Ningbo Suijin Machinery Technology Co.,Ltd |

|

O2 Stainless steel oxygen sensor Exhaust Weld Bung

Ningbo Suijin is specialises in manufacturing medium to high-density sintered components for automotive engine, powertrain and exhaust systems. We also manufacture sensor components that cater to global markets. Our product portfolio includes drivetrain gears, engine sprockets, pulleys, crankshaft bearing journals, transmission gears and synchro hubs, as well as ABS rings and Sensor Hego bosses and flanges.We offer an extensive range of Stainless Steel motor vehicle exhaust parts and sections, including mandrel bends, exhaust connectors, exhaust flexi pipes, exhaust reducers, clamps, brackets, adaptors, lambda bosses and much more.

We offer a be-spoke service catering for your every need. Provides its esteemed customers with high-volume, high-precision and low-cost components, tailored to their specific requirements. This is ensured by leveraging the integrated manufacturing facility adhering to rigorous quality standards. The engineering and development centre, and a well-equipped, in-house quality lab help us achieve these goals better.

Stainless steel oxygen sensor exhaust weld bung plugs are universal fitment. It fits M18 x 1.5mm standard thread pitch and 0.5 inch tall for modern O2 sensors and wideband air/fuel O2 sensors. Designed to fit O2 wideband sensors from most manufacturers .The O2 sensor exhaust weld bung plug can seal off any O2 sensor ports not in use or not ready for use and create a tight seal to prevent any exhaust leaks when the oxygen sensor is not in use.

Feature:

Standard size fitment

Easy to install with

M18 x 1.5mm screw-on threads for oxygen sensors or plugged for

future use.

Bungs can be welded on to replace any stripped or damaged O2 sensor

ports.

Use this kit to add O2 sensors to fabricated exhausts.

High-quality mild steel to withstand high temperature environments.

Description:

| Material | 1.4308 (Stainless steel based on standard EN 10283) |

| Process | CNC machining , Turning , Miling , Grinding , with casting and so on |

| Part weight | 0.02-0.3KG |

| Dimension: | M18 (external thread) |

| Packaging Details | each sensor boss packed in green bag , land into carton , Then packed into pallet. |

| OEM | OEM service , work as customer's drawing or sample. |

| Delivery period | 10 working days after received your payment |

| Tolerance of rough casting | ISO8062 IT4-IT6 |

| Used for | Exhaust system oxygen sensor boss |

Picture show

If you need us to submit a quotation,

1. Please provide Stainless steel oxygen sensor exhaust weld bung drawing or sample, the format of the drawing can be PDF, IGS, DWG, STEP, etc.

2. Together with relevant information, such as quantity, weight, material, material grade, tolerance, machining demands, surface treatment, heat treatment, mechanical property requirements, etc.

3. Our specialized engineer will check and quote for you, we would appreciate the opportunity and will respond in 3-5 working days or less.

4. If you do not have a drawing, we can duplicate your Stainless steel oxygen sensor exhaust weld bung sample and make drawing for your confirmation.

Competitive Advantage:

1 . 17 years' casting manufacture

2 . Good team for quality and delivery time control.

3 . Good Projects and PPAP documents experience

4 . We have a team of professional engineers to supply related technology help if customers need our tech-assistant.

5. Close to Ningbo Port and Shanghai Port.

6: Full APQP process to control the quality

7. All of our products are strictly inspected and tested before packing in factory..

8. TS 16949 and ISO 9001 certification by TUV and PED certification by TUV

9. First-class product quality and service by best facilities, management and techniques

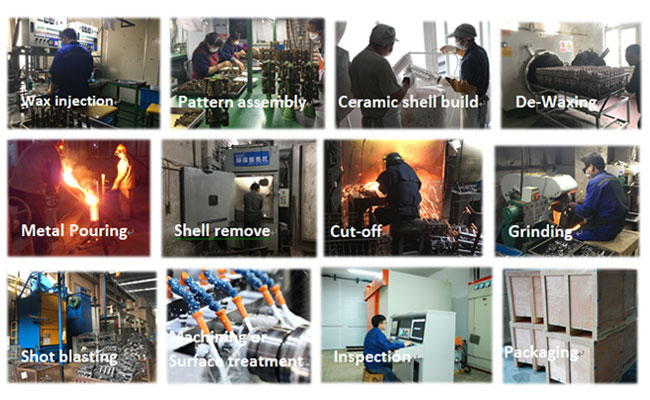

Our invertment precision casting Process flow:

Wax Injection--Make Wax pattern and repair--Inspection--Shell Making--De-waxing--Roasting Shell and Melting Steel--Composition Inspection--Pouring--De shelling--Cutting and Grinding the pouring gate--Inspection--Heat treatment--Shotblasting--Machining--Anti-Corrosion--Final Inspection--Shipping

Precision Casting Part Packing

Our Company

Our Precision Casting Manufacturing Process