Dongguan Ming Rui Ceramic Technology Co.,ltd |

|

Insulator Alumina Ceramic Parts Photovoltaic Processing Equipment

Advantages:

1). Excellent insulation, security, long working life.

2). Excellent high temperature resistance

3). Low thermal expansion coefficient

Other services:

Greener Manufacturing

Custom/Standard Shapes

Ceramic precision manufacturing

Fine machining

Ceramic machinable parts

Product Description

Precision Ceramics has years of experience designing and developing technical ceramic solutions for a wide variety of applications and industries. Insulator Alumina Ceramic Parts Photovoltaic Processing Equipment. We offer this expertise to all of our customers to ensure the best design and materials are chosen for their specific application and needs. Insulator Alumina Ceramic Parts Photovoltaic Processing Equipment, Typically, our custom technical ceramic components and parts we supply are used for one of three main reasons:

Insulator Alumina Ceramic Parts Photovoltaic Processing Equipment

High temperature ceramics – crucibles, nozzles, lasers,

furnace/kiln fixtures

Insulator Alumina Ceramic Parts Photovoltaic Processing Equipment

Wear and corrosion resistant ceramics – plates, housings, gages,

caps/lids

Insulator Alumina Ceramic Parts Photovoltaic Processing Equipment

Electrical insulation ceramics – contact blocks, standoffs,

fasteners, spacers

Insulator Alumina Ceramic Parts Photovoltaic Processing Equipment

Precision Ceramics is one of the world’s premiere technical ceramic

suppliers – contact us to see what technical ceramics we can create

for you.

Insulator Alumina Ceramic Parts Photovoltaic Processing Equipment

| General Characteristics of Materials: | ||||

| Characteristic | Ceramics | Metals | Polymers | Refractory |

| Density | Low to High | Low to High | Low | Low to Medium |

| Hardness | High | Medium | low | Medium |

| Toughness | low | High | Medium | low |

| Wear Resistance | High | Medium | low | Medium |

| Tensile Strength | Low to Medium |

High | low | low |

| Compressive Strength | High | Medium to High | low to Medium | High |

| Young’s Modulus | Medium to High | Low to High | Low | Medium |

| Dimensional Stability | High | low to Medium | low | / |

| Thermal Expansion | Low to Medium | Medium to High | High | low |

| ThermalConductivity | Medium | Medium to High | Low | Medium |

| Thermal Shock | Low | Medium to High | High | low to Medium |

| Electrical Resistance | High | low | High | / |

| Chemical Resistance | High | low to Medium | Medium | / |

| Oxidation Resistance | Medium to High | low | low | / |

| Machinability | Medium | low | Medium | / |

| Product Name | Insulator Alumina Ceramic Parts Photovoltaic Processing Equipment |

| Material | Alumina Ceramic or zirconia ceramic |

| Color | white or black or customed |

| Standard | according the request of customer |

| Grade | first class |

| Brade | Rock |

| Thread | coarse, fine |

| Used | Insulator Alumina Ceramic Parts Photovoltaic Processing Equipment |

Industrial Ceramic Intriduction

Aluminium Oxide, Al2O3 is the most widely applied and cost

effective technical ceramic material. It offers a combination of

superior mechanical strength and electrical properties, wear

resistance and corrosion resistance. The maximum working

temperature is up to 1700 °C with relatively high thermal

conductivity. It is also an electrically insulating material with a

high electrical resistivity. The good corrosion resistance makes it

insoluble in water and slightly soluble in strong acid and alkaline

solution.

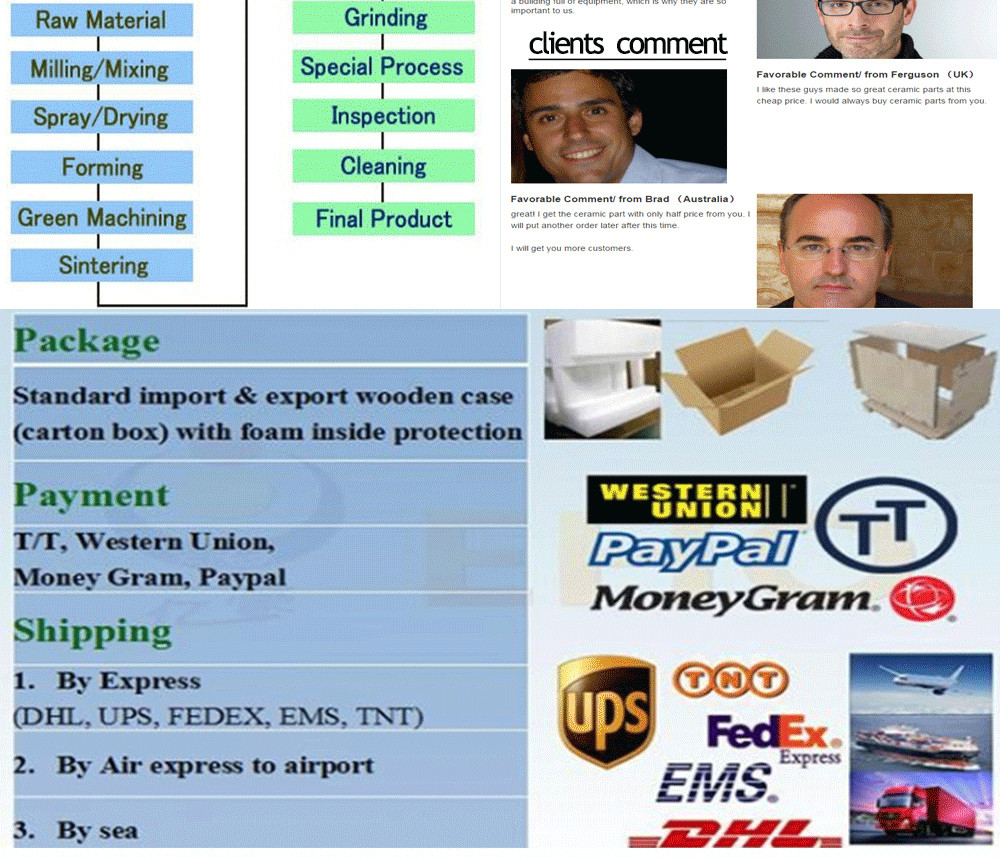

1. Are you trade company or manufactuer?

We are China professional manufacturer of customizing various thermal interface materials, such as silicone gap thermal pad, thermal insulator material, Silicone Rubber sheet,thermal graphite Sheet etc with more than 6 years experience.

2. Why price is so low?

You are ordering from factory bottom price!

3. How can you guarantee the quality?

With advanced production machine and testing equipment,we ensure 100% quality inspection before shipping.

4.What's the leadtime?

Sample order costs 1-3 working days,and 7-15 working days for mass production.

5. Can i take sample?

Yes,we are honored to provide you sample.

6.What payment term is available?

We can accept TT,Western Union,LC.