Ningbo Suijin Machinery Technology Co.,Ltd |

|

Customized Stainless Steel 304 316 Nipple Pipe Fittings Investment Casting for Valve Pump

Ningbo Suijin can supply different kinds of pipe fittings used in piping systems. Pipe fittings come in various shapes and sizes. Such as Elbow, Reducer, Tee, Coupling, Adapters, Union ,Valve, Cross, Olet, Cap, Plug, Swage Nipple, Expansion Joint, Bush, Long Radius Bend, Steam Traps, Flanges.

These pipe fittings can be found in various pressure classes , We also different forged carbon steel fittings.Pipe fittings are used to join pipes together. Component of the piping system that aids in Elbows and tees change the flow direction. Reducers and reducing tees change the pipe’s size. Various parts, like couplings, are used to connect and stop flows.

In general application, cast iron pumps are water pump casting. They are more used for water transporting. Stainless steel pumps are for transport corrosive media.We will adopt quenching and tempering heat treatment processes. To improve the mechanical properties, hardness, wear resistance, and strength.We offer cast pump body, pump housing, impeller casting, and pump mounting bracket. As well as other pump castings for the oilfield, oil extraction, and refining, petrochemical, water treatment industries, solid waste treatment, concrete construction, and so on.

Ningbo Suijin can cast various hardware thin-walled parts for

customers, which are light in weight and complex in shape. We adopt

all-silica sol dewaxing precision casting, paraffin investment

precision casting, die casting and other processes, specializing in

the production of precision castings and products of various

materials.Widely used in hardware tools, machinery manufacturing

and machining industries, and in the shipping sector are grades,

aviation products, auto parts, water pumps, pneumatic tool

accessories, lighting hardware, valves, architectural hardware,

lock accessories, valve castings, door hinges, Stair handrail

accessories, pipe joints, etc., and can support casting, heat

treatment, shot blasting, gross machining services according to

customer requirements.

Hardware Castings details

| Product Name | Pipe Fitting Hardware Castings |

| Processed | Silicon Casting and Machining |

| Material | SUS 430 |

| Weight | 0.3-0.8 kg |

| Application | Exhaust system |

| Casting tolerance | Investment casting ISO 8062-3 DCTG 5 |

| Casting Surface condition | Ra3.2 um |

| Surface treatment | None |

| Brand | Ningbo Suijin |

Hardware Castings Picture show

Our Quality control

1) We possess a large scale of foundry and CNC machines, as well as production lines of lost wax casting to cater to the need of growing precision investment casting business. Besides, we have advanced inspecting instruments such as Spectrometer, Metallographic Microscope, Tension Tester, and Impact tester for Chemical & Physical Analysis, and 2D projector, X-ray, Ultrasonic , magnetic to keep inner good instruction, CMM to assure dimensional precision.

2) Quality control starts the minute the precision investment casting raw material arrives the foundry, continues along with every stage of investment casting process. We were awarded with ISO9001:2000 by SGS, PED/AD2000 by TUV.

3) We have developed and manufactured more than 3300 types of precision investment casting products, which are widely applied in Auto Parts, Construction Hardware, Marine Hardware, Pumps & Valves, Machine Parts and other industries. A large percentage of our investment casting parts were exported to Europe, US, Japan and Asia.

Our invertment precision casting

lost wax precision castings Packing

Technique: Precision casting, Investment casting, Lost wax casting, Stainless steel precision casting

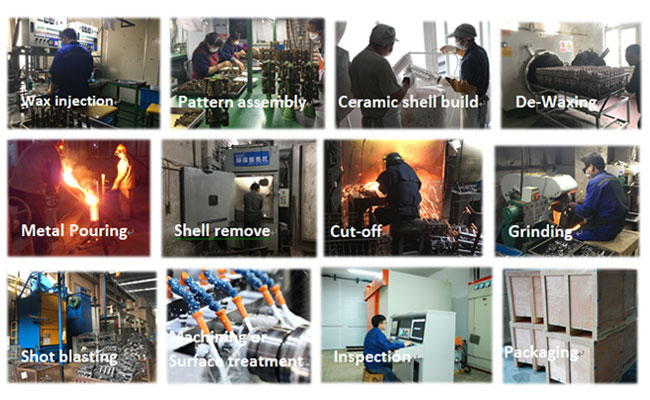

Lost wax castings parts Process flow chart

Wax Injection→Make Wax pattern and repair→Inspection→Shell Making→De-waxing→Roasting Shell and Melting Steel→Composition Inspection→Pouring→De shelling→Cutting and Grinding the pouring gate→Inspection→Heat treatment→Shotblasting→Machining→Anti-Corrosion→Final Inspection→Shipping

Process flow:

Wax Injection--Make Wax pattern and repair--Inspection--Shell

Making--De-waxing--Roasting Shell and Melting Steel--Composition

Inspection--Pouring--De shelling--Cutting and Grinding the pouring

gate--Inspection--Heat

treatment--Shotblasting--Machining--Anti-Corrosion--Final

Inspection--Shipping

Why choose Suijin?

1. We are specialized in producing kinds of investment casting parts.

2. Supply Customized Stainless Steel Precision lost wax Investment Casting

3, We can offer you the one-stop solution from 3D design to product forming and also provide the mold components during the mold lifetime. All the quality process full according to the TS 16949 process

4, We have always carried out the human-based management, so everyone would be always responsible to their own work.

5, We have owned experienced engineer in the mold department and mold injection department and then we can provide not only mold but also products.

6, Our principle is customer is the God, Be committed to the continuous improvement of our product quality, to meet customer need as much as possible.

7, All of our products would be produced by strict control in every machining process. All the threads 100% check by the automatic threads machines

8, We can offer you very low price and best after-sales service in order to promote our big and long cooperation.

9. The professional team with professional experience will help you optimizing the whole solution for you casting designing, casting processing to machining, heat treatment, surface treatment and so on, to lower total processing costs, or achieve value-added products, help you to improve market competitiveness and obtain maximize profits

Our company and factory

We manufactured all kinds of lost wax investment castings and machining parts or called precision investment castings , material including carbon steel, alloy steel, and stainless steel. we also can according to the customers' requirement to compound the material, Our factory has a floor space of 33,000 square meters and another 18000 square meters of building area, which contain both casting foundries and CNC machining area. Our advanced lost wax casting and investment casting production lines have a capacity of 5000 tons lost wax castings and 1000 tons investment castings per year.

Application Information:

Our precision investment casting/ lost wax castings are used in Automotive, motorcycle, valve, marine, machine tools, hardware, railway, gear, impeller, pump, reducer, motor, mining machinery, engineering machinery, transmission machinery, forestry machinery, communal facility, etc.