Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

Heat Resistant Alumina Ceramic Gasket Washer / Disc / Shim Insulation

Key words : Alumina Ceramic Gasket / alumina nitride spacer

High-quality ceramic spacer gasket (aluminum oxide Al2O3 99.9%, 99.7% and 96% and alumina nitride ) are present for heat thermal insulation application Gasket .

Ceramic Gasket/Washer/Spacer

Ceramic washer/gasket/spacer are available in both inch and metric sizes. It helps to distribute the load of a threaded fastener. All standard sizes are in stock.

Due to their excellent characteristics in thermal, mechanical, electric and chemical properties, alumina ceramics have wide applications in the fields of ceramics, glass ceramics, industrial kilns, automobiles, metallurgy, petroleum, chemical, steel, machinery, electric power, aerospace, etc.

Features:

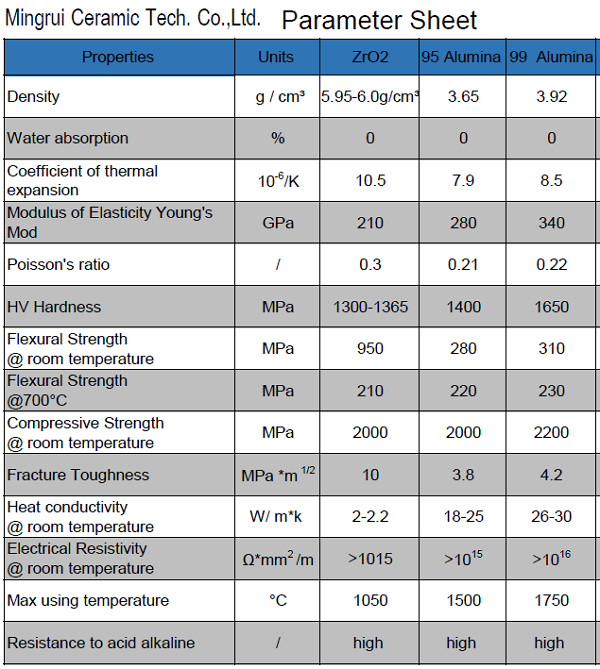

| Unit | 95% Al2O3 | 99% Al2O3 | ZrO2 | GP-Si3N4 | |

| Color | - | white | ivory | white | gray |

| Density | g/cm³ | 3.70 | 3.90 | 6.04 | 3.31 |

| Water Absorption | % | 0 | 0 | 0 | 0 |

| Young's Modulus | Gpa | 280 | 350 | 205 | 295 |

| Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 |

| Flexural Strength ( at R.T. ) | Mpa | 280 | 300 | 900 | 650 |

| Compressive Strength ( at R.T. ) | Mpa | 2000 | 2500 | 2200 | 2200 |

| Thermal Conductivity ( at R.T. ) | W/(m.K) | 18-25 | 30 | 2.2 | 25 |

| Thermal Shock Resistance | ΔT(°C) | 220 | 180-200 | 280-350 | 450-650 |

| Max. Working Temperature ( at R.T. ) | °C | 1500 | 1700 | 800 | 1200 |

| Volume Resistivity ( at R.T. ) | Ω.cm | >10^15 | >10^14 | >10^12 | >10^14 |

| Dielectric Constant (1 MHz at R.T. ) | - | 9.50 | 9.80 | 26 | 8.20 |

| Dielectric Strength | kV/mm | 16 | 22 | - | 16 |

Typical Characteristics Rotor: Outside diameter: < 30,00 mm ( 1.18") Thickness: < 7,00 mm ( . 28") Groove(s) dimensions: Width > 0,051 mm ( .0002") Depth > 0,13 mm ( .0052") Length > 2,00 mm ( .0780") Stator: Outside diameter: < 30,00 mm ( 1.18") Thickness: < 7,00 mm ( . 28") Hole diameter: > 0,22 mm x 0,25 mm (.008" x .010") Surface finish, Rotor or Stator Zirconia: 0,025 m (1 in) or N1 Alumina 99,9 %: 0,05 m (2 in) or N2 Alumina 96% or 99,7%: 0,1 to 0,2 m (4 to 8 in) or N3 to N4

Advantage of alumina ceramic spacer gasket / alumina nitride spacer

1. Isostatic pressed.

2. Fire resistance.

3. Superior mechnical strength.

4. High corrosion and wear resistance.

5. High Temperature Resistance.

6. Good Insulation Performance Precision.

7. Zirconia and alumina ceramic material.

They are high corrosion and wear resistance and strong impact resistance and delivers 10 times longer working life than metal plunger. They give a longer life to the sealed packing material.

Product Description

Performance For Industrial Ceramic | |||

Item | Character | Unit | Zirconia |

Physical Characteristics | Heat resistance | 0C | 2000 |

Bulk density | g/cm3 | 6.00 | |

Water absorption | % | 0 | |

| Flexural strength | Mpa | 950 |

Hardness vickers | Gpa | 89 | |

Elastic modulus | Gpa | 200 | |

Poisson’s ratio | 0.31 | ||

Thermal Characteristics | Linear expansion coefficient | (20-5000C)10-6/0C | 10 |

Thermal conductivity | w/(m.k) | 2.5 | |

Specific Heat | *10-3J/(kg*K) | 0.5 | |

Electrical Characteristics | Dielectric constant (1MHZ) | - | N.A. |

Dielectric loss angle | *10-4 | N.A. | |

Dielectric

strength | *106V/m | N.A. | |

Product Photos Show

Packaging and Shipping

Packed in PP bag or sponge tray, then put in standard export carton packing, or OEM packing.

Shipped by Air ( DHL, TNT, UPS, Fedex, EMS ), or Sea transportation.

Company information

Who Are We?

Mingrui is a professional factory with years OEM experience in

manufacturing industrial ceramic parts.

What Do We Do?

We produce (OEM ) strengthened structure zirconia and alumina

ceramic rod,tube, shaft, plate, sleeve, valve, plunger, bearing,

nozzle and ceramic arm, they are applicable to instruments, medical

instruments, clocks and electronic products, mills, energy and

power, machine and metals, autocar and military, spaceflight and

some other high-end fields.

All of our products with certificates, such as , CE, TUV, and so on.

Factory Show

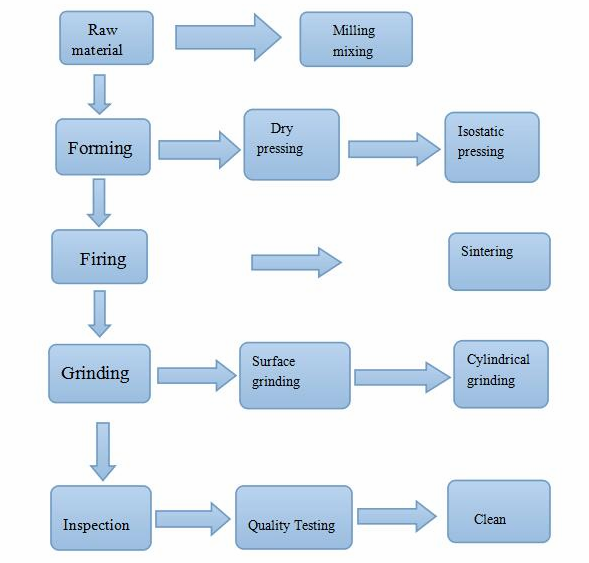

Production Process Show

Certificates Show

Our Factory Welcomes Your Visiting!