Kaiping Zhonghe Machinery Manufacturing Co., Ltd |

|

Verified Suppliers

|

|

Catalogue ZH excavator boom arm.pdf

1. 14000㎡ Workshop

We has more than 14000㎡ steel structure standard workshop with a large number of high precision processing equipments.

2. High-tech R&D Team

We use precision drawing software to achieve the max working range under the premise of safe operation.

3. Experienced Workers

There are more than 60 skillful staffs, 30 welding workers with over 5 years welding experience.

4. Customization

(1)Match all brand excavator.

(2)Color, length, material can do according to you.

(3)Extra pipeline can be added to suit to some extra application.

5. Prompt Lead Time

(1)Our lead time is 7-15 days.

(2)Our annual output of various types of excavator boom arms can

reach 600 sets.

6. 100% Service

(1)Online support within 24 hours.

(2)Appointment video technical support. (Our engineers have focused

on excavator boom and attachment over 10 years)

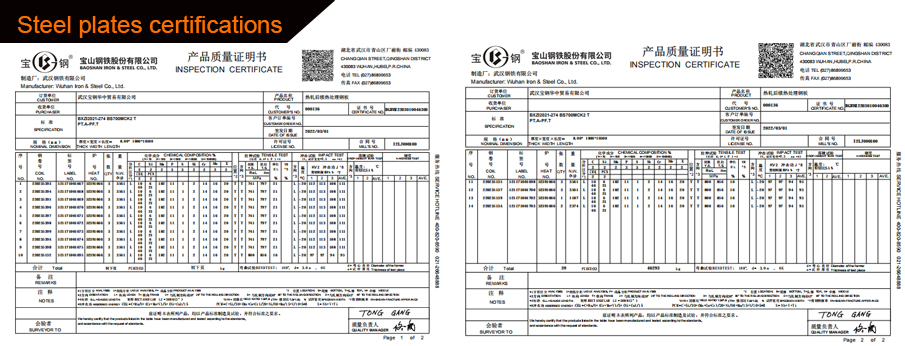

CE certification & Utility model patent certificates

Rock bucket is one of the excavator buckets classified by material. According to material, excavator buckets are divided into standard bucket, strengthening bucket, rock bucket, gravel bucket, etc. Standard bucket material selection of domestic high-quality high strength structural steel 16Mn, suitable for general clay, loose soil excavation and sand, soil, gravel loading and other light working environment. The base plate and side blade plate of the vulnerable part of the strengthening bucket are made of domestic high-quality high-strength wear-resistant steel NM360, which is suitable for digging hard soil mixed with soft gravel or loading of gravel and gravel and other heavy duty operations. The tooth base plate and side blade plate of rock bucket are made of ultra-high strength wear-resistant steel HARDOX imported from Sweden, which is suitable for the loading of heavy duty working environment such as digging hard soil mixed with hard gravel, secondary hard stone, wind fossil or hard stone and ore after blasting.

According to the function of excavator bucket is also divided into ditch bucket, grid bucket, cleaning bucket, tilt bucket and so on. Trench bucket is suitable for excavation of various shapes of trenches. Trench excavation takes shape once, generally without dressing, and has high working efficiency. Grid bucket is suitable for the separation of loose material excavation, excavation and separation of a complete, widely used in municipal, agriculture, forestry, water conservancy, earth and stone works. Cleaning bucket and tilt bucket is suitable for slope and other plane dressing and large capacity of river, ditch dredging, cleaning work, which tilt bucket can change the tilt Angle of cleaning bucket through the oil cylinder, greatly improve work efficiency.

Rock bucket belongs to the structural products, composed of tooth seat plate, bottom plate, bottom reinforcement plate (two layers), side plate, wall plate, hanging ear plate, back plate, bucket ear plate, bucket ear sleeve, bucket teeth, tooth seat, guard plate or bucket Angle and other parts, so welding is the most critical production process of rock bucket, welding quality directly affects the structural strength and service life of rock bucket.

The production process of rock bucket includes blanking, turning, milling, drilling, molding, welding, grinding, sandblasting, spraying and other processes.

Rock bucket is a special industry equipment accessories, need special equipment to high efficiency, high quality operations, such as: CNC plasma cutting machine, groove milling machine, plate rolling machine, welding positioner, boring machine, etc.

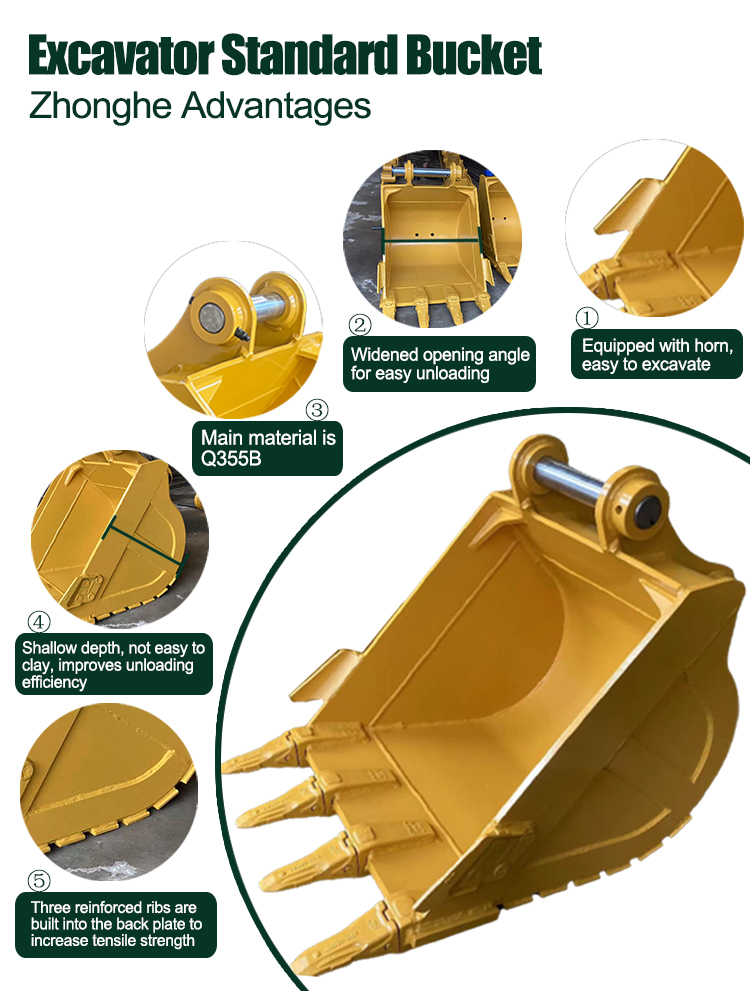

Standard bucket fit most excavators

| Bucket Capacity(cbm) | N.W.(kgs) | Fit exc.(ton) |

| 0.65 | 720 | 13T or above |

| 0.8 | 850 | 16T or above |

| 1 | 950 | 20T or above |

| 1.2 | 1050 | 24T or above |

| 1.3 | 1250 | 26T or above |

| 1.4 | 1350 | 28T or above |

| 1.5 | 1450 | 30T or above |

1. Shallow depth, not easy to clay, improve unloading efficiency

2. Widened opening angle for easy unloading

3. Equipped with horn, easy to excavate

4. Main material is Q355B

5. Three reinforced ribs are built into the back plate to increase tensile strength and prolong its service life

1. Standard bucket

Q355B material, standard plate thickness, and China high-quality bucket tooth base. It is mainly applicable to light operation occasions such as excavation of general clay and loading of sand, soil and gravel.

2. Rock bucket

Q355B material, NM400 optional. On the basis of the standard bucket, reinforcing plates are added at the bottom, and the tooth plate and side plate are thickened. It is mainly applicable to heavy and light industrial occasions such as excavation of hard soil and loading of soil, gravel and gravel mixed with soft sand.

3. Heavy duty rock bucket:

Q355B+Hardox500. On the basis of the reinforced bucket, the bottom plate and side plates are thickened. It is mainly applicable to the excavation of hard rocks, secondary hard rocks and wind fossils mixed in the soil; Loading of hard rock and ore after blasting.

5. Tilt bucket for mini excavator

6. Clamshell excavator bucket

8. Excavator Ripper

6. Hydraulic grabs for excavators

Kaiping Zhonghe Machinery Manufacturing Co., Ltd.,manufacturing and trading combo, specializes in customizing different kinds of excavator boom arm and attachments over 5 years.

We has more than 14000㎡ steel structure standardization workshop with a large number of high precision processing equipment as well as a strong and cohesive team. At present, there are more that 60 experienced technical staffs, 30 welding workers with over 7 years experience, 15 senior designers and a high-tech R&D team.

Our annual output of various types of excavator boom arms can reach

600 sets. We supply products with high quality and moderate price,

which is sell well in more than 40 countries and areas.

We adhere" Merit Quality, Sincerity Management and Customer

Satisfaction", honestly greet customers from home and abroad to

negotiate and cooperate with us.

Please do not hesitate to contact us for coupon, Thank you!