Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

Advanced Precsion Ceramic Components Zirconia ceramic Injection Molding Parts

In the Ceramic Injection Molding (CIM) sector, Mingrui is one of the pioneers. we have been working with this innovative technology. It creates a perfect symbiosis between the process of ‘injection molding technology’ and the materials known as ‘high-performance ceramics’. The familiar mold design options for the processing of plastics, e.g. internal and external threads, internal recesses and ribs are all applicable to ceramic components through the use of injection molding technology. As well as the qualitative benefits of technical ceramics as materials, this also means that the injection molded part can, in many instances, also benefit in terms of economic viability, i.e. cost.

Ceramic injection moulding

Ceramic injection molding parts

Injection ceramic molding

injection molding ceramics

injection molded ceramic

small injection molding ceramic parts

Zirconia ceramic is the most mature of the engineering ceramics, offering excellent electrical

insulation properties together with high hardness and good wear resistance,but relatively low

strength and fracture toughness.Alumina ceramics are generally white but may also be pink or

ivory.The color is derived from either the sintering additives or impurities in the raw materials.

1. High hardness.

2. High heat resistance : Alumina ceramic has excellent thermal stability,which means that it is

widely used in areas where resistance to high temperatures is essential.

3. Good wear resistance : Alumina ceramic is the material of choice for alumina wear parts.

4. High electrical resistivity : Alumina is an electrically insulating material.

5. High corrosion resistance : It is insoluble in water and only slightly soluble in strong acid and

alkaline solutions. Good chemical stability of alumina leads to high corrosion resistance.

| General Characteristics of Materials: | ||||

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium | | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

| Oxidation Resistance | Medium to High | low | low | / |

| Machinability | Medium | low | Medium | / |

| Product Name | Advanced Precsion Ceramic Components Zirconia ceramic Injection Molding Parts |

| Material | Alumina Ceramic or zirconia ceramic |

| Color | white or black or customed |

| Standard | according the request of customer |

| Grade | first class |

| Brade | Rock |

| Thread | coarse, fine |

| Used | Advanced Precsion Ceramic Components Zirconia ceramic Injection Molding Parts |

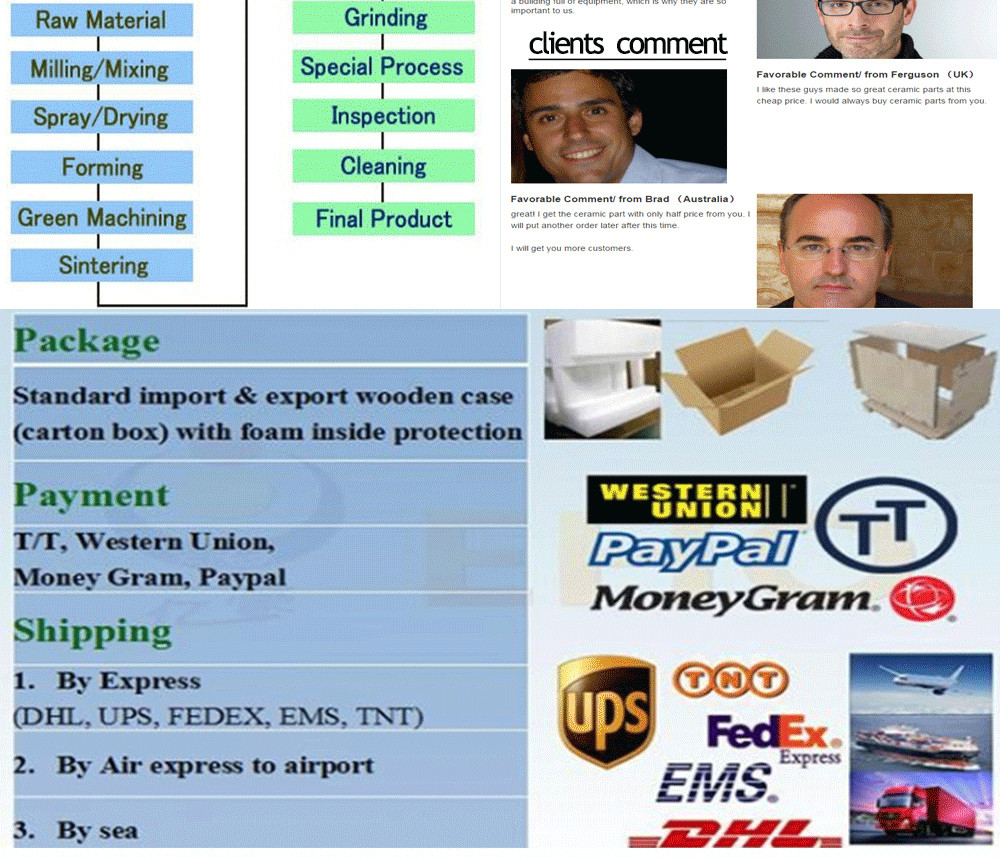

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance before shippment.

If you have any other question, pls feel free to contact us .