Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

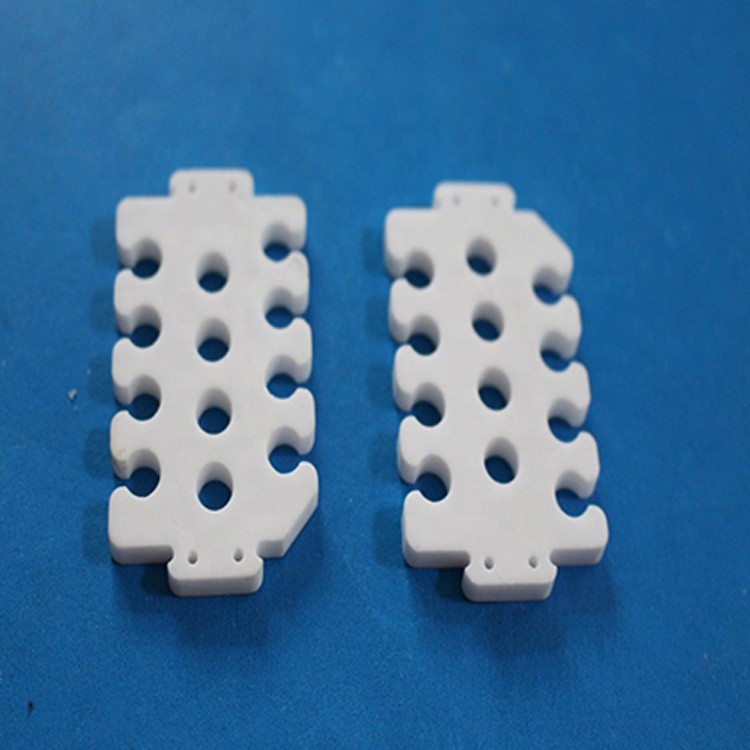

Aluminium Oxide (Alumina) is the most widely used ceramic material with near limitless manufacturing capabilities. They are grouped together based on purity levels, as the purity of Alumina’s increases wear and corrosion resistance also increases. LSP Industrial Ceramics stocks more alumina ceramic tubes than any other supplier. Our vast, readily-available inventory allows us to supply our customer’s ceramic tube needs immediately, even for hard-to-find or specialty products. Alumina’s are used in a variety of general-purpose applications, and their grade is chosen based on the application environment. Higher purity Alumina’s can be formulated for more demanding applications. Typical Applications Include: Wear resistant components, High pressure nozzles, Thermocouple tubes, Electrical Insulators, Corrosive labware, Furnace fixtures, Ballistic armor, Thread guides, Laser Tubes, and Pump seals.

Advantages of Alumina Ceramic

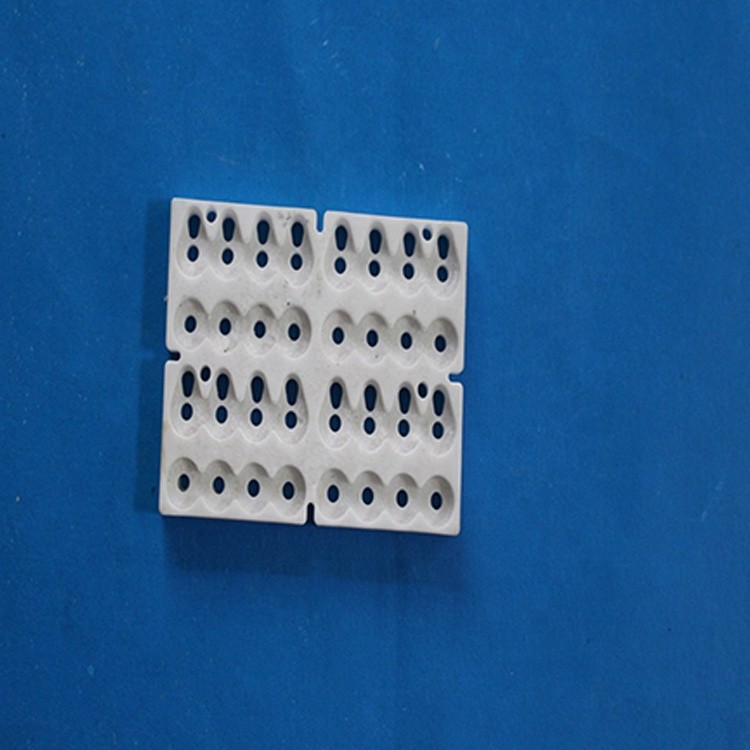

● High flatness and parallelism

● Compact and uniform microstructure with high strength

● Good permeability and uniform adsorption affinity

● Dressing easily, Fine pore size.

● Resistant to High temperature to 1000℃.

● High acid or alkaline corrosion.

● High strength

● Voltage resistance

● High Thermal Expansion

● Stable electrical performance characteristics.

● Good thermal conductivity

● Excellent Thermal Insulation; low thermal conductivity

● High resistance to crack propagation, high fracture toughness

● Ability to conduct oxygen ions

Application of Alumina Ceramic

● Pump components, valve components, flow components

● Vacuum Chucks

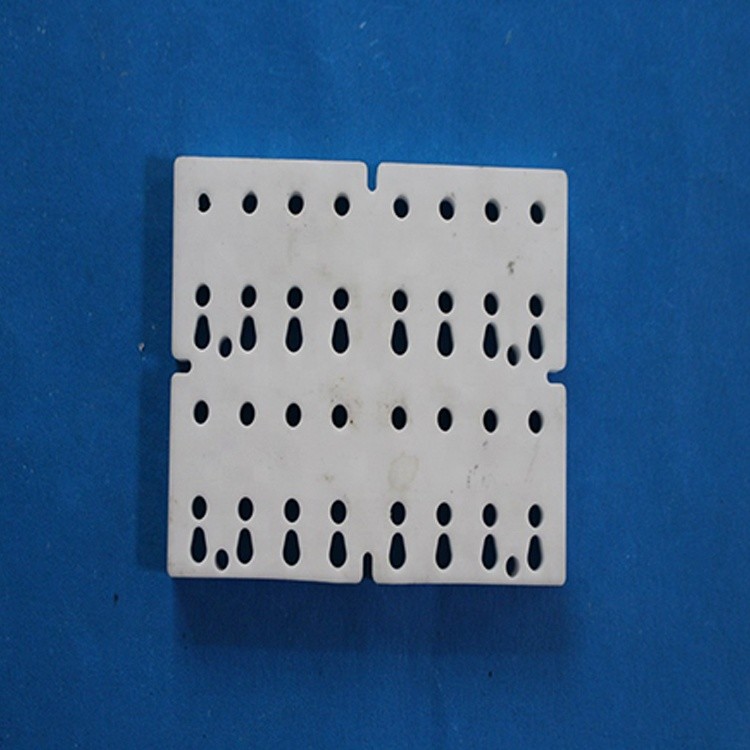

● Filters

● Oxygen Diffusers

● Air Bearings

● Permeable Substrates

● Dispersion Media

● Ash Handling

● Wicking Media

● Fluidized Bed Plates

● Specialty Spargers

● Breathers – Vents

| Alumina Ceramic Properties | 96% Alumina Ceramic | 99% Alumina Ceramic | |

| Item | Unit | Typical Values | |

| Physical Properties | |||

| Color | White | Ivory | |

| Density | g/cm3 | 3.7 | 3.85 |

| Alumina Content | % | 96% | 99% |

| Gas permeability | 0 | 0 | |

| Water Absorption | 0 | 0 | |

| Mechanical Properties | |||

| MONS' Hardness | Grade | 9 | 9 |

| Rockwell Hardness | HRA | 80 | 82 |

| Vickers Hardness (Hv50) | Gpa(Kg/mm²) | 15.7(1600) | 15.7(1600) |

| Flexural Strength(20°C) | Mpa | 300 | 330 |

| Compressive Strength(20°C) | Mpa | 2000 | 2000 |

| Modulus of Elasticity | Gpa | 275 | |

| Poisson's Ratio (20°C) | 0.22-0.23 | ||

| Fracture Toughness(20°C) | MPam1/2 | 3.5 | 4 |

| Thermal Properties | |||

| Thermal Conductivity(20°C- | W(m.K) | 25 | 27.5 |

| Thermal Expansion | 10-6/°C | 6.5-7.5 | 7.6 |

| Maximum Use Temperature | °C | 1600 | 1650 |

| Electronic Properties | |||

| Dielectric | KV/mm | >12 | >10 |

| Dielectric Constant | Er | 9-10 | 9.1 |

| Dielectric Loss Angle(1MHz) | 0.0002 | 0.0002-0.0003 | |

The use of ceramics is as old as the human race. Traditionally, they were molded and shaped into pottery and cast as bricks. The sturdiness and endurance of ceramic materials made them ideal for use in any climate or weather conditions. Modern advanced ceramics have been altered and engineered under exacting laboratory conditions to produce a wide variety of industrial products. The most prevalent of those products is Alumina Ceramics.

Do not find similar ceramic products on this page?

For more detail of ceramic products like price,shipping,samples...

Quick Free Quote . Our official E-mail: admin@cerampart.com(Mr admin).thanks

Delivery:

Custom OEM will be shipped within 15 days after determining the

parameters

The samples will be shipped within 3 days

Quick Delivery Via Fedex,DHL,UPS,TNT Etc.

Support customer to designate shipping company

For more informations (the price,delivery time,moq etc)about the

ceramic plates, please contact us or email:admin@cerampart.com

CEO: Admin deng

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., 2nd Industrial Zone of Shangsha,

Chang'an town, Dongguan city, Guangdong, China 523867

Email: admin@cerampart.com

FAQ

1. Monthly Capacity: 50,000-60,000 pcs;

2. Material: OEM or as per your suggestion;

3. Lead time: about 7-20 days, pls confirm the quantities required;

4. Incoterm: FOB, CFR, CIF;

5. Delivery Cost: It is determinated by the destination port;

6. Payment Term: PayPal; T/T; L/C.

7. Shipment: by sea, by air, by courier, by post, etc.