Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

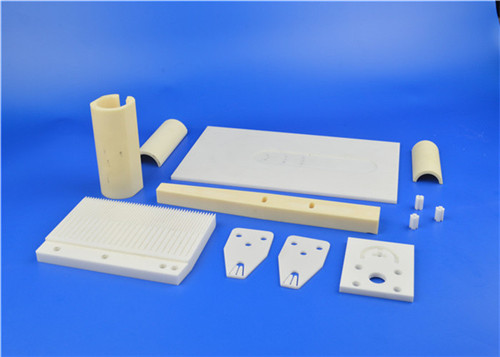

Half Round Alumina Ceramic Parts / Alumina Ceramic Blocks with Holes

| Product Name | Half Round Alumina Ceramic Parts / Alumina Ceramic Blocks with Holes |

| Material | Alumina Ceramic |

| Color | white or black or customed |

| Custom | normally |

| Surface | smooth , glossy |

| Machinable | yes |

| precision | high |

| Used | ceramic substrates |

Alumina Ceramic Blocks consist of pure copper bonded to a ceramic substrate such as Al2O3 (Alumina), AlN (Aluminum Nitride), HPS (ZrO2 doped) or silicon based Si3N4 (Silicon Nitride).

Mingrui provides two technologies to attach the substrate with the copper. DBC (direct bond copper) – a high temperature melting and diffusion process where the pure copper is bonded onto the ceramic and AMB (active metal brazing) – a high temperature process where the pure copper is brazed onto the ceramic substrate.

The high heat conductivity as well as the high heat capacity and thermal spreading of the thick copper cladding makes curamik substrates indispensable to power electronics. The mechanical stress on silicon chips mounted directly on the substrate (Chip on Board) is very low, since the coefficient of thermal expansion (CTE) of the ceramic substrate is better matched to the CTE of silicon compared to substrates using a metal or a plastic basis

Alumina Ceramic Blocks are produced in a master card format of 5“x7“ and 5,5“x7,5“. The individual parts can be left in the master card format to support more efficient assembly and mounting of components before being separated into individual pieces. We also offer single pieces for single piece assembly.

Alumina Ceramic Blocks Advantages:

More photos of Alumina Ceramic Blocks :

Ceramic adapter plate,Ceramic centering pin,Ceramic connectors,Ceramic spinner,Ceramic roller

Ceramic blade,Ceramic brackets,Ceramic disc,Ceramic insulator,Ceramic rod,ceramic atomizer

ceramic fuse pin,ceramic nozzle,ceramic ferrule,ceramic necklace,ceramic ornament,alumina ceramic plate, ceramic cylinder, ceramic guide, ceramic pin, ceramic bushing, ceramic brick,ceramic injection molding,ceramic bushings,ceramic smoking pipe, ceramic spacer,ceramic piston pump,ceramic part

ceramic heating element vaporizer e cigarette, al2o3 ceramic, ceramic donut atomizer, alumina ceramic disc, alumina ceramic sheet , ceramic alumina , ceramic pressure sensor , ceramic sheet,

ceramic washer, zirconia ceramic plate, ceramic insert, white ceramic ring, ceramic shaft

ceramic pump, ceramic piston, ceramic nail, ceramic insulators, ceramic rod 3mm , ceramic dowel pin

ceramic pin gage , alumina ceramic parts , ceramic burr , ceramic proppant , ceramic needle

ceramic grinder, alumina ceramic rod , alumina ceramic ring, ceramic conical burr , ceramic heater rod

ceramic gear , machinable ceramic, ceramic arms , white ceramic ornaments , sustained high temperature on ceramics

Mingrui offers you a wide range of production facilities like extrusion, injection moulding, pressing and casting. Depending on product geometry and quantities, we will choose the suitable technique for your products.For the final finishing of the parts we use CNC machining centres, equipped with diamond tools in order to meet high accuracies.

Our aim is to offer the ideal solution for any application. Our engineers therefore offer custom solutions that range beyond our existing product portfolio. With our well-equipped industrial development facilities, we produce innovations that can be rapidly commercially exploited.