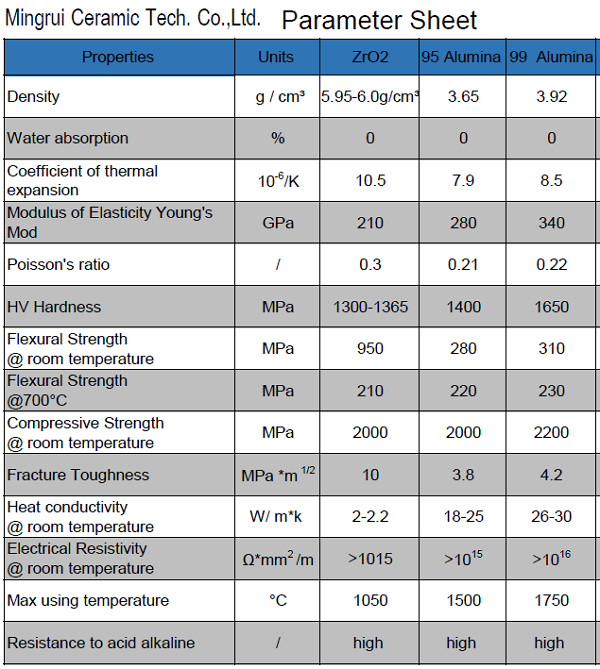

Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

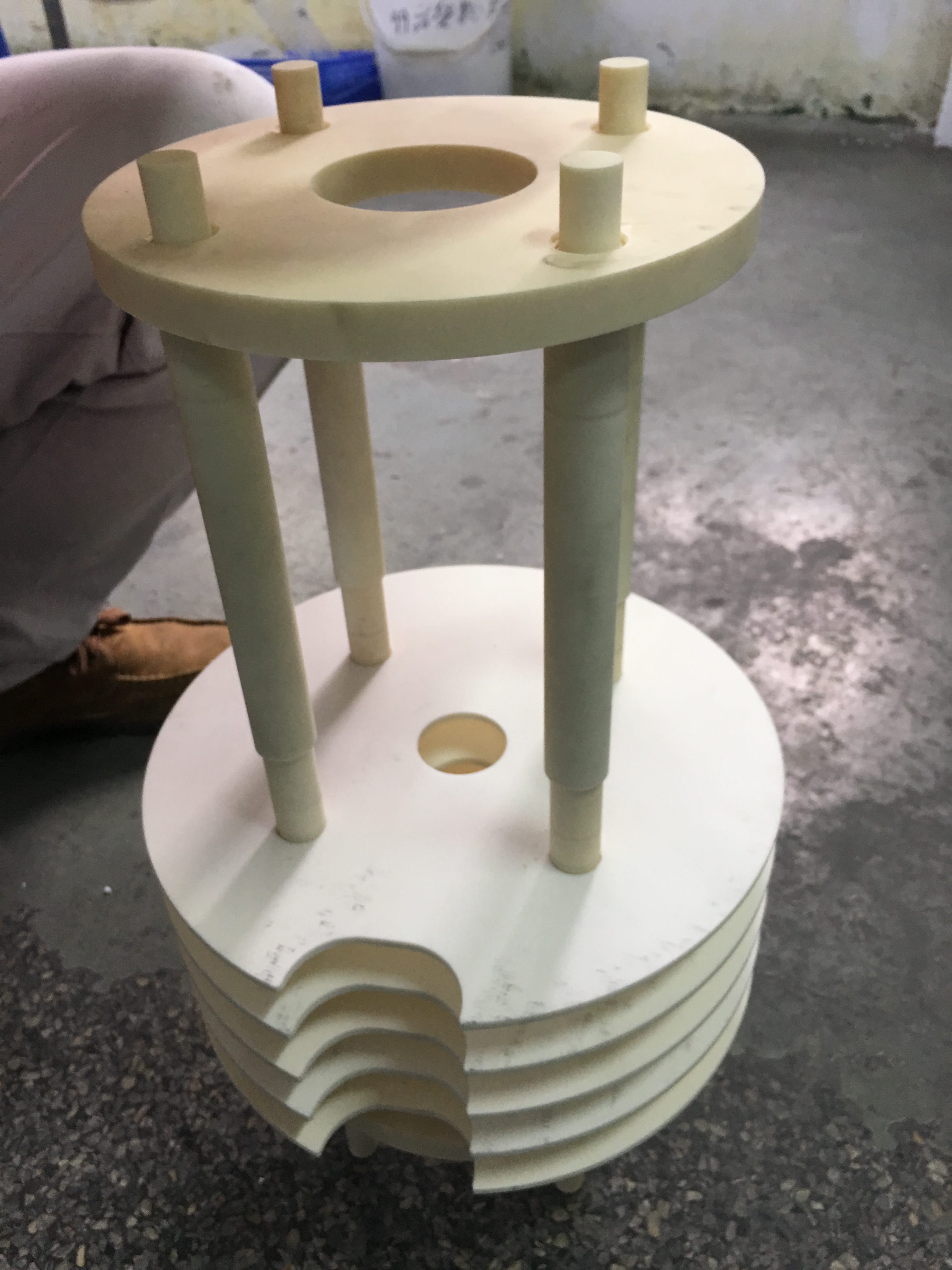

Slip Resistant Ceramic Horizontal Semiconductor Wafer Boat Semiconductor Processing Components

Key words : Horizontal Semiconductor Wafer Boat

The invention relates to a vertical rack for semiconductor wafer processing having strictly horizontally disposed arms wherein each arm has a rounded tip and a smooth (Ra < 1 < mu >m) upper surface.

The manufacture of semiconductor devices such as integrated circuits typically requires heat treating silicon wafers in the presence of reactive gases. During this process, the temperatures and gas concentrations to which the devices are exposed must be carefully controlled, as the devices often include circuitry elements less than 1 um in size which are sensitive to minute variations in the processing environment.

Horizontal Semiconductor Wafer Boat

Because a wafer processed on a vertical rack experiences less of a temperature gradient over its face (as compared to a wafer processed in a horizontal boat), semiconductor manufacturers are increasingly turning to vertical furnaces. There is, however, a drawback to vertical furnacing. The wafers disposed on a conventional vertical rack are supported at their outside edge only. As such, the areas of the wafer resting on these teeth experience higher stress than the rest of the wafer. When temperatures in the furnace exceed about 1000°C, these stresses often become significant and portions of the single crystal wafer move relative to each other along crystallographic plates in response to that stress. This phenomenon, called "slip", effectively destroys the value of the semiconductor devices located in the area of the wafer where slip has occurred.

Horizontal Semiconductor Wafer Boat Features:

| Unit | 95% Al2O3 | 99% Al2O3 | ZrO2 | GP-Si3N4 | |

| Color | - | white | ivory | white | gray |

| Density | g/cm³ | 3.70 | 3.90 | 6.04 | 3.31 |

| Water Absorption | % | 0 | 0 | 0 | 0 |

| Young's Modulus | Gpa | 280 | 350 | 205 | 295 |

| Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 |

| Flexural Strength ( at R.T. ) | Mpa | 280 | 300 | 900 | 650 |

| Compressive Strength ( at R.T. ) | Mpa | 2000 | 2500 | 2200 | 2200 |

| Thermal Conductivity ( at R.T. ) | W/(m.K) | 18-25 | 30 | 2.2 | 25 |

| Thermal Shock Resistance | ΔT(°C) | 220 | 180-200 | 280-350 | 450-650 |

| Max. Working Temperature ( at R.T. ) | °C | 1500 | 1700 | 800 | 1200 |

| Volume Resistivity ( at R.T. ) | Ω.cm | >10^15 | >10^14 | >10^12 | >10^14 |

| Dielectric Constant (1 MHz at R.T. ) | - | 9.50 | 9.80 | 26 | 8.20 |

| Dielectric Strength | kV/mm | 16 | 22 | - | 16 |

Typical Characteristics Rotor: Outside diameter: < 30,00 mm ( 1.18") Thickness: < 7,00 mm ( . 28") Groove(s) dimensions: Width > 0,051 mm ( .0002") Depth > 0,13 mm ( .0052") Length > 2,00 mm ( .0780") Stator: Outside diameter: < 30,00 mm ( 1.18") Thickness: < 7,00 mm ( . 28") Hole diameter: > 0,22 mm x 0,25 mm (.008" x .010") Surface finish, Rotor or Stator Zirconia: 0,025 m (1 in) or N1 Alumina 99,9 %: 0,05 m (2 in) or N2 Alumina 96% or 99,7%: 0,1 to 0,2 m (4 to 8 in) or N3 to N4

Advantage of Horizontal Semiconductor Wafer Boat

1. Isostatic pressed.

2. Fire resistance.

3. Superior mechnical strength.

4. High corrosion and wear resistance.

5. High Temperature Resistance.

6. Good Insulation Performance Precision.

7. Zirconia and alumina ceramic material.

They are high corrosion and wear resistance and strong impact resistance and delivers 10 times longer working life than metal plunger. They give a longer life to the sealed packing material.

Product Photos Show

Packaging and Shipping

Packed in PP bag or sponge tray, then put in standard export carton packing, or OEM packing.

Shipped by Air ( DHL, TNT, UPS, Fedex, EMS ), or Sea transportation.

Company information

Who Are We?

Mingrui is a professional factory with years OEM experience in

manufacturing industrial ceramic parts.

What Do We Do?

We produce (OEM ) strengthened structure zirconia and alumina

ceramic rod,tube, shaft, plate, sleeve, valve, plunger, bearing,

nozzle and ceramic arm, they are applicable to instruments, medical

instruments, clocks and electronic products, mills, energy and

power, machine and metals, autocar and military, spaceflight and

some other high-end fields.

All of our products with certificates, such as , CE, TUV, and so on.

Factory Show

Our Factory Welcomes Your Visiting!