Zhengzhou Sanhui Refractory Metal Co., Ltd. |

|

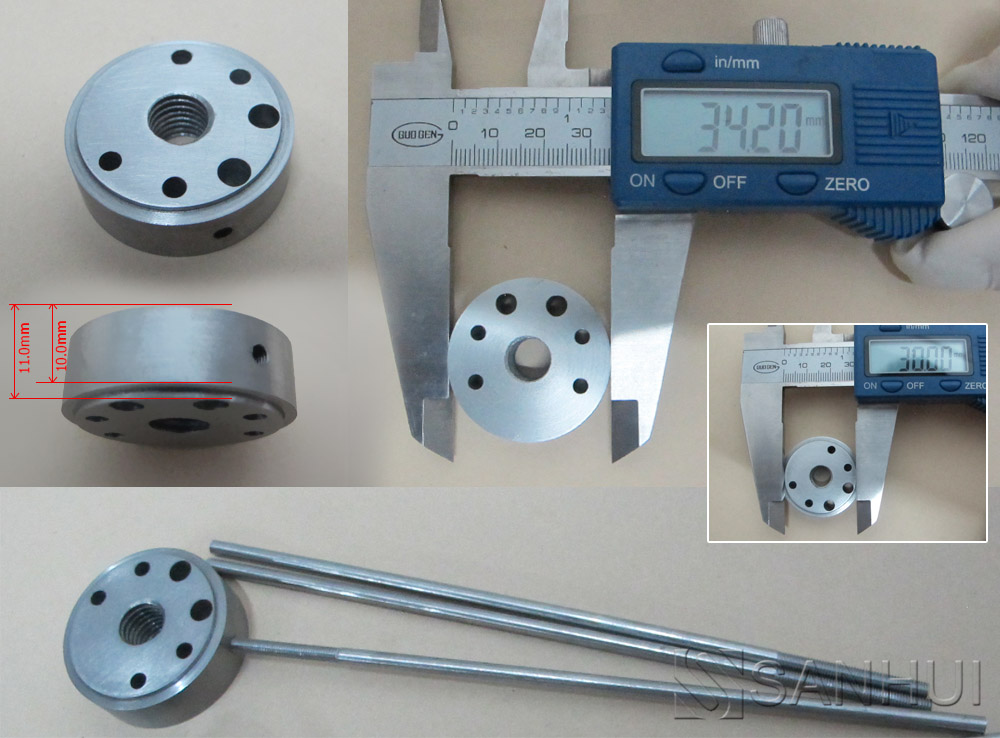

99.95% or more Purity Molybdenum Parts as Collimator

Quick Details

Model Number: Molybdenum machining part

Application: high temperature, collimator

Process: lathe CNC

Dimensions: as per drawing

Chemical Composition: Mo,99.95% or more

Specification:

Customized Precision Molybdenum Machining Fittings Applications

Zhengzhou Sanhui Co., Ltd. which has been dealing in W and Mo deep

processing, R&D for 31 years. Our W and Mo products are widely

used in semiconductor, new display industries, clean energy,

weapons and equipment, nuclear industry, aerospace, building

materials, industrial furnaces and other industries. Molybdenum machining fittings can be applied in high temperature

furnace and for making thin film products.

Our company will make customized parts with specifications,

dimensions according to clients' requirements.

Detection ability

We are able to test density, hardness, surface roughness,

grain size, tensile strength and other parameters of molybdenum

parts. With special equipments we can precisely get the overall

density of the large crucibles, which may reflect the real

performance of the crucible. The possible hidden factory of

crucible such as porosity, slag, cracks and other injuries are

doubly strictly inspected with eddy current and ultrasonic

equipments by us to ensure the quality of our sintered

The highest using temperature should not more than 1750ºC