Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

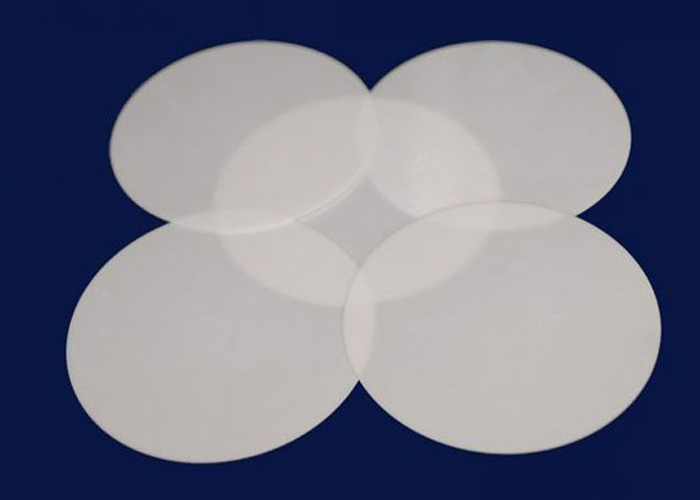

Untra Thin Zirconia Ceramic Disc / Plate Diameter 22mm Thickness

0.2mm

Zirconia Machining and Grinding

| While the same design features common to alumina ceramics; blind

holes, threads etc. are easily produced in Zirconia the grinding

time required is about fifty percent more. The post-grinding

surface finish is significantly better than a comparable feature in

most aluminas. Zirconia is much more dense, finer grain and stronger than alumina ceramic. The combination of these physical properties make Zirconia an excellent material choice when strength and wear resistance are required. Zirconium Oxide ceramic has unique physical and chemical properties as you will see in the properties data sheet below. If we can be of assitance please contact us, we will be pleased to hear from you. |

|

The hot isostatic pressure process improves the physical structure and capability of ceramics by extracting impurities from the material via application of an inert gas. Once the parts are dense enough from the gas exposure, (usually processed in a chamber) they are suitable for medical applications, though all products are inspected before they are supplied to medical resources.

Injection molding is a process that involves producing parts (usually metals and ceramics) that are intricate in design, such as dental brackets. This process is executed by molding machines, and numerous devices are capable of being produced in a short time-frame. Injection molding is considered a good alternative to previous processing, as standard stamping and machining techniques of the past took more time and expense.

Alumina ceramic screws/nuts and bolts are used in applications where conventional metal or plastic components will not work. Ceramic nuts and bolts are strong, rigid, non-magnetic and operate at high temperature and in corrosive environments.

Alumina Properties sheet :

| Items | Unit | 95% Al2O3 | 99.5% Al2O3 |

| Density | g/cm3 | 3.7 | 3.9 |

| Flexural strength | MPa | 313 | 340 |

| Compressive strength | MPa | 3400 | 3600 |

| Modulus of elasticity | GPa | 350 | 380 |

| Impact resistance | MPa·m1/2 | 4 | 5.1 |

| Weibull modulus | m | 10 | 10 |

| Vickers hardness | HV0.5 | 1800 | 1900 |

| Thermal conductivity | W/mk | 24 | 27 |

| Highest application temperature | °C | 1600 | 1750 |

| Volume resistivity at 20°C | Ω.cm20 | >1014 | >1014 |

| Dielectric strength | kV/mm | 20 | 25 |

| Thermal expansion | X10-6/K | 5.0-8.3 | 5.4-8.3 |

Product features :

High strength and no harm to healthy

2. High heat resistance : Alumina ceramic has excellent thermal

stability,which means that it is

widely used in areas where resistance to high

temperatures is essential.

3. Good wear resistance : Alumina ceramic is the material of choice

for alumina wear parts.

4. High Strength not easy to break

5. Glazed and polished surface very nice looking

We ( Dongguan Mingrui Ceramic Technology Co., Ltd ) are a

professional manufacturer specialized

in R&D, manufacturing and selling customized all kinds of high

precision zirconia and alumina ceramic parts . Our main products

include ceramic rod , ceramic tube, ceramic plunger, ceramic valve,

ceramic plate, ceramic shaft and bearing , ceramic nozzle etc ,

which are mainly used in industrial fields of Machinery,

Petrochemical oil and gas, Valves, Automotive, Food Processing,

Fluid Handling, Process Control, Thermal Processing, Aerospace,

Defense, Eletronic and Electrical, Textile, Mechanical,

Engineering, Mineral Processing, etc.

We have a full service include mold design and development ,

ceramic forming , precision machining

and precision detection technology. We have achieved great

successes in particular requirements

which is based on cooperating with Tsinghua University and getting

rich experience by our professional technical engineer teams . Our

factory have an unique technical called mirror polishing which

improve

our products more smooth , bright than other competitors.

1. What kind of industry ceramics do you have ?

We specialized in 95% 97% 99% alumina ceramic and zirconia ceramic

parts .

2. What kind of molding method do can you supply ?

Dry Pressing , isostatic pressing , grouting , hot-chamber die

casting , tape casting , injection molding, etc, injection

molding and isostatic molding is the most commonly used.

3.What stabilizer do you use when processing ?

Yttria stabilizer is the most commonly used in our industrial

ceramic parts.

4.Can you produce free samples for me ?

Yes usually , we can produce free samples for you but it is

up to the product complexity .

5.What terms can you accept for payment ?

T/T, L/C , Western union , Money Gram and Paypal is welcome , but

paypal and western union only for small -sum payment.

Our equipment :