Shenzhen Yi Xin Precision Metal And Plastic Ltd |

|

We Support Custom CNC Machining Parts of Most Materials (Non- Standard Parts) | ||||

Quotation | According to your drawing(size, material, thickness, processing

content, and required technology, etc) | |||

Tolerance | +/-0.005 - 0.01mm(Custonize avaiable) | |||

Surface Roughness | Ra0.2 - Ra3.2(Custonize avaiable) | |||

Materials Avaiable | Such as aluminum, copper, stainless steel, iron, PE, PVC, ABS, etc. | |||

Surface Treatment | Such as polishing, general oxidation, hard oxidation, color

oxidation, surface chamfering, tempering, quenching, etc. | |||

Processing | CNC Turning, Milling, turning-milling compound, drilling, auto

lathe, tapping, bushing, surface treatment, etc. | |||

Drawing | 1.) Pls provide design drawings and contact our Alibaba sales

manager, if there are no drawings can send samples/sample photos to

get a free quotation. 2.) To help us offer the best service for you. Pls be sure your

drawings are clear and accurate(including processing quantity,

materials, precision tolerances, surface treatment, and special

requirements) | |||

Our Benefits | 1.) Over 18 years of experience in CNC machining area and have a

senior design and production team to offer perfect modification

suggestions. 2.) Quickly quote & Quickly Deliver. 3.) We borne 100% responsiblity for quality problems. | |||

Material Available | |||||

Aluminum | Stainless Steel | Brass | Copper | Plastic | Iron |

AL6061 | SS201 | C35600 | C11000 | POM | 20# |

AL6063 | SS301 | C36000 | C12000 | Peek | 45# |

AL6082 | SS303 | C37700 | C12200 | PMMA | Q235 |

AL7075 | SS304 | C37000 | C10100 | ABS | Q345B |

AL2024 | SS316 | C37100 | etc | Delrin | Q345B |

AL5052 | SS416 | C28000 | Nylon | 1214/1215 | |

ALA380 | etc | C26000 | PVC | 12L14 | |

etc | C24000 | PP | Carbon steel | ||

C22000 | PC | 4140 / 4130 | |||

etc | etc | etc | |||

Surface Treatment | Material Available |

As machined | All metals |

Smoothed | All metals+Plastic (e.g aluminum, steel,nylon, ABS) |

Powder Coated | All metals ( e.g aluminum, steel) |

Brushing | All metals (e.g aluminum, steel) |

Anodized Hardcoat | Aluminum and Titanium alloys |

Electropolished | Metal+plastic (e.g aluminum, ABS) |

Bead Blasted | Aluminum and Titanium alloys |

Anodized Clear or Color | Aluminum and Titanium alloys |

At present, with the rapid development of all walks of life, the market demand for precision aluminum alloy parts is increasing, the product shape and structure are becoming more and more complex, and the industries for which aluminum alloy parts are applied are becoming more and more extensive. Customers are demanding higher and higher product quality and delivery time. Then, quality control has become the first consideration of CNC manufacturers. Regarding quality control, Yixin Precision does this.

First, the selection of raw materials; The characteristics and functions of different materials are different, which guarantees the functions of parts, and the purchased raw materials must meet the requirements of customers. Yixin Precision selects the most suitable aluminum alloy material for processing after the 3D drawings, samples and requirements provided by customers.

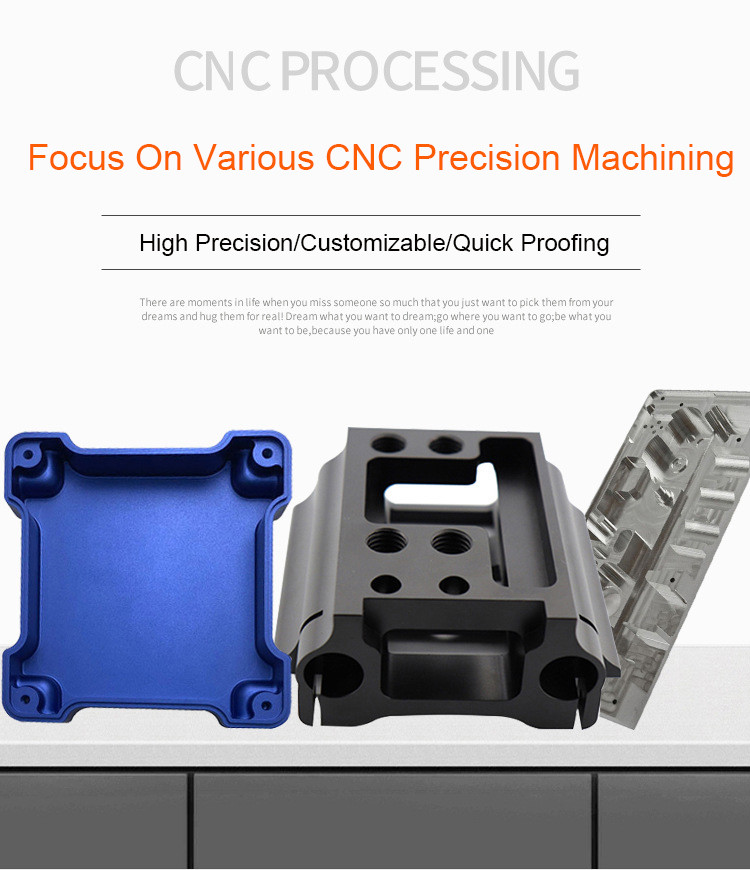

Secondly, it is the aluminum alloy processing technology; At present, the advanced CNC machining center in the machining industry is used for processing, which is characterized by small error, high precision and fast product forming speed, and can process precision parts with complex shapes and structures. After the aluminum alloy is processed, it will be polished by the manual department to make the surface of the product bright and round.

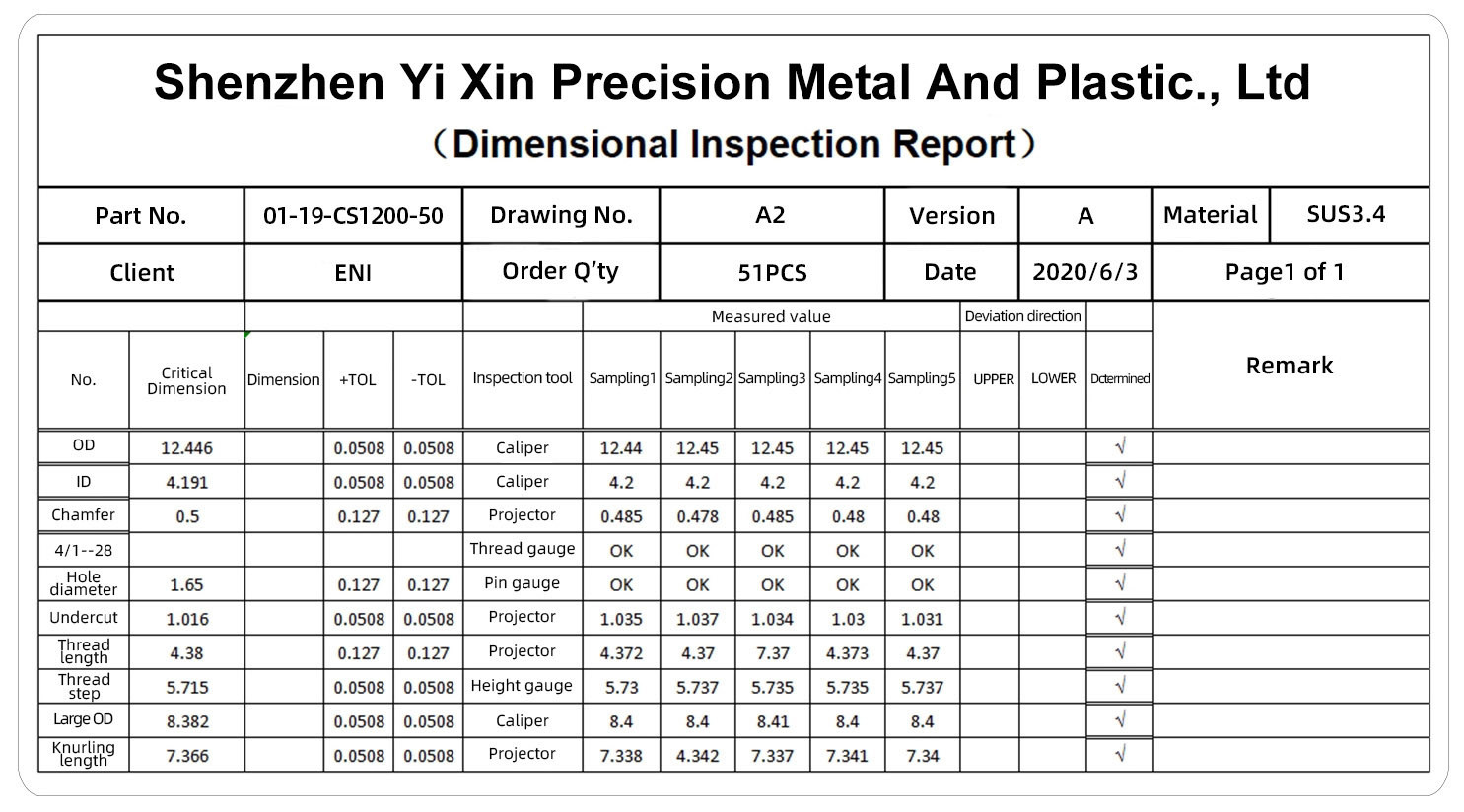

Finally, it is quality inspection; Hand-finished product surface treatment and initial inspection will be delivered to Yixin Precision Quality Inspection Department for quality inspection of the whole product. This step consists of three steps: size, weight and appearance of aluminum alloy parts. After quality inspection, they are packaged and mailed to customers. Ensure that the products delivered to customers meet the requirements or even exceed customer expectations.

Yixin Precision has been engaged in the machining industry for more than 20 years, with 165 sets of advanced CNC machining centers, cooperated with more than 3,000 enterprises, and has a professional technical team and pre-sales and after-sales service system. We provide customers with one-stop processing services.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.