Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

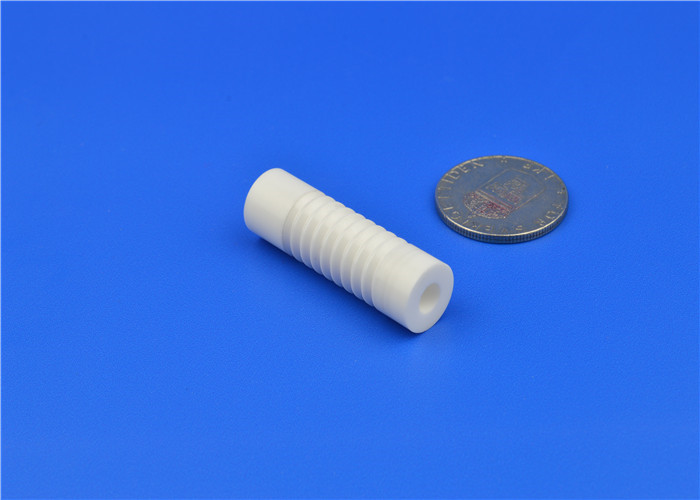

High Precision Yttria Stabilized Zirconia Tube / Bushing / Sleeve / Insulator

Tag Key words : Yttria Stabilized Zirconia Tube / Bushing / Sleeve / Insulator

Yttria Stabilized Zirconia Tube has very high hardness, very high stiffness, very good corrosion resistance to chemicals at high temperature, and very high refractoriness or use temperature. They may be used for a variety of electrical, mechanical, and thermal applications. They may be used as setter plates for firing parts in a kiln. The may be used for high temperature furnaces and as high temperature refractory turntables. Yttria Stabilized Zirconia Tube / Bushing / Sleeve / Insulator may also be used for jewelry or for applications requiring high wear or abrasion resistance. Your imagination is the only limiting factor in the spectrum of possible applications for this component. Be sure to view all photos as they are an integral component of the item description.

Specific Gravity or Density: 3.9 g/cm3

Water Absorption or Porosity: 0%

Fusion Temperature or Melting Temperature: 2000 °C or 3632 °F

Maximum Working Temperature: 1800 °C or 2800 °F

Thermal Conductivity: 25 W/m* K

Specific Heat: 0.9 J/g*K

Expansion Coefficient or CTE: 7.5 x 10 E-6 inches/°C

Electrical Resistivity at 20 C: 10 E14 Ohm*cm

Electrical resistance at 600 C: 10 E8 Ohm*cm

Modulus of Elasticity: 44 x 10 E6 p.s.i. or 350 GPa.

| Product Name | High Precision Yttria Stabilized Zirconia Tube / Bushing / Sleeve / Insulator |

| Material | zirconia |

| Color | White, Black , Blue , Yellow |

| OD | 0.2mm - 200mm, And According to drawings |

| Length | 5mm - 400mm, And According to drawings |

| Surface Roughness | Ra0.05 |

| Torlerance | +/- 0.001mm |

| Lead time: | 15 days |

| Max. working temperature | 1500 -2800 °C |

| Samples | Avaliable |

| Shipping: | Air Express (DHL/UPS/TNT/ FedEx) or Ocean Shipping |

Ceramic adapter plate,Ceramic centering pin,Ceramic connectors,Ceramic spinner,Ceramic roller

Ceramic blade,Ceramic brackets,Ceramic disc,Ceramic insulator,Ceramic rod,ceramic atomizer

ceramic fuse pin,ceramic nozzle,ceramic ferrule,ceramic necklace,ceramic ornament,alumina ceramic plate, ceramic cylinder, ceramic guide, ceramic pin, ceramic bushing, ceramic brick,ceramic injection molding,ceramic bushings,ceramic smoking pipe, ceramic spacer,ceramic piston pump,ceramic part

ceramic heating element vaporizer e cigarette, al2o3 ceramic, ceramic donut atomizer, alumina ceramic disc, alumina ceramic sheet , ceramic alumina , ceramic pressure sensor , ceramic sheet,

ceramic washer, zirconia ceramic plate, ceramic insert, white ceramic ring, ceramic shaft

ceramic pump, ceramic piston, ceramic nail, ceramic insulators, ceramic rod 3mm , ceramic dowel pin

ceramic pin gage , alumina ceramic parts , ceramic burr , ceramic proppant , ceramic needle

ceramic grinder, alumina ceramic rod , alumina ceramic ring, ceramic conical burr , ceramic heater rod

ceramic gear , machinable ceramic, ceramic arms , white ceramic ornaments , sustained high temperature on ceramics

Mingrui offers you a wide range of production facilities like extrusion, injection moulding, pressing and casting. Depending on product geometry and quantities, we will choose the suitable technique for your products.For the final finishing of the parts we use CNC machining centres, equipped with diamond tools in order to meet high accuracies.

Our aim is to offer the ideal solution for any application. Our engineers therefore offer custom solutions that range beyond our existing product portfolio. With our well-equipped industrial development facilities, we produce innovations that can be rapidly commercially exploited.

Properties Sheet of zirconia and alumina :

| Properties | Units | 95 Alumina | 99 Alumina | ZrO2 |

| Density | g / cm³ | 3.65 | 3.92 | 5.95-6.0g/cm³ |

| Water absorption | % | 0 | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 | 210 |

| Poisson's ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness HV | MPa | 1400 | 1650 | 1300-1365 |

| Flexural Strength @ room temperature | MPa | 280 | 310 | 950 |

| Flexural Strength @700°C | MPa | 220 | 230 | 210 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 | 2000 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 | 10 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 | 2-2.2 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 | >1015 |

| Max use temperature | °C | 1500 | 1750 | 1050 |

| Resistance to acid alkaline | / | high | high | high |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV/mm | 16 | 22 | / |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 180-200 | 280-350 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 | 252 |