Guangzhou Ruihe New Material Technology Co., Ltd |

|

Verified Suppliers

|

|

High-Temperature Silicone Rubber RH6022FR® Fire Resistant Silicone Rubber Heat Resistant Rubber

Description

Rui-He RH6022FR ® is a kind of ceramifiable Silicone Rubber Compound for Silicone-insulated Safety Cables (Fire Resistant Cables)

It can be used to produce diving supplies with high thermal stability and excellent resistance to acid and alkali.

Key Features and Benefits

Typical Properties

| Unit | RH6022FR ® | ||

| Appearance | / | White | |

| Shore A Hardness | A | 60 ± 2 | |

| Tensile Strength | MPa | ≥ 5.0 | |

| Elongation | % | ≥ 450 | |

| Tear Strength | KN / m | ≥ 10 | |

| Linear Shrinkage | % | ≤ 0.1 | |

These figures are for reference only, please contact us for details.

The mixing ratio of components A: B = 1: 1.

Vulcanization: 150 °C / 5 min

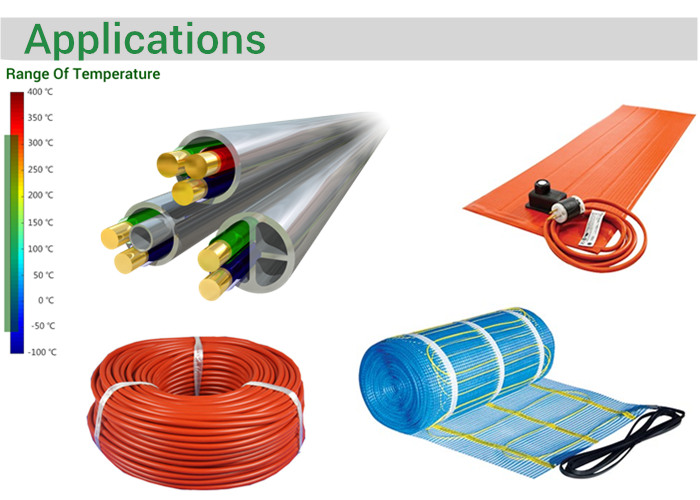

Applications

Because of the outstanding properties RH6022FR ® liquid silicone rubber is particularly suitable for water tubes, a slide pad, sealant rings, suction cups, and a shower head.

Certificate

| RUI-HE® RH6022FR | ||||||

| ISO9001: 2016 | FDA | RoHS | REACH | PAHS | SGS | MSDS |

Packaging & Storage

Available in 20kg boxs.

Store in a cool, dry place out of direct sunlight, use it within 12 months from the day of manufacture.

Applications

• Cake Mold

• Chocolate Mold

• Life casting

• Sex toy

• Sex doll

• Stone Mold

• Other use that needs fast curing and food grade silicone

Notice

This product cannot be contacted with compounds containing N, P, S to avoid affecting the catalytic effect of platinum.

FAQ

Q: Is silicone safe for applications involving rapid decompression?

A: Silicone is very permeable to most gases and as such would not

be ideal for use in applications involving rapid decompression.

Q: Can silicone be used for high traffic surfaces?

A: Products made from silicone should not be used in high traffic

applications because even the best high strength compounds have a

relatively modest resistance to abrasion wear.

Q: Why are some silicones specified as "addition cure"?

A: Some silicones are described as addition cured because the cure mechanism is a catalyst reaction between the component ingredients within the compound. These components need to be added together for the compound to cure hence the term addition. Addition cure compounds can be supplied as one, two or three component.

If you need to know the prices of our silicone rubbers, please

contact us. We do not provide prices on the website because prices

fluctuate for many reasons.