Shenzhen Yi Xin Precision Metal And Plastic Ltd |

|

YMP is a factory that professionally design and produce magnesium, aluminum, zinc alloy die casting, gravity casting, stamping, aluminum profiles, and CNC machining. It provides all-round production services from the design and development of mould to the forming and post-processing of casting products and surface treatment.

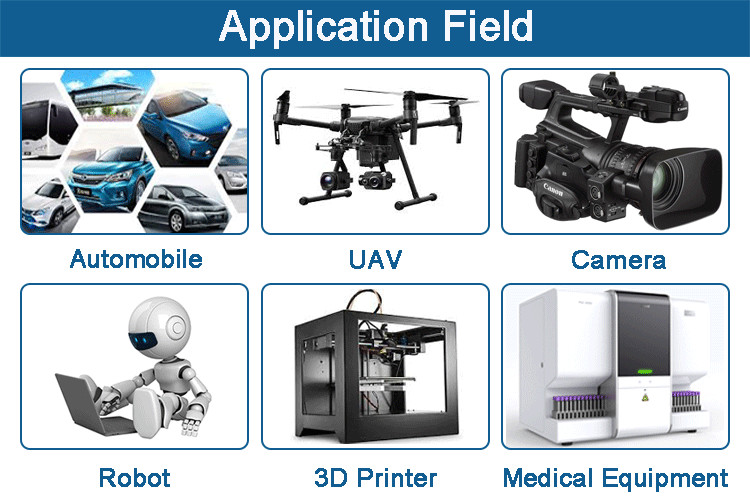

The products are mainly used on 3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment and so on. It is exported to Europe, America and Southeast Asia.

YMP Industry was founded in 2004, has 18 years’ experience about development and manufacture management, It has more than two dozen patented technologies (including two invention patents) and was recognized as a national high-tech enterprise in December 2017, We have obtained ISO9001:2015 Certificate in May 7th 2012.

Our company's production workshop consists of mould department, casting department, processing department, CNC department, paint department, etc. It has 12 professional die design engineers, senior mould making technicians, die-casting engineers, and CNC programmers. The quantity of production workers can be reach to two hundred. Not the best, only better! We hope we’ll be the one of the hardware casting specialist. Welcome to pay a visit to our company.

| Product Name | Customized Sheet Metal stamping part |

| Material | SPCC,mild steel, stainless steel, aluminum |

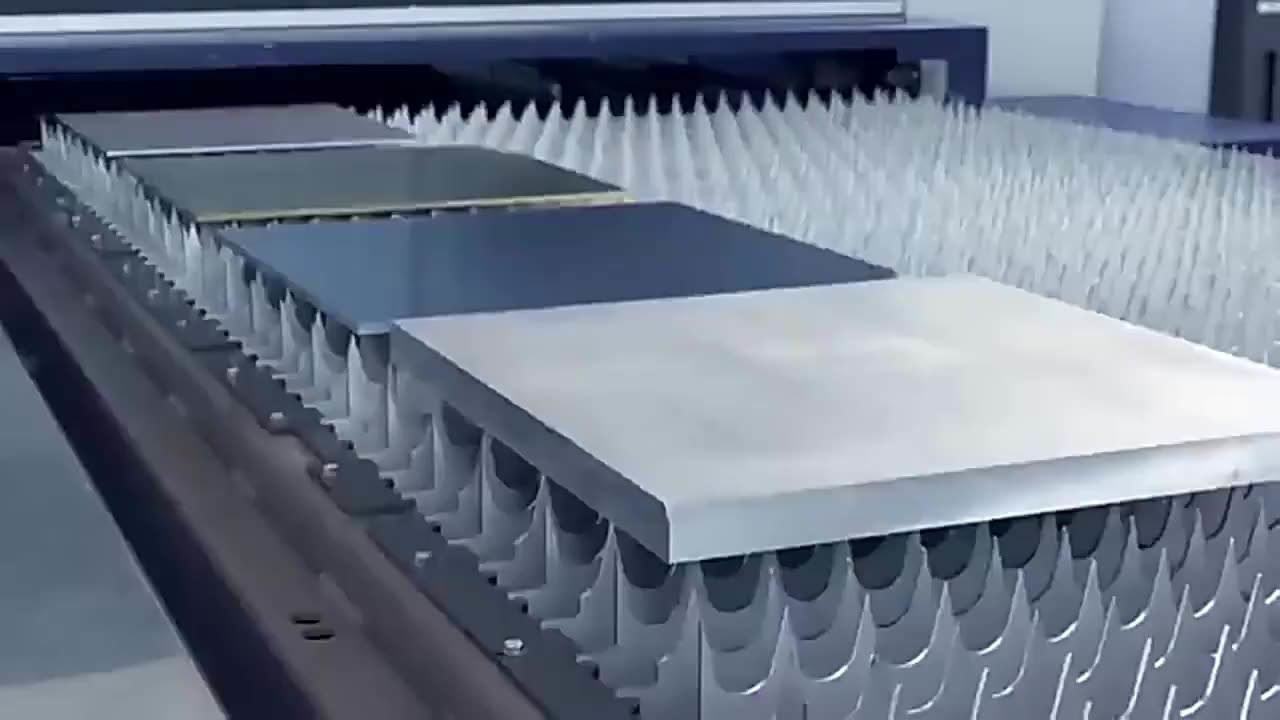

| Machining Equipment | laser cutting machine, bending machine, welding machine, 3-5 axis cnc milling machines, CNC lathes, EDM machines, Grinding machines. |

| Finish | painting, powder coating, plating, plising, anodize |

| Inspection equipment | CMM, Tool microscope, multi-joint arm, Dial gauge, Marble platform, Roughness measurement, Digital height gauge, caliper, Projection machine, Hardness tester and so on. |

| Drawing Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Packaging | 1. Standard strong carton package + Pallet/ Wooden case |

| 2. Per customer's requirements | |

| Delivery | Sample: 5-10 days |

| Mass Production: 15-30 days depends on quantities | |

| Application | Aerospace, Aviation, Agriculture, Marine, Electronic, Automobile, Communication, Drone, Medical, Solar energy, Home Appliance, etc |

> > Laser engraving process forms LOGO and pattern on the product by laser beam, and can also remove the surface treatment coating of the product, which is concave. Silk-screen printing products are raised by transferring LOGO and patterns to products through ink adhesion.

> > The color of LOGO and pattern of laser engraving process is the natural color of materials, while the color of LOGO and pattern of screen printing process, that is, the color of ink, is customizable.

> > In terms of wear resistance, the effect of laser engraving is more durable than that of silk screen printing.

> > The cost is different, the laser engraving process is more economical, because it doesn't need film, but screen printing does.

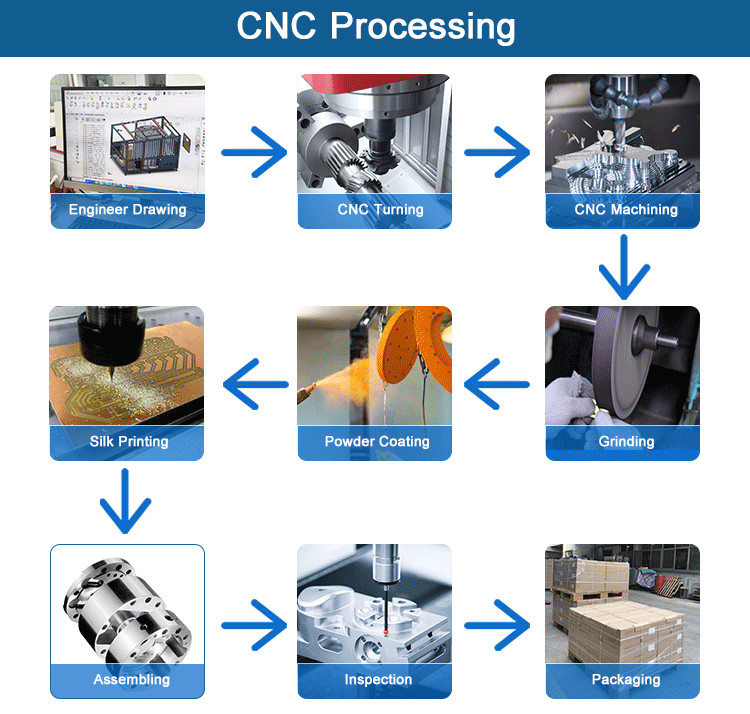

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

1) Inquiry--provide us with all clear requirements (total qty and package details).

2) Quotation--an official quotation form with all clear specifications from our professional team.

3) Marking Sample--confirm all quotation details and the final sample.

4) Production--mass production.

5) Shipping--by sea or by air.

As for the payment terms, it depends on the total amount.

By Sea, By Air, By courier, TNT, DHL, FedEx, UPS Etc. It is up to you.

Sample usually takes about 10-20days depending on product type. Bulk order usually takes about 35 days.

Please e-mail us, and tell us about your market with MOQ for each order. We would send the competitive price list to you ASAP.