porosity% | ≤18 | ≤18 | ≤17 | ≤17 | ≤18 | ≤18 | ≤18 | ≤18 |

| Cold Crushing Strength Mpa | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 |

| Bulk density(Kg/m3) | 3050 | 3050 | 3000 | 3000 | 3150 | 3100 | 3050 | 3000 |

Thermal Shock Resistance (950℃ Air cooling ) | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Index | Semi-Rebonded Magnesite-Chrome Brick | ||||

| ZMC-35 | ZMC-28 | ZMC-20 | ZMC-18 | ZMC-15 | |

| MgO% | ≥50 | ≥55 | ≥55 | ≥66 | ≥60 |

| Cr2O3% | 35-37 | 28-30 | 20-22 | 18-20 | 15-18 |

| SiO2 | – | – | – | – | – |

| Refractoriness Under Load 0.2MPa℃ | 1700 | 1700 | 1700 | 1700 | 1700 |

| Apparent porosity% | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 |

| Cold Crushing Strength Mpa | ≥45 | ≥45 | ≥45 | ≥40 | ≥40 |

| Bulk density(Kg/m3) | 3350 | 3250 | 3200 | 3100 | 3050 |

| Thermal Shock Resistance (950℃ Air cooling ) | 40 | 40 | 40 | 40 | 40 |

| China Rare Earth Holdings Limited ("CRE") (formerly known as Yixing Xinwei Holdings Limited) is one of the

leading and well-respected rare earth and refractory products

manufacturers in the Peoples' Republic of China ("PRC"). The Group

has been listed on The Stock Exchange of Hong Kong Limited since 15

October 1999. It is the first Chinese private enterprise which

engages in the manufacture of rare earth and refractory products

listing outside the Chinese mainland.

The Group operates a rare earth separating factory and a refractory production factory. The rare earth separating factory comprises a smelting rare earth products workshop, several rare earth extraction lines and many cutting edge equipment while the refractory production factory embraces a refractory products workshop with several high-temperature tunnel kilns, light tonnage brick pressers and pre-moulded production lines. The Group believes that the high quality production facilities could produce the best rare earth and refractory products.

The industrial applications for rare earth products include high-tech electronic devices, computers, electronic motors, LCDs, DVDs, magnetic materials, magnetic memory chips, fibre optics, superconductors, mobile phone batteries, precision optics and many energy-saving environmental protection products. Refractory products are used extensively in heat-treatment facilities for petrochemical, steel metallurgy, non-ferrous metallurgy, glass, construction materials, chemical fertiliser and ceramics industries. Rare earth products of the Group are mainly exported to the United States of America, Japan, Europe and Korea, and its refractory products are mainly for domestic sales and export to Japan. Its client list includes names of international prominence, such as General Electric, Nippon Electric Glass, Siemens, Shin-et Chemical and Krosaki Harima, to name but a few.

The Group has a research and development centre that focus on improving existing products and developing new products. Building and maintaining relationships with clients and exploring new businesses are the responsibility of its talented sales and marketing department. Concerning the environmental protection as well as the market needs, the Group will continue to develop environmental friendly and high value-added products. |

Our Services:

• Whole package refractory linings design for the kilns;

• Efficient and economical refractories recommendations;

• Provide the sample properties test report from authority

institute (SGS or CNAS);

• Kilns linings installation supervision, inspection, evaluation on

site;

• Offer measurement of the changes of the roundness in the rotary

kiln shell during operation (Ovality measurement).

• Cooperated research and development, provide the best suitable

products for different working conditions of the kilns;

• Has logistics company with great advantage in logistics and

shipping