JYC technology Co.,Ltd |

|

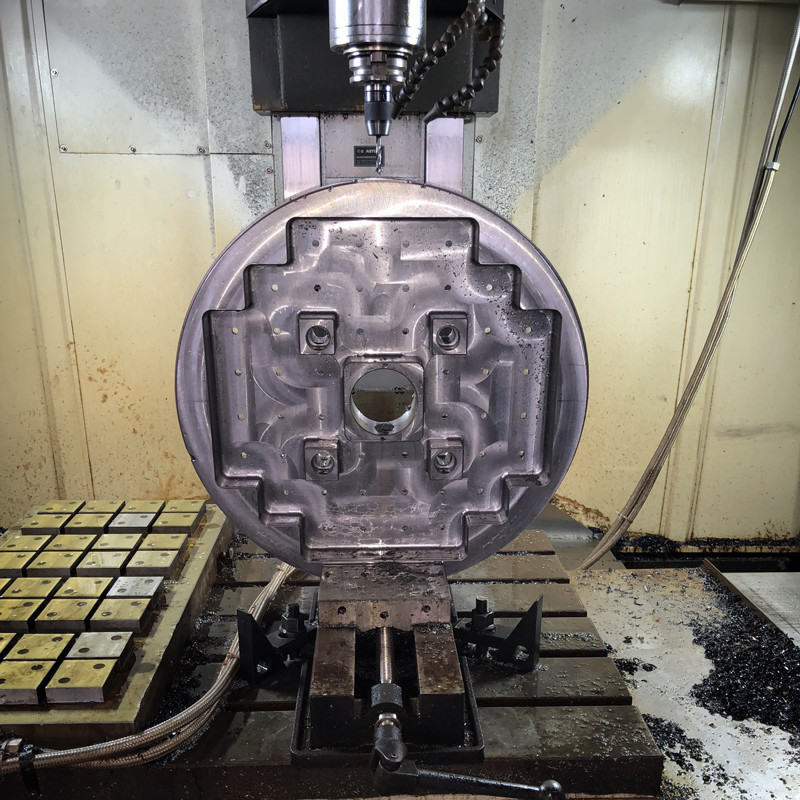

X71 circular electro permanent magnetic chuck

Product Introduction

X71 circular electronic controlled permanent magnetic chuck is designed with “multi-magnetic circuit and electric control”, its magnetism is adjustable. After magnetization, X62 does not need to continue to supply electric power. Electric power is supplied by quick connection or electric slip ring. Two clamps are accessible during the processing, work piece can be machined freely. It can really play the function “one clamping to complete three-sided processing”. X62 is suitable for work piece that not easy to clamp, such as thin wall parts, flange parts, shaped parts, etc. It is widely used on horizontal lathe, vertical lathe, vertical grinder, 5 axis machining center, turning and milling composite machine tool and so on."

Machining center sucker in the course of the work does not require electricity, rely on permanent magnet suction suction workpieces, to avoid the electromagnetic system in the sudden power failure and damage to the magnetic loss of the workpiece and the risk of falling off the workpiece. As the permanent magnet sucker only in the magnetization and demagnetization process within 1-2 seconds of the use of electricity, work without the use of any energy and produce safe, strong and efficient force, both economic and environmentally friendly.

This new type of CNC machining center disk in the instant power after the permanent magnet can be hardened workpiece positioning processing, the application of reverse current, you can demolish the workpiece removed, safe and energy saving, easy to operate, no temperature rise and change, processing accuracy high.

Strong support. In theory, the unit of permanent magnet fixture clamping force of 150KN, far greater than the cutting force, even the uneven surface of the fur, but also safe to suck, even if the milling quality of 52HRC hardened hardened workpiece, the same can normal work.

Product Parameters

Model | Dimensions(MM) | Polar Number | Channel Number | Voltage (V) | Max RPM [1/min] | Net WT (KG) | Overall size (CM) | ||

| φD | φd | H | |||||||

| X71-400 | 400 | 60 | 100 | 12 | 1 | 220/480 | 1000 | 98 | 50*50*20 |

| X71-500 | 500 | 60 | 100 | 12 | 1 | 220/480 | 800 | 150 | 60*60*20 |

| X71-600 | 600 | 80 | 100 | 12 | 1 | 220/480 | 650 | 220 | 70*70*20 |

| X71-700 | 700 | 80 | 110 | 12/16 | 2 | 220/480 | 600 | 290 | 80*80*22 |

| X71-800 | 800 | 120 | 110 | 12/16 | 2 | 220/480 | 500 | 390 | 90*90*22 |

| X71-1000 | 1000 | 200 | 120 | 16/24 | 2 | 220/480 | 400 | 660 | 110*110*22 |

| X71-1200 | 1200 | 250 | 120 | 16/24 | 2 | 220/480 | 320 | 950 | 130*130*22 |

| X71-1400 | 1400 | 300 | 130 | 18/24 | 4 | 220/480 | 260 | 1400 | 150*150*25 |

| X71-1600 | 1600 | 400 | 130 | 24/32 | 4 | 220/480 | 240 | 1850 | 170*170*25 |

| X71-1800 | 1800 | 500 | 130 | 24/32 | 4 | 220/480 | 160 | 2300 | 190*190*25 |

| X71-2000 | 2000 | 600 | 135 | 24/36 | 6 | 220/480 | 128 | 2900 | 210*210*26 |

| X71-2500 | 2500 | 800 | 135 | 36/48 | 8 | 220/480 | 100 | 4500 | 268*268*26 |

| X71-3000 | 3000 | 800 | 140 | 36/48 | 8 | 220/480 | 80 | 6800 | 318*318*26 |

| X71-3500 | 3500 | 1000 | 140 | 48/60 | 10 | 220/480 | 60 | 9500 | 368*368*26 |

| Note: Other specifications can be customized ,please call for further information. Suggestion: You can choose two installation methods (Quick plug/electric conductive slip ring). | |||||||||

| Permanent Magnetic Chuck | Electromagnetic Magnetic Chuck | Electro Permanent Magnetic Chuck | |

| Magnetic Source | Ndfeb | Coil and Core | Ndfeb Anico |

| Magnetic Force Principle | Internal Magnetic Fields | Constant Current | Conversion by Electronic Control Device |

| Usage | Manual | Electric Control Device | Electric Control Device |

| Precision | About 0.02-0 05 (the Error Increased Bysizes) | About 0.01-0.02 | About 0 002-0.005 |

| Potential Risk | Prone to Security Incidents | Prone to Security Incidents | Absolute Safety |

| Magnetic Regulation | Unable to Adjust | Electric Control Device to Adjustsuction | Electric Control Device to Adjust Suction |

| Suction | Small | Medium | Large |

| Residual Magnetism | More Remanence, Demagnetiz Ation Devicerequired | Less Remanence, Demagnetizationdevice Required | Automatic Demagnetiz Ation Withoutdemagnetization Device |

| Thermal Deformation | No | Continuous Power On, Heat Generationand Thermal Deformation | No |

| Applicable Workpiece | Thin and Small Workpieces | Thin and Small, Medium Sizedworkpieces | All Kinds of Workpieces |

| Application | Mainly Used for Grinding Machine | Mainly Used for Grinding Machine | For Grinding/milling/lathe Manchine and Soon. |

| Accessories | No | Electric Control Device | Electric Control Device |

| Serive Life | 3-5 Years | 6-10 Years | 20 Years |

Product Accessories

Magnetic Blocks

Use Magnetic Blocks to Machines 6 Sides of the Workpiece at Same Time. Blanks and Irregular

Workpieces Could Be Adjusted to Adapt to Their Roughness by Sliding Up and Down the Elastic Blocks, Toprovide Larger Magnetic Force.

More processing schemes can be provided by using different magnetic

guide blocks pardigm as below

PULSE CONTROLLER

Product introduction:

safety protection: The spindle linkage can be realized by unlocking the input contact signal and themagnetized output contact. lt is equipped with adjustable magnetoelectric current (or short circuit)protection and undercurrent (or circuit break) alarm functions.

Simple operation: all setting parameters and running state can be monitored through the host panel, andthe power frequency can be automatically tracked;Flexible configuration, easy to use.

control interface: it is equipped with a variety of alternative control interfaces, which can satisfy allkinds of on-line control requirements. It also has alternative control (remote) or PLC interfaces.

Install and Use

INSTRALL

Fixed In Clamp Slot

Secure With Screw Holes

MAGNETIZATION STEPS

1. Plug in

2. Press the

magnetization button

3. Until the green light isalways on

4. Unplug the plug andciose the cover

DEMAGNETIZATION STEPS

1. Plug in

2. Press the demagnetization button

3. Until the red light isalways on

4. Unplug the plug andclose the cover

FAQ

Q: Are you manufactory or trade company.