Xinshizhan Precision Co., Ltd. |

|

Verified Suppliers

|

|

Product pictures:

Xinshizhan Precision co., LTD, mainly do precision hardware processing, non-standard parts machining, and machinery parts. We are dedicated in manufacturing of custom products for OEM market.

| |||||||||||||||||||||||

Why choose us?

1. High skilled and well-trained working team under good management environment.

2. Quick response and support for any inquiries.

3. Over 10 years professional manufacture experience to ensure high quality of your products.

4. Large and strong production capacity to meet your demand.

5. High Quality standard and hygienic environment.

6. We have very strict quality control process:

In coming Quality control (IQC) – All incoming raw material are checked before used.

In process quality control (IPQC) – Perform inspections during the manufacturing process.

Final quality control (FQC) – All finished goods are inspected according to our quality standard for

each products.

Outgoing Quality Control (OQC) – Our QC team will 100% full inspection before it goes out for

shipment.

Proper Quarantine procedure – For those products got rejected to pass the quality control, they will

specially marked and dispose.

7. Good after sales services

8. Passed ISO 9001 and provide SGS/ RoHS certification if needed.

Factory details and display

| Equipment List | Brand | Model | Working Track | Tolerance(mm) | Quantity(Set) |

| CNC Machines | FS (TW) | KMC-L850 | 800*500*500 | & plusmn;0.01 | 6 |

| FANUC | a-D14MIA | 500*400*330 | & plusmn;0.001 | 10 | |

| BROTHER | TC-S2DZ | 500*400*300 | & plusmn;0.001 | 12 | |

| Taikan (TW) | 500*400*300 | & plusmn;0.001 | 15 | ||

| BROTHER | TC-31A(Double Table) | 300*250*350 | & plusmn;0.002 | 5 | |

| FS (TW) | 4 Axis CNC | 500*400*300 | & plusmn;0.001 | 5 | |

| TSUGAMI | CNC lathe Center | 530*1500 | & plusmn;0.001 | 15 | |

| Mazak(5-Axis) | I-600 | 510*910*510*360°*(-120°-30°) | & plusmn;0.001 | 2 | |

| TSUGAMI | CNC Milling and Turning Machine | 530*1500 | & plusmn;0.001 | 5 | |

| WEDM-HS | Tianlong | DK7728 | 230*280*400 | & plusmn;0.02 | 8 |

| Laser Engraving Machine | Aprime | CJ-CO2-10 | 250*250 | ±0.001 | 1 |

| Drilling Machine | West Lake | Manual | 15 | ±0.01 | 5 |

| Tapping Machine | West Lake | Manual | 25 | ±0.01 | 5 |

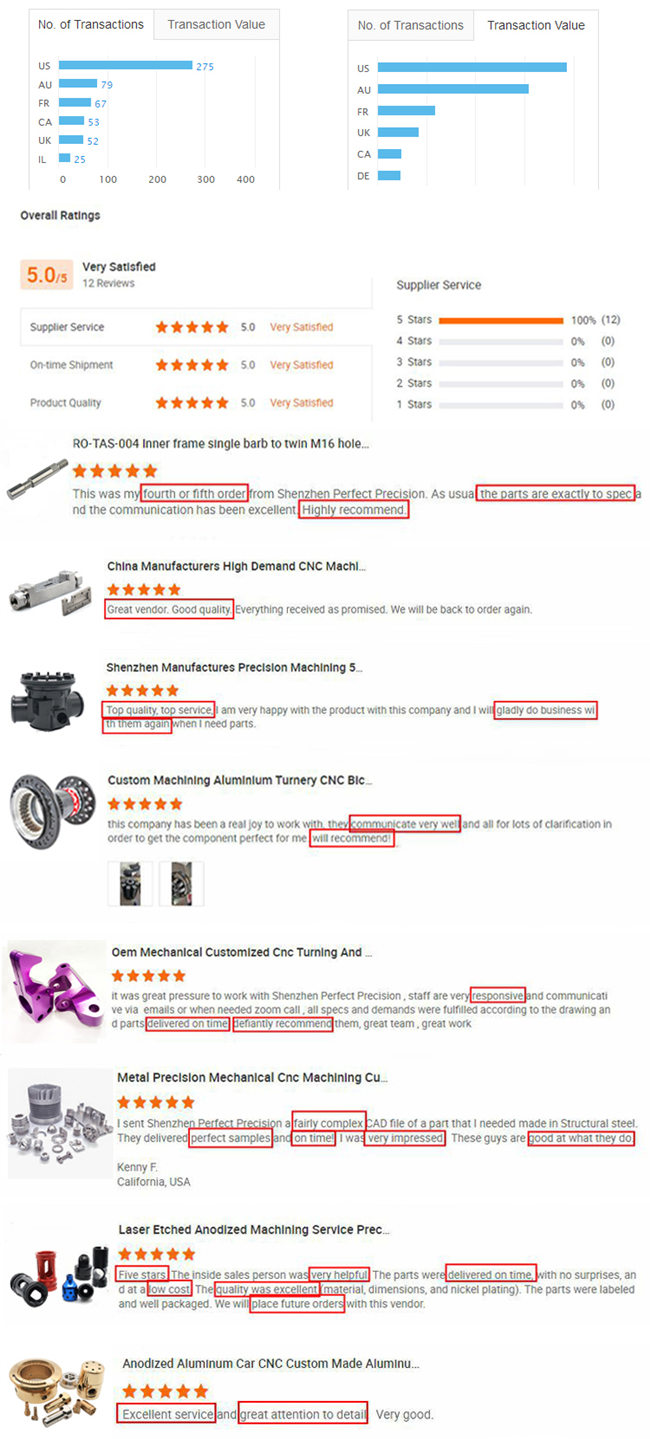

Customer Feedback

FAQ:

Q1:Where can I get product&price information?

A1:Send us e-mail , we will contact you as we receive your mail.

A2: Depending on your specific project, it usually takes 10 to 20 days.

A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

A4:Yes, we can make measurement based on your samples to make drawings for machining parts making.