Shenzhen Yi Xin Precision Metal And Plastic Ltd |

|

The sample fee will be free if we have it in stock, you just need to pay the shipping cost is OK. Sample of your own design needs to pay for the mold setup charge. Samples production takes 5-7 working days after set up charge received & size drawing approval.

Send your detailed request → Feedback with quotation → Confirm quotation & make payment → Make size drawing for approval → Make mold → Mold test → Making samples → Samples test(Approval) → Mass production → Quality checking → Packing → Delivery → After Service → Repeat Order.

There are 5 options to pay the order: Bank Transfer; Western Union; Paypal; Payoneer, and Alibaba Trade Assurance. Kindly choose the most suitable way for you to arrange it.

Most of the goods were sent out by international airway express companies like DHL, UPS, FedEx, and TNT. Usually takes around 3-4 working days (door-to-door service). We also can arrange shipment via seaway.

Yes, we will try our best to give you help. Because we have our own factory to produce. We can flexible to adjust our production schedule.

Sure, we will not display any customers' designs or show them to other people, we can sign NDA.

If you are interested in motorcycle spare parts, please contact us freely.

| Material of motorcycle spare parts | Stainless Steel, Aluminum, Brass, Bronze, Carbon steel and ect. environmental protection material. |

| Size of motorcycle spare parts | Customized according to your drawing. |

| Surface treatment of motorcycle spare parts |

*Passivation *Polish *Anodizing *Sandblasting *Electroplating(color, blue, white, black zinc, Ni, Cr, tin, copper, silver) *Black oxide coating *Heat-disposing *Hot-dip galvanizing *Rust preventive oil

|

| Tolerance of motorcycle spares parts | +/-0.01mm to +/-0.05mm |

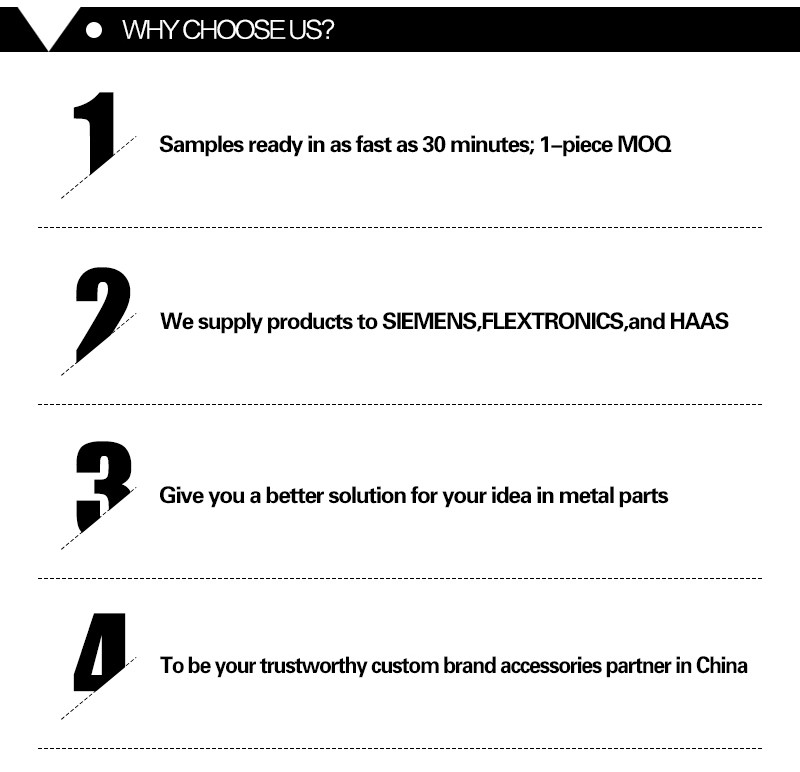

| Minimum order quantity (MOQ) | 1 piece |

| Samples | Yes |

| Certificate | ISO9001:2015 |

| Production Capacity | 2,700,000 pieces per month |

| Payment Terms | T/T, Paypal, Western Union, L/C or Trade Assurance 30% deposit & balance before shipping. |

Yixin Precision CNC Machining Factory believes that in the design of process standards, the correct selection of positioning data has a crucial impact on ensuring the processing requirements of parts and arranging the processing sequence reasonably.

The reference is divided into fine datum and rough datum: the rough reference is used as the positioning reference with the unmachined appearance on the blank. The fine reference takes the machined appearance as the positioning reference.

(1) Benchmark coincidence criterion:the processed surface design data should be selected as accurately as possible to prevent data dislocation from forming positioning error.

(2) Consistent datum criterion:in order to ensure the relative orientation accuracy between the machined surfaces, as many surfaces on the workpiece as possible should be processed using the same set of fine benchmarks.

(3) Benchmark criterion of workpiece machined surfaces:the repeated machining method of two machined surfaces can be used as mutual reference.

(4) Self-reference criterion: Some surface finishing processes requires small and uniform machining tolerance, and the machined surface itself is often used as the precision benchmark.

The four criteria mentioned above for selecting fine benchmarks are sometimes not satisfactory at the same time, and must be decided according to the actual situation.

(1) The rough benchmark should be used in the first workpiece processing. Whether the rough benchmark is selected correctly is not only related to the processing of the first working procedure, but also has a great influence on the whole working procedure of the workpiece.

(2) Principle of reasonable distribution of machining tolerance:the machining allowance of workpiece appearance should be uniform, and the important appearance should be taken as the rough benchmark.

(3) Easy-to-install clamp rule:In order to make the workpiece position stable and clamp firmly, Yixin Precision reminds you that the approximate reference point to be selected should be as smooth and clean as possible, free from lightning strikes, and the forging cut or other defects allow a satisfactory supporting area.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

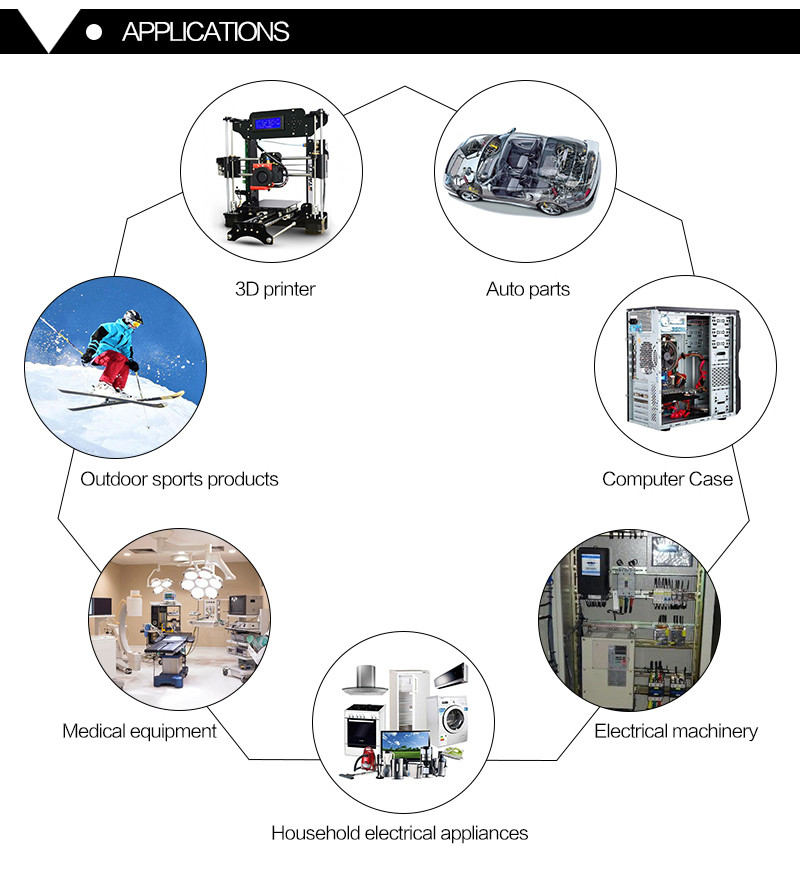

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.