Shenzhen Factory OEM Precision Lathe Turning Custom 3/4/5 Axis

Milling CNC Machining Large Parts

Features of Shenzhen Factory OEM Precision Lathe Turning Custom

3/4/5 Axis Milling CNC Machining Large Parts

- Outstanding EMI/RFI shielding properties

- High strength and hardness

- High thermal conductivity

- Good finishing characteristics

- High electrical conductivity

- Good corrosion resistance

Application of Shenzhen Factory OEM Precision Lathe Turning Custom

3/4/5 Axis Milling CNC Machining Large Parts

- Medical EquipmentsMechanical Parts

- Auto Components Hardware Parts Auto Parts

- Ship Accessories

- Electrical Equipment

- Industrial Equipment

- Mechanical Equipment

- Communication Equipment

Advantages of Yixin Precision Metal and Plastic Ltd

- Value-added services: A trusted partner who can help you purchase a variety of other

legal items, including a variety of special products.

- On Time Delivery: Sufficient production capacity and strong project management.

- One-Step Service: offer from design, machining, surface treatment to finally

assembly.

- Competitive Price: we are original manufacturer; low operating cost and innovative

ideas enable to offer very competitive cost.

- Good Service: Good service runs throughout the whole process from

inquiry/quotation, sampling, production, inspection, packaging to

delivery and after sale.

- Quick Response: your inquiry will be replied in 24 hours, sales are more than 20

years of engineer background, react fast and give strong support.

- Production Capacity: 105sets Swiss Machining Lathes and 100sets 3/4/5 Axis CNC

machining centers with 500,000pcs monthly of sufficient production

capacity enable to meet large demand.

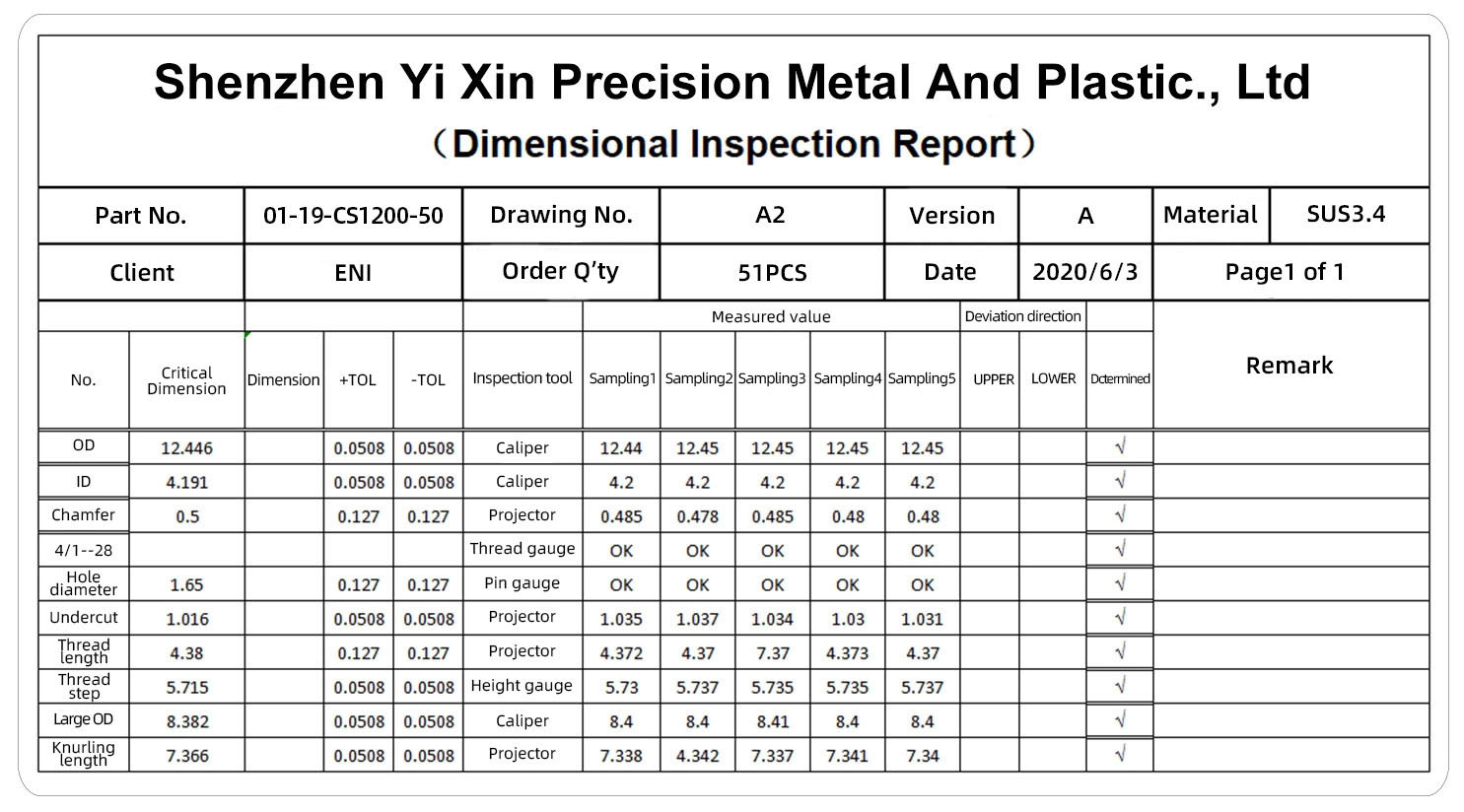

- Quality Guarantee: Experienced engineers, precision production machines, precision

inspection equipment with experienced inspectors and QC system to

ensure quality.

Item Name | Customized and reliable sheet metal of different types of metal

stamping parts |

Material | Aluminum, Copper, Brass, Bronze, Iron, Stainless Steel, Aluminum

Alloy, PD, APET, PVC, Plastic, Hot/cold roled steel plate/Steel

belt etc. |

Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating,

the wreath oxygen resin spraying, the heat disposing, hot-dip

galvanizing, black oxide coating, painting, powdering, color

zinc-plated, blue black zinc-plated,rust preventive oil, titanium

alloy galvanized, silver plating, plastic, electroplating,

anodizing etc. |

Applications | Automotive, instrument, electrical equipment, household appliances,

furniture, mechanical equipment, daily living equipment,

electronic sports equipment, light industry products, sanitation

machinery, market/ hotel equipment supplies, artware etc. |

Packaging | Inner plastic bag, outer carton box, and we can also pack products

according to your requirements. |

Our features | A company with industry and trade integration |

Workforce | A group of experienced production technician, sophisticated

engineer and dedicated QC. |

About us | The company was established in 2019, specializing in the production

of CNC/AUTO lathes, springs, shafts, screws, CNC machining

parts, sheet metal parts, stamping parts and other metal parts. Our

main production mode is to design and make samples according

to customers' drawings or samples. |

Main Markets | North America, South America, Eastern Europe, West Europe, North

Europe, South Europe, South Asia, Africa African |

How to order | * You send us drawing or sample * We carry through project assessment * We give you a design * You think the design is ok * We make the sample and send it to you * You think the sample is good then place an order and pay us 30%

deposit * We start to make the product * You pay us the balance after you see the B/L Copy * The whole order is done, thank you!! |

What is the minimum order quantity for custom processing and how is

the sampling fee calculated?

Answer: The minimum order quantity is subject to business

communication and negotiation, and the proofing fee is usually more

expensive than the price of bulk goods, because it is impossible to

ask the material supplier to cut a small piece by pieces when

loading materials, and it is impossible for CNC wire cutting

programming to be as convenient as mass production.

Why do some manufacturers offer higher prices and some

manufacturers offer lower prices?

Answer: Every factory has its operation mode. Although the

mechanical processing equipment is similar, the workmanship and

sense of responsibility are quite different. The price-performance

ratio can't be defined simply by the price or scale. Any product

that deviates from the quality and service is a one-shot deal and

won't last long. We only make the best products, receive every

customer with the fastest and best service, and make every customer

our long-term customers.

Service We Provide:

fine sandblasting parts

fine sandblasting parts knurling parts

knurling parts CNC engraving parts

CNC engraving parts powder coating parts

powder coating parts CNC machining parts

CNC machining parts bending parts

bending parts 4-axis CNC machining parts

4-axis CNC machining parts anodize finished parts

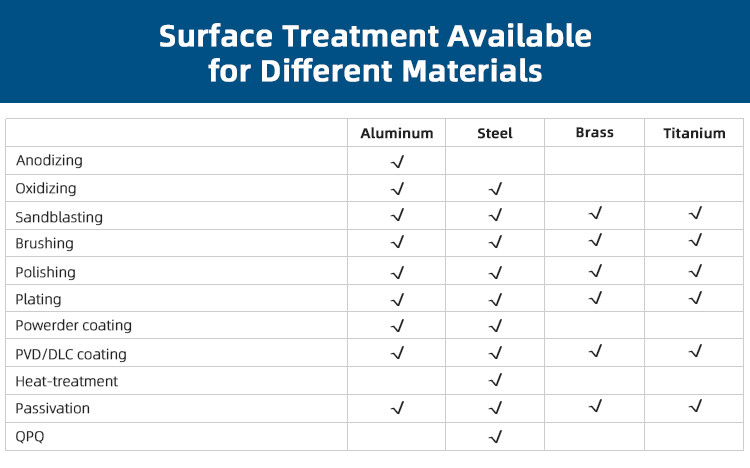

anodize finished partsSurface treatments we can do:

Most CNC factories only focus on CNC machining, but are not good at

surface treatment. If the surface treatment of parts does not meet

expectations, it will not only increase the cost, but also affect

the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we

will choose suitable surface treatment process according to

different parts materials and uses.

The common surface treatments of YMP include: electroplating,

electrophoresis, painting, powder spraying, sand blasting,

polishing, shot blasting, laser engraving, etching, CD pattern,

silk screen printing, wire drawing, blackening, anodizing, hard

oxidation, thick film oxidation, micro-arc oxidation and so on. No

matter what personalized requirements your parts need, we can meet

them.

blackening

blackening CD pattern

CD pattern Electroplating

Electroplating mirror finish

mirror finish powder coating

powder coating etching

etching blasting

blasting anodizing

anodizingMaterials we used for CNC machining parts:

There are various parts that can be processed by CNC, involving a

wide range of industries.

YMP has many years of experience in making OEM parts, and there are

475 kinds of materials. Basically, we can process all the metal

materials in the market, and we are equipped with spectrometers to

ensure the authenticity of the materials. So you don't have to

worry about material problems when you choose YMP. We have stocks

of aluminum alloy, stainless steel, magnesium alloy, titanium

alloy, zinc alloy, nickel alloy, copper, steel, and so on.

aluminum alloy parts

aluminum alloy parts brass parts

brass parts stainless steel parts

stainless steel parts titanium alloy parts

titanium alloy parts