Shenzhen Yi Xin Precision Metal And Plastic Ltd |

|

Item | Value |

| Place of Origin | China |

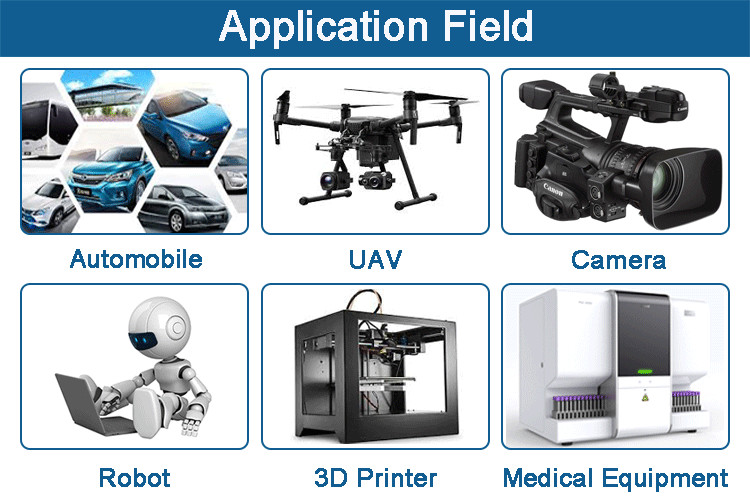

| Application | Bicycle Accessories, Medical Equipment,automation equipment, Furniture. Automobile manufacturing, construction machinery, rail transit, communication industry, consumer electronics industry, instrument manufacturing, energy saving and environmental protection industry, machine tool industry, safety and fire protection industry, pneumatic industry, automation equipment industry, industrial robot industry, textile industry, Semiconductor Industry, Transportation Products Industry, Motor Industry,etc. |

| Model number | Non-standard |

| Material | Carbon Steel, Alloy Steel, Aluminum Alloy, Stainless Steel, Brass, Copper, Iron, Cast Steel, Thermoplastic, Rubber, Silicone, Bronze, Cupronickel, Magnesium Alloy, Zinc Alloy, Tool Steel, Nickel Alloy, Tin Alloy, Tungsten Alloy, Titanium Alloy, Hastelloy, Cobalt Alloy, Gold, Silver, Platinum, Thermosetting Plastics, Foamed Plastics, Carbon Fiber, Carbon Composites, Magnetic Materials |

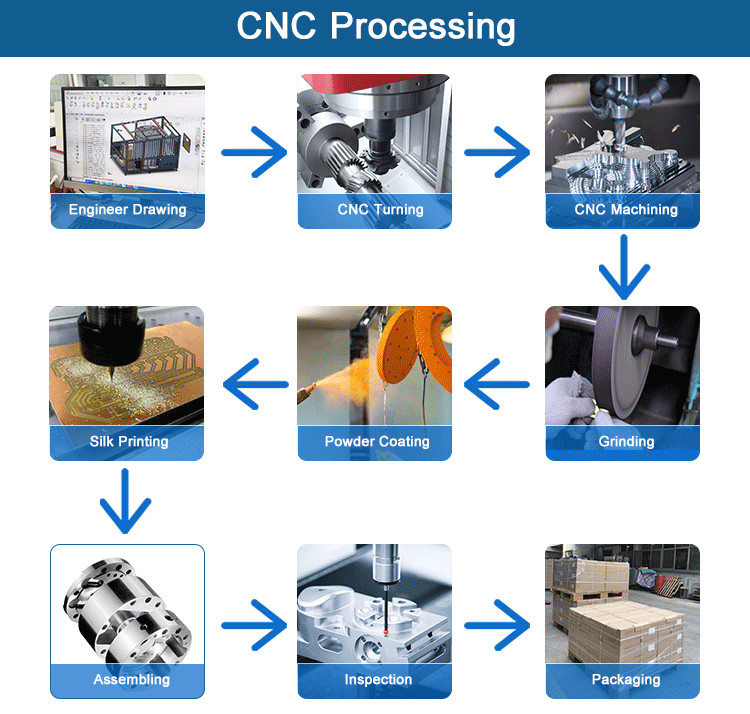

| Our Services | CNC Machining, Tooling fixtures design and fabrication, Metal sheet fabrication, Stamping, Die casting, Plastic injection, Surface Treatment, Mould, etc. |

| Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Surface Treatment | Anodizing, Sandblasting, Painting, Powder coating, Silk Printing,

Brushing,Polishing, Laser Engraving, Electrophoresis, Powder spraying, Electroless plating, Electroplating, Sandblasting, Anodizing, Electrolysis, Laser engraving, Grinding, Shot blasting, Blackening, Phosphating, Passivationetc. |

| Testing Machine | CMM, 2D Projector, Vernier caliper, Micrometer caliper, Roughness tester, Thread cauge, Diameter micrometer, Height cauge, Hardness tester, etc. |

| Packing | EPE foam/ Anti-Rust Paper/ Stretch Film/ Plastic bag +Carton, Wooden boxes, or as per the customers requirements |

| Size | Customized Sized Acceptable |

Spray painting and powder spraying are two common surface treatments in hardware parts spraying, especially for precision parts and small batch customization. They can protect the surface from corrosion and rusting, and can also achieve beautiful effect. Powder spraying and painting can be customized with different textures (fine lines, coarse lines, leather lines, etc.),different colors, and different glossiness (matte, flat, high gloss).

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.