Shenzhen Honreal Technology Co.,Ltd |

|

Verified Suppliers

|

|

Flux Residual PCBA Cleaning Machine Chemical Clean And DI Water Rinse Machine

Features:

1.Through clean rosin flux, water-soluble flux, non-clean flux, solder paste and other organic and inorganic contaminations.

2.2-layers cleaning basket: 610mm(L) ×560mm(W) × 100mm(H) x2

layers.

3.State of the process is visible through a large observation

window.

4.Clean detergent heat system heat cleaning detergent to a certain

temp, raise cleaning efficiency and reduce clean time.

5.Easy operation interface, quick setting clean parameters.

Different passwords can be set.

6.Inner filter makes detergent used repeated. Real-time measure DI

water resistivity and monitoring cleaning effect. Resistivity range

is 0~18 MΩ.

7.The remaining detergent in the pump and pipes are blown off by

compressed air and flow back to cleaning tank. This function saves

detergent up to 50%.

8.High standard cleanliness, ionic contamination completely meets

the requirement of IIPC-610D I class.

9.Totally SUS304 structure, very firm and attractive.

Technical Parameters:

| Content | Parameter |

| Model No | HR-Q6 |

| Clean area size | L610*W560*H160mm 2layer |

| Concentration tank capacity | 30L |

| Dilution tank capacity | 70L |

| Spray tank capacity | 17-23L |

| Sprayer heater power | 6KW |

| Cleaning time | 0~ 99 minutes(adjustable) |

| Cleaning temperature(liquid) | Room temperature ~75℃ (adjustable) |

| Rinse time | 1 minute/time(1-59 times/adjustable) |

| Rinse temperature(DI water) | Room temperature~75 ℃(adjustable) |

| Drying time | 0~99 minutes/(adjustable) |

| Resistivity monitoring range | 0~18M |

| Solvent tank heater power | 9KW |

| Drying temperature | Room temperature~99 ℃/ (adjustable) |

| Drying heater power/KW | 6KW |

| Injection pressure | 30PSI- 90PSI (adjustable) |

| Chemical-grade filter | 0.22μm (filter particles:solder paste, rosin, flux and contaminants) |

| Di water filter | 1 inch fast junction type interface |

| Chemical discharge port | 1 inch fast junction type interface |

| Real-time pressure gauge | 3 PCS (nozzle/DI water/waste) |

| Horizontal spray pump | 5.5KW |

| Exhaust port size | Φ100(W)*30mm(H) |

| Power ;air source | AC380V 50HZ 65A/0.45MPa~0.75MPa |

| Net weight | 400kg |

| Dimension | L1400*W1350*H1830mm |

Shenzhen Honreal Technology Co.,Ltd is a national high-tech

enterprise,Specializing in smt equipment research and development,

production, sales. Services for the world's top 500 electronic

companies.The registered capital of the company is 5 million.Since

the establishment of the company, Honrealhas persisted in the

development of technology as the core, quality as its survival,

independent research and development, and continuous innovation.

After continuous efforts, it has a number of high-tech invention

patents .

Q1: What is the cycle time of HR-Q6 batch cleaning machine?

A1: Total 30~45min. wash 10min+rinse 10min+dry 10~25min.

Q2: What liuqid can be used in HR-Q6 to clean PCBA?

A2: Water-based PCBA cleaning liquid wash, DI water rinse.

Q3: Have many pcbas can HR-Q6 clean in one cycle?

A3: L200*W100mm size PCBA for example, it can clean 30~40pcs.

Q4: Does the PCBAs need to bake after wash, rinse and dry process in the machine?

A4: Sure, PCBAs after clean need to put into electric oven and bake for 2 hours at 100~110℃ or 4hours at 80~90℃to make the PCBA totally dry.

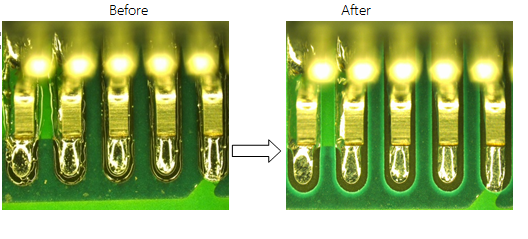

Comparison pictures before clean and after clean:

| Company | Shenzhen Honreal Technology CO.,Ltd. |

| Address | No15,Shangnan Hongma Road, Shajing Street, Baoan District, Shenzhen, Guangdong Province, China |

| Tel | +86755 2302 0279 |

| Fax | +86 755 2330 6782 |

| Zip code | 518125 |

| Skype/Whatsapp/Wechat | +8613715227009 |

| Email: | Monica@szhonreal.com |