Anhui longmaker Technology Co., Ltd. |

|

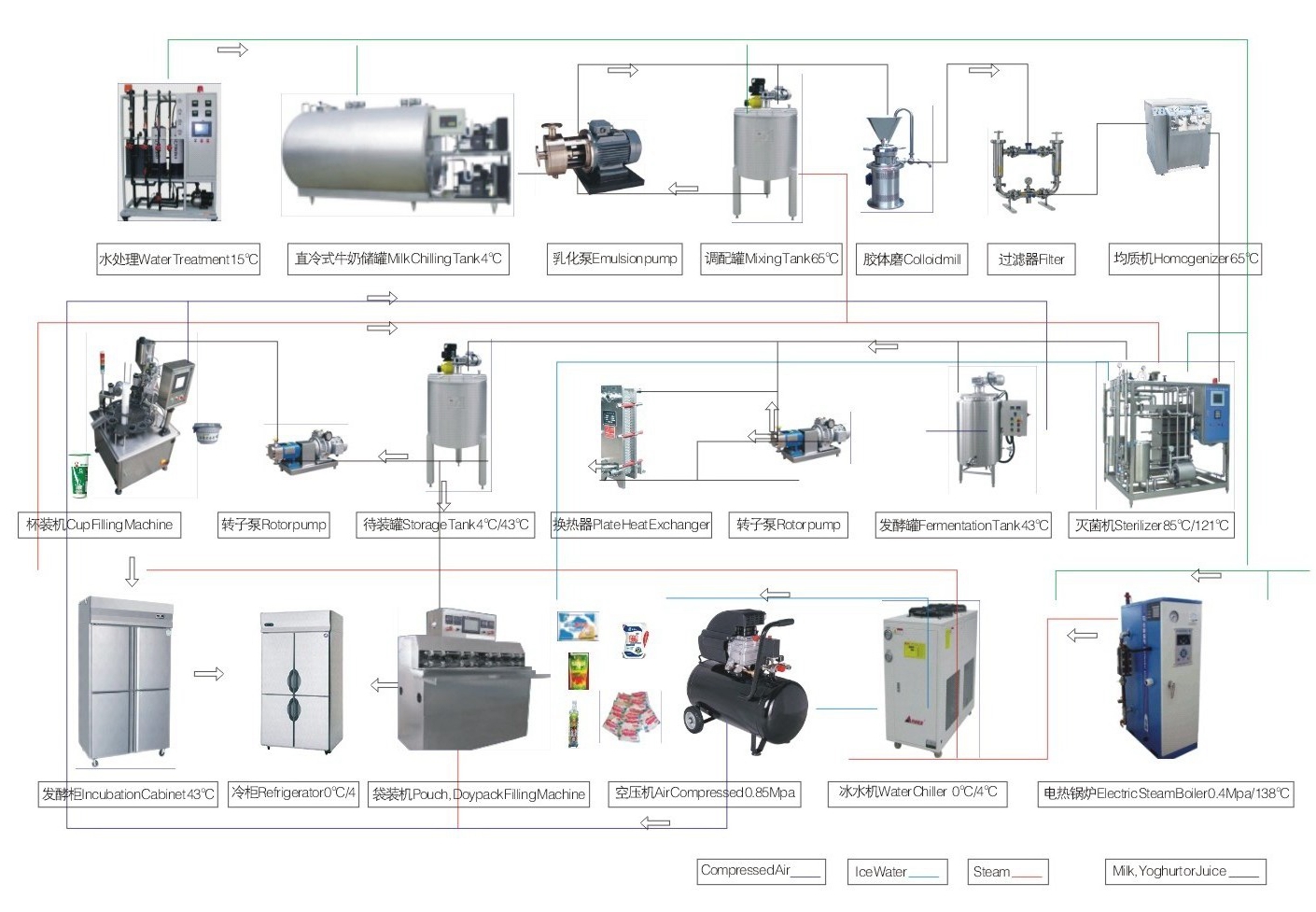

We can provide a complete juice production line

A separate machine can also be provided.

First, the structure and characteristics:

This machine introduces international advanced technology, combined

with the characteristics of the domestic market, developed a fully

automatic PET bottle beer washing and filling capping three-in-one

machine, using stainless steel elastic clip bottle mouth rotary

device, wear-resistant filling head, low loss seal The cover head,

flushing, filling and capping are carried out simultaneously. The

equipment has a compact structure and reasonable process. It is

suitable for all kinds of PET bottles of 250-1500ML, and the

products have reached the international advanced level of similar

products.

1. Flushing device: The bottle cap and bracket are made of

stainless steel. The rotation of the clip is controlled by a

transition device placed at the nozzle below the mouth of the

bottle. Sealing materials in contact with the product are food

grade ozone resistant materials. The solenoid valve controls the

supply of water to the bottle, and the water pressure of the bottle

can reach 0.25-0.30 kg, and the bottle splash-proof device is

washed.

2. Filling device: All stainless steel structure: The filling valve

is made of SUS316L. The internal structure of the base, the drive

device with shifting action, and the star drive gear. The structure

is on the base, the bottle transports the star wheel, the

transmission, the filling part, the cover part; the filling valve

has a guide. Avoid wear to the ring; Glyd ring and O-type silicone

sealing ring, good sealing performance and fast filling speed.

3, capping device: based on the famous Italian AROL capping machine

technology to improve the design of the bottle feeding is guided by

the filling machine star wheel device.

4. Capper: The capper is fixed on the upper part of the body

assembly and driven by a separate motor. During operation, the

motor drives the circular cone to rotate, and the messy stacked

caps are arranged in a certain order through special channels. A

tongue-shaped plate is arranged at the outlet of the passage, and

the function is to remove the back cover from the passage, and use

the blower to cover the back cover and blow back to the silo, and

rearrange to ensure the cap from the capper. They are all covered.

5, transmission system: the use of large gear direct transmission,

smooth operation, good position, maintenance, maintenance is

convenient.

6. Control and protection: The motor is controlled by the frequency

converter to adjust the running speed. All the key parts, such as

the star wheel and the gear, are equipped with micro sensors. If

there are no bottles, bottles or covers, then there are faults. A

sensor transmits the signal to the master and causes the machine to

stop automatically.

7. Material: Stainless steel is made of Japanese SUS304L and A3 and

45 cast steel. The electrical configuration is shown in the

attached table. PLC inverter Japan Mitsubishi, contactor Siemens,

photoelectric switch Korea.

8, pneumatic components: Ya Deke and Kang Maosheng.

9. The hanging air conveying mechanism is adopted, and the bottle

shape is not required to be changed.

The main technical parameters:

1, the number of stations: wash bottle 16, fill 12, cover 6

2, rated production capacity: 2000 ~ 4000 BPH (500ml)

3, rinse bottle water pressure: 0.2 ~ 0.25 Mpa

4, water consumption of washing bottles: 0.6 ~ 0.8 tons / hour

5, filling method: micro negative pressure filling

6, filling temperature: 60C--95oC

7, air source pressure: 0.5 ~ 0.7Mpa

8, gas consumption: 0.4 ~ 0.6M3 / min

9, the main motor power: 3.0KW

10, the total motor capacity: 5.65KW

11, rated voltage: three-phase 380V / 50HZ

12, the host dimensions: 2450 × 1850 × 2550 (length × width ×

height)

13, weight; 3250Kg