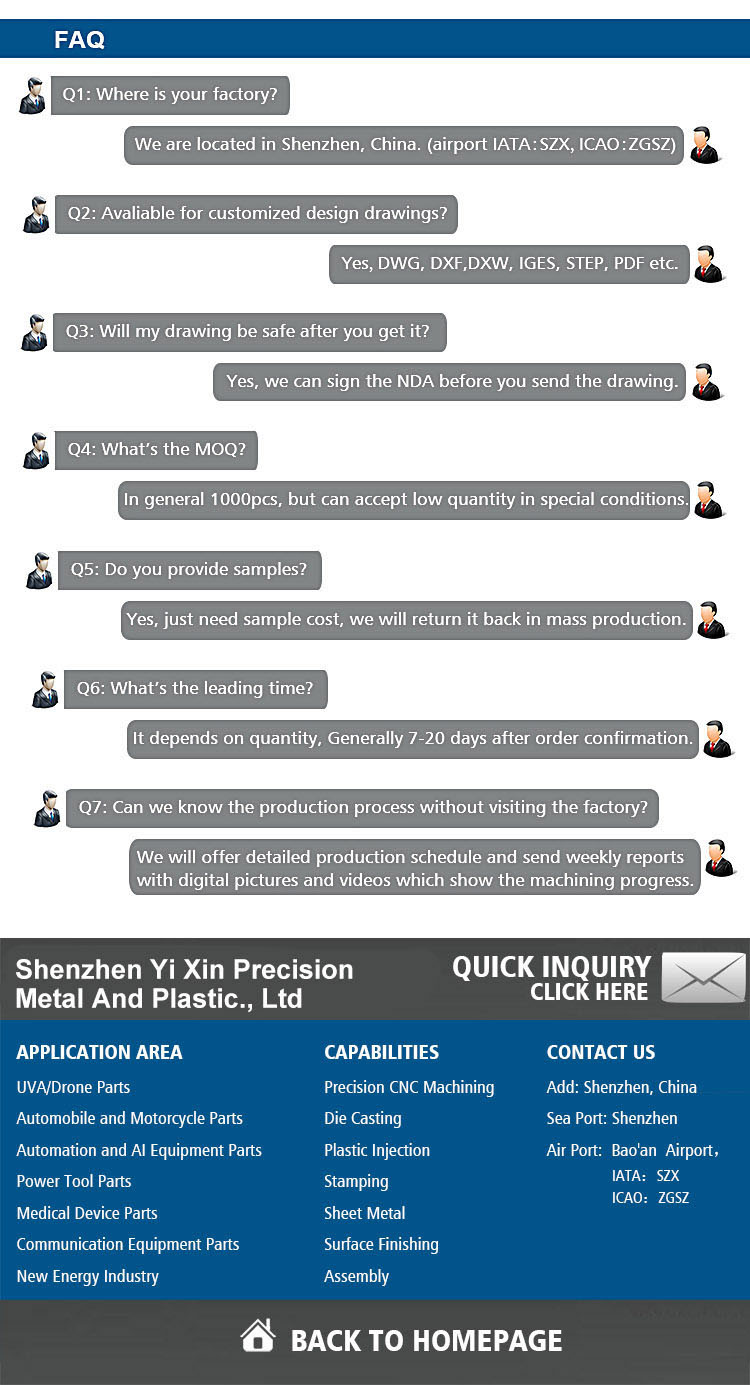

Shenzhen Yi Xin Precision Metal And Plastic Ltd |

|

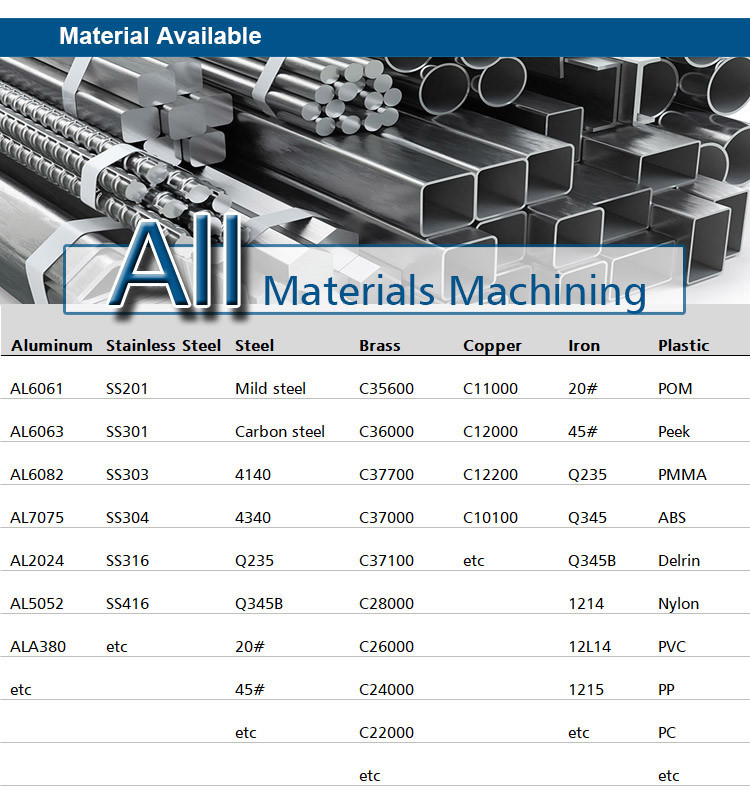

Carbon steel (CRS/SPCC, SECC,etc),Stainless steel, spring steel, Bronze (berylium, phosphor, etc), brass, copper alloy, aluminum alloy, checker plate,tinplate, nickel silver, cold roll steel, hot roll steel, zinc plate etc | |

Metal processing available | CNC lathe milling, CNC lathe turning, drilling, tapping, CNC finishing, CNC laser cutting, flame cutting, punching, stamping, pressing-folding, bending-welding-CNC machining, drilling-welding-spray, tapping, bending and forming,coating-assembling-packing |

Surface Finished: | Powder Coated, Hot Galvanized, Painting, Polishing, spray coating,

Brushing, Cataphoresis, sandblasting,

electroplate ,Passivation |

Specification | OEM/ODM, according to customer's drawing or sample |

Tolerance | Stamping parts:0.01-0.1mm, CNC machining parts:0.1-0.002mm |

Files Formats: | Pro/Engineer, Solidworks, Auto CAD |

Major Equipment: | LASER Cutting Machine |

CNC Shearing Machine | |

CNC Punching Machine | |

CNC Bending Machine And Robot | |

TIG Welding Machine And Robot | |

MIG Welding Machine | |

Spot Welding Machine | |

Rolling Machine | |

Alu And Steel Pipe Bender | |

Burring Machina | |

Milling Machine and Squeezer Riveter | |

Stamping Machine | |

Product include | varieties of metal stamping parts, metal press stamping parts, metal welding parts, metal drawing parts, metal punch parts, CNC Metal parts, CNC metal machining parts, CNC metal machined parts, CNC metal milling aluminum parts, CNC metal turning stainless steel parts, Metal chassis, metallic cabinets, metal cabinets, metal cases, metal enclosures, metal boxes metallic machinery casing, metallic communication products, metallic auto parts, metallic refrigerator parts, metallic washing machine parts, vending machine shell fabrication, communication cabinet fabrication, mold designing making and so on. |

New energy auto parts are mainly parts processed by CNC technology. Obviously, it is widely used. Most of the sheet metal parts on the car, such as various rotating shafts, rotating shafts, gearboxes, gears, hubs, brake drums, mechanical shafts, threads, etc., are processed by CNC. In a word, most of the parts of the car are related to CNC machine tools, that is, the parts are processed by CNC lathe controlled by computer. By CNC processing, the products have the advantages of stable quality, high precision and high production efficiency.

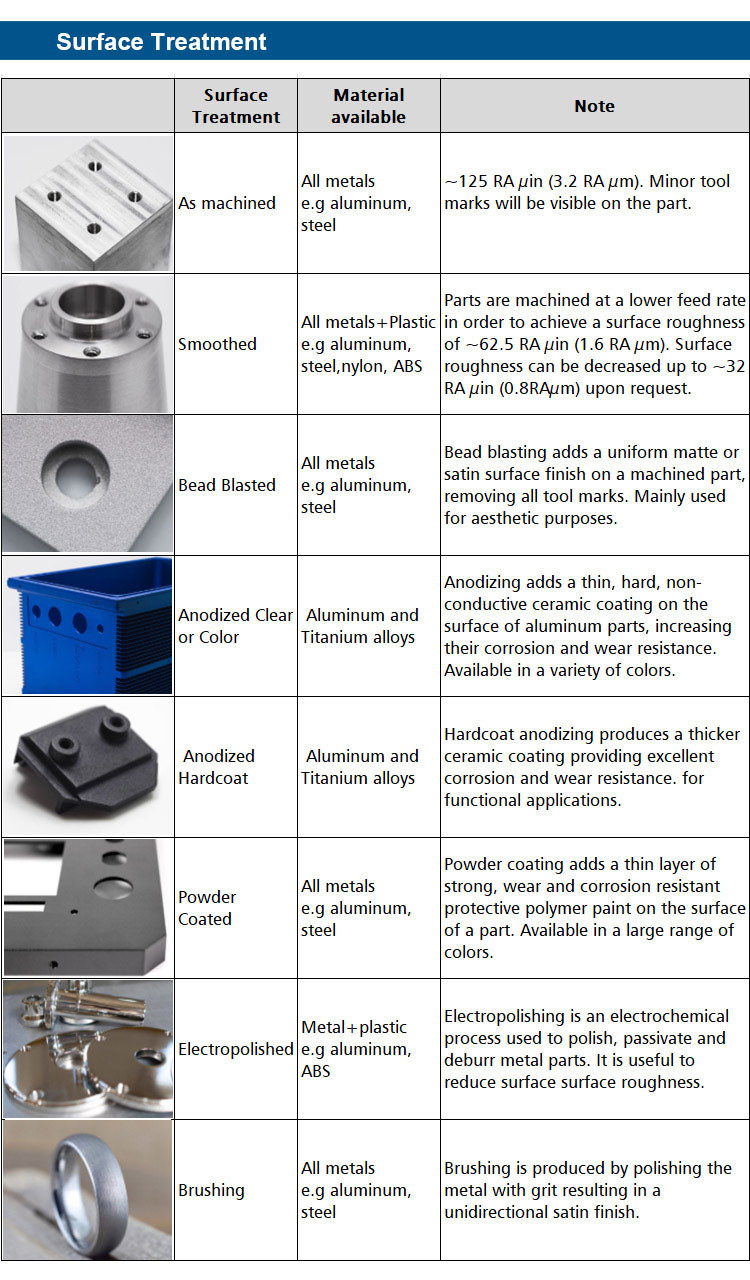

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.