Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

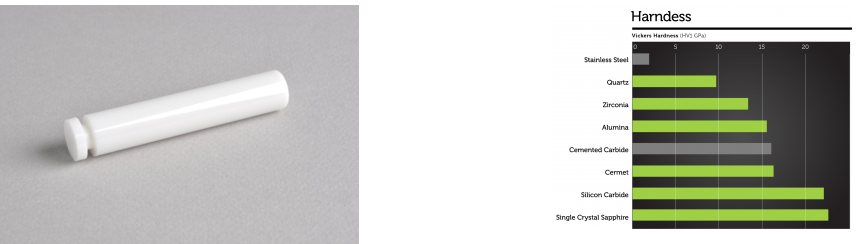

Fine Polished Precision 99% Alumina Ceramic Plunger For Pump , Alumina Ceramic Parts

Ceramic plungers

Ceramic plungers work exceptionally well for most saltwater, chemical, and metering applications. IEQ specially-formulated grades of ceramic allow for a standard 8 RMS surface finish dramatically extending packing life.

Made of durable stainless steel, IEQ adapters successfully resist corrosion. We use a proprietary process to bond the ceramic body to the stainless steel adapter for extremely reliable performance in the field.

IEQ ceramic plungers are available in the hollow ceramic design, as well as the solid ceramic design.

When corrosion and abrasion resistance are required and extended packing life is needed, ceramic plungers are unmatched in performance. However, ceramic plungers are not optimal for every application. For example, we do not recommend their use in pumping hazardous materials. Contact one of our specialists for more information.

Cat Pumps part 43232 Ceramic Plunger for the CAT 56, 56G, 58, 58G, 59, 59G, 60, 60G 7 Frame Series Pumps. Plunger Dimensions: 18mm x 77mm/Long. Each pump uses 3 plungers. This is a Mingrui certified used part. These parts have been thoroughly inspected and except for color they are equivalent as new.

Ceramic plungers work exceptionally well in wear-resistance, high temperature, saltwater, chemical, and metering applications. Ortech Alumina Oxide, Zirconia Oxide, Silicon Nitride and Silicon Carbide ceramic material allow a standard 8 RMS surface finish – dramatically extending packing life.

Made of durable stainless steel, Ortech adapters successfully resist corrosion. We use a proprietary process to bond the ceramic body to the stainless steel adapter for extremely reliable performance in the field. Ortech ceramic plungers are available in the hollow ceramic design as well as the solid ceramic design. When corrosion and abrasion resistance are required and extended packing life is needed, ceramic plungers are unequaled in performance. However, ceramic plungers are not optimal for every application. Contact one of our specialists for more information.

Alumina Ceramic plunger

At the present time the special position in area of equipment for dwelling houses and production facilities is occupied by electric heating devices which key elements are, surely, tubular electric heaters (TEHs). Ceramic bushings, being mounted at the ends of a tubular heater, provide its electrical insulation and air-tightness. Thus, we manufacture the products which can be found almost anywhere – in electric boilers, autoclaves, washing mashines, water heaters, electric hot plates, etc. Such a broad scope of usage results in a wide diversity of ceramic bushings’ forms and sizes, and just some of them are shown here at the following photos:

Properties of the material alumina Plunger

alumina ( Al2O3) is an extremely refractory material. It possesses excellent chemical inertness and corrosion resistance at temperatures well above the melting point of alumina. Innovacera Zirconia is fully stabilized in the cubic crystal structure to avoid cracking and mechanical weakening during thermal cycling. In addition to its high temperature capability, Zirconia offers low thermal conductivity and is electrically conductive above 800ºC. Also has the unique ability to allow oxygen ions to move freely through the crystal structure above 600ºC.

Properties | Units | Alumina(Al2O3) | |||||

Al2O3 92% | Al2O3 95% | Al2O3 99% | Al2O3 99.5% | ||||

Mechanical | Density | g/cm3 | 3.6 | 3.7 | 3.9 | 3.9 | |

Color | -- | White | White | Ivory | Ivory | ||

Water Absorption | % | 0 | 0 | 0 | 0 | ||

Vickers Hardness | Gpa | 11 | 11.5 | 13 | 14 | ||

Flexural Strength (20°C) | Mpa | 345 | 358 | 380 | 380 | ||

Compressive Strength (20°C) | Mpa | 2200 | 2300 | 3000 | 3000 | ||

Thermal | Thermal Conductivity (20°C) | W/m.K | 16.7 | 24.8 | 25~35 | 25~35 | |

Thermal Shock Resistance (20°C) | ΔT(C) | 250 | 250 | 200 | 200 | ||

Maximum Use Temperature | °C | 1500 | 1600 | 1700 | 1700 | ||

Electrical | Volume Resistivity (25°C) | Ω.cm | >1014 | >1014 | >1014 | >1014 | |

Characteristic: Resistance to strong acid, strong alkali, salt and gas of deleterious, long life, high hardness, resistance to wear, especially resistance to hydrofluoric acid.

Ceramic parts are more resistant to heat meaning more reliable, better performing, longer lasting, and they are electric insulation can be used in many fields.

Zirconia sleeves are widely used in electrical industry, ceramic industry, oil industry, food industry, medical industry, chemical industry etc. to replace metal sleeves.

If you are interested in this product or just want to know more about ceramic products, never hesitate to contact us.

We are looking forward to developing business relationships with you.

Alumina has a wide application due to its versatility and low material cost. Alumina possesses a high melting point, strong hardness, and good chemical stability, making it a good material to withstand high temperature and chemical corrosion. zirconia Plates and Disks are available in different dimensions and thicknesses. Call for custom shapes and sizes.

Refractory alumina ceramic substrate/ceramic plate is our main product.Misson can supply high quality alumina plates with competitive prices.

Very small and very large sized plates can be made.

Fine grinding can made tight tolerance.

High temperature and abrasive resistance is good

Product features :

Applicable to make ceramic wrist watch, watch ctrap, bracelet, ring and necklace etc. With the property of abrasion resistance, invariant color, elegance and shining, ceramics are the ideal decorative material for watch and jewelry industry. All the ceramics can be customized.

1. High hardness.

2. High heat resistance : Alumina ceramic has excellent thermal stability,which means that it is

widely used in areas where resistance to high temperatures is essential.

3. Good wear resistance : Alumina ceramic is the material of choice for alumina wear parts.

4. High electrical resistivity : Alumina is an electrically insulating material.

5. High corrosion resistance : It is insoluble in water and only slightly soluble in strong acid and

alkaline solutions. Good chemical stability of alumina leads to high corrosion resistance.

Quality assurance:

Alumina ceramic is the most mature of the engineering ceramics, offering excellent electrical insulation properties together with high hardness and good wear resistance,but relatively low strength and fracture toughness.Alumina ceramics are generally white but may also be pink or ivory.The color is derived from either the sintering additives or impurities in the raw materials.

| Properties | Units | 95 Alumina | 99 Alumina | ZrO2 |

| Density | g / cm³ | 3.65 | 3.92 | 5.95-6.0g/cm³ |

| Water absorption | % | 0 | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 | 210 |

| Poisson's ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness HV | MPa | 1400 | 1650 | 1300-1365 |

| Flexural Strength @ room temperature | MPa | 280 | 310 | 950 |

| Flexural Strength @700°C | MPa | 220 | 230 | 210 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 | 2000 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 | 10 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 | 2-2.2 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 | >1015 |

| Max use temperature | °C | 1500 | 1750 | 1050 |

| Resistance to acid alkaline | / | high | high | high |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV/mm | 16 | 22 | / |

| Thermol Shock Resistance | T ( °C ) | 220 | 180-200 | 280-350 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 | 252 |

We ( Dongguan Mingrui Ceramic Technology Co., Ltd ) are a

professional manufacturer specialized

in R&D, manufacturing and selling customized all kinds of high

precision zirconia and alumina ceramic parts . Our main products

include ceramic rod , ceramic tube, ceramic plunger, ceramic valve,

ceramic plate, ceramic shaft and bearing , ceramic nozzle etc ,

which are mainly used in industrial fields of Machinery,

Petrochemical oil and gas, Valves, Automotive, Food Processing,

Fluid Handling, Process Control, Thermal Processing, Aerospace,

Defense, Eletronic and Electrical, Textile, Mechanical,

Engineering, Mineral Processing, etc.

We have a full service include mold design and development ,

ceramic forming , precision machining

and precision detection technology. We have achieved great successes in particular requirements

which is based on cooperating with Tsinghua University and getting rich experience by our professional technical engineer teams . Our factory have an unique technical called mirror polishing which improve

our products more smooth , bright than other competitors.

1. What kind of industry ceramics do you have ?

We specialized in 95% 97% 99% alumina ceramic and zirconia ceramic parts .

2. What kind of molding method do can you supply ?

Dry Pressing , isostatic pressing , grouting , hot-chamber die casting , tape casting , injection molding, etc, injection molding and isostatic molding is the most commonly used.

3.What stabilizer do you use when processing ?

Yttria stabilizer is the most commonly used in our industrial ceramic parts.

4.Can you produce free samples for me ?

Yes usually , we can produce free samples for you but it is up to the product complexity .

5.What terms can you accept for payment ?

T/T, L/C , Western union , Money Gram and Paypal is welcome , but paypal and western union only for small -sum payment.