Shanghai Liangui Technology Co., Ltd. |

|

Verified Suppliers

|

|

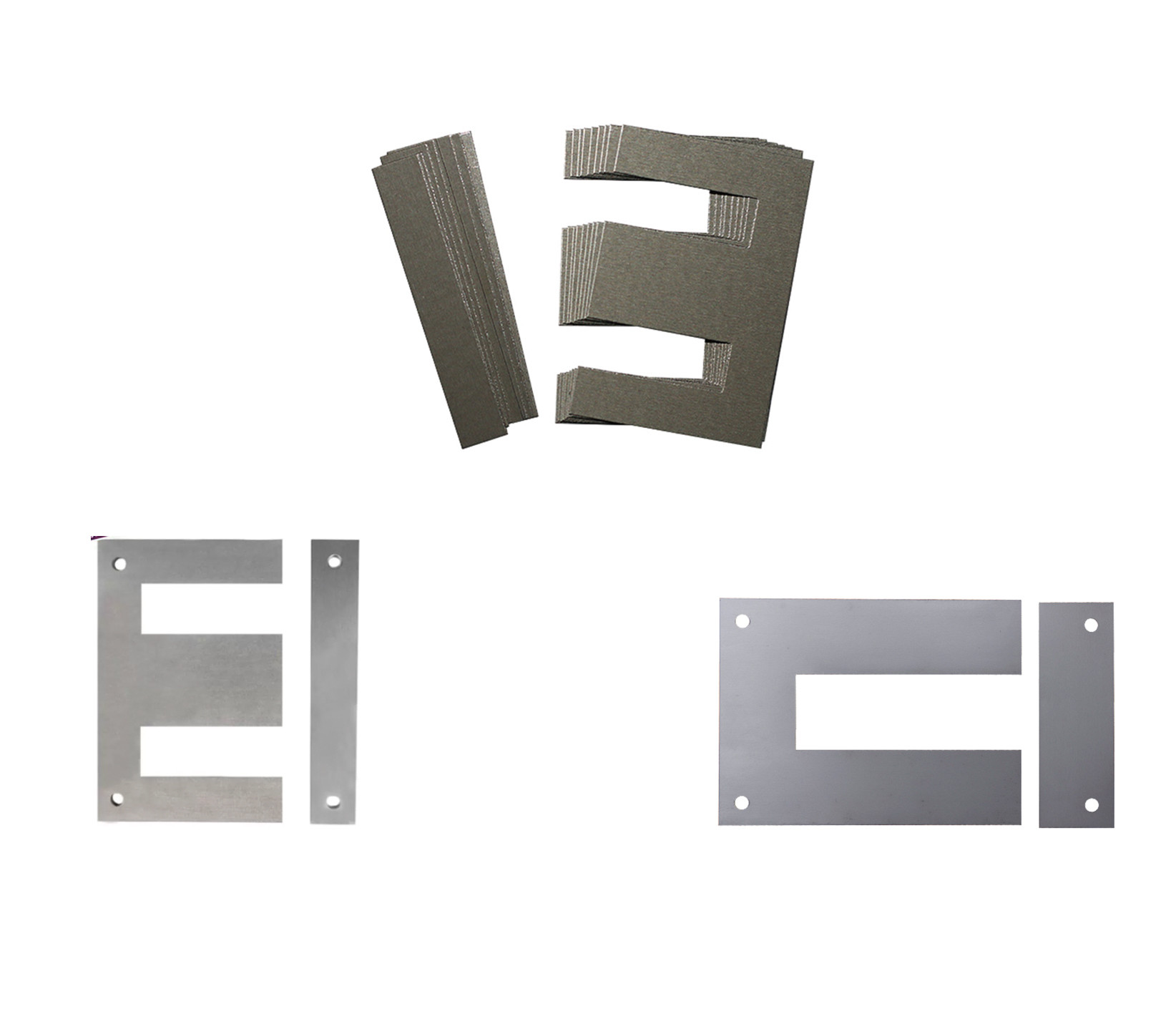

Low FrequencyTransformer Use EI Silicon Steel Sheet Automatic Chip

Lamination Stacking Machine

Product Description

"Transformer Automatic Chip Stacking Machine" is a new product

developed by our company on the basis of "hand-crank chip stacking

machine" (patent number: ZL201430518221.9), which is an automatic

equipment used to stack small transformer EI silicon steel sheet. The plastic core and the silicon steel sheet are manually

placed, the single machine capacity is more than 300PCS/H, and one

person can operate two machines. This product is widely used in the

electronic industry, especially for the automatic assembly of

E-shaped and I-shaped pieces of silicon steel sheet magnetic core

transformers.

Product Parameter:

| Product name | EI type Silicon Steel Sheet stacking machine |

| model | LG2-XXA or Customized |

| Voltage | Input: 220VAC~240VAC 50~60Hz |

| Power | 30~60W (different models with different power) |

| Volume | Type 28 length 580*width 300*height 80mm |

| Type 86 length 680*width 550*height 1400mm (different models have different sizes) | |

| Weight | 15KG~50KG |

| Positioning accuracy | ±0.02mm |

| Control System | PLC+touch screen control system |

| Communication port | 232 connector, support upload, download, operation monitoring and other functions |

| Air supply | 0.3MPa~0.6MPa |

Product Features

① Simple, efficient and easy to use.

It saves manpower and reduces the labor intensity of the manual

rocker arm of the old-fashioned shaker, and novice can be on

the job in just 10 minutes of training.

② The structural part is made of high-quality steel, which has less wear, less failure, long service life, and easy replacement of parts. It is an ideal choice for transformer manufacturers.

③ Using high-performance PLC control, the touch screen control interface is easy to operate.

④ Adopt high-precision, high-torque stepping motor drive, fast speed and long life.

⑤ Card protection system, overcurrent and overload protection.

⑥ Adopt unique triangular structure

Product Instructions

1 Loading, place the EI sheet corresponding to the EI sheet slot.

2 Set the insert parameters of the EI sheet according to the EI and

frame size, and debug it.

3 When the debugging is OK, put the skeleton (wire package) in the

skeleton position, press the start switch (can be started by foot

switch), the machine will automatically complete the inserting

work, confirm that the inserting is completed, take it out, put in

a new skeleton, and then repeat.

Note: Since most of the customer's wire packs are different,

the customer needs to provide some wire packs and "EI" pieces.

Other specifications of EI type insert transformers can be

customized according to customer requirements.

Product maintenance and precautions

1 Regularly clean the air source air compressor of the chip

inserter to ensure that the air intake of the equipment is clean.

2 Ensure that the running track of the inserter connecting rod is

clean.

3 If it happens that the device insert can't run for a while,

please check the proximity switch back to the origin.

4 Pay attention to maintaining the equipment, and do not bring

corrosive substances close to the equipment.

5 It is forbidden to put items other than I and E pieces into the

material slot.

6 When the device is powered on, the human body is prohibited from

approaching the mechanical actuator.

7 When the device is powered on, it is forbidden to manually insert

the wheel (if manual operation is required, please unplug the power

supply in advance)

8 If it is determined that the 220V power supply is connected to

the device, the device is still not powered. Please check the power

switch fuse.

9 Pay attention to the safety of plug insertion and removal to

avoid electrical injury.

Warranty

1. Product warranty period:

The main unit is guaranteed for 1 year, and the main accessories

are guaranteed for 3 months (calculated from the date the buyer

receives the machine)

2. Main accessories: The following accessories are subject to the

actual configuration of the specific model, not for all

machines.

Including: ①host ②foot switch ③power cord

④fuse ⑤trachea

⑥A set of two I-piece blocks ⑦Air source

Company Profile:

Shanghai Liangui Technology Co., Ltd. is committed to promoting the prosperity and development of the

world through technology, focusing on Intelligent Equipment & Automation Solutions to to help enterprises to improve production process and minimize the cost.

We are an intelligent equipment & automation solution integration service provider. Our company has a professional foreign trade sales team and an

experienced technical support team, the principles of our team work

is customer first and fast solution. Our business scope includes Mechanical and Electrical Equipment (Wire & Cable Processing Equipment, EI Lamination Stacking

Machine for low frequency transformer), Industrial Robot, NDT Testing Equipment, Dry Ice Cleaning Machine etc.

Our mechatronics business division is specialized in the R & D, production, sales and maintenance

of Non-standard Mechanical and Electrical Equipment, mainly focused on Wire & Cable Manufacturing industry and Transformer Manufacturing industry. Our company's High-speed Terminal Welding Machine, Wire

Splitting and Twisting Machine, Reflective Light Laminating Machine

and other products have been widely used in the wire and cable

processing industry. The main customers are: Foxconn (Vietnam branch), South Korea's Samsung (Vietnam branch) ), Luxshare Precision and other well-known domestic and foreign companies. Our Smart EI Semi-automatic Inserting Machine, EI Automatic Shaping

Machine and many other products are widely used in low-frequency transformer manufacturers. The main customers are Kangding Electronics (stock code: 830928), Chint Electric (stock code: 601877), Shandong Yuxing Electric, Hangzhou Yuzheng Electric and other national leading enterprises in the production of low-frequency transformers for electric energy meters, which has increased the production efficiency in the industry by 30% and saved various costs by nearly 38%. We continuously improve the production process, create a variety

of new production equipment and automated production processes,

provide customers with various solutions and technical support,

which win the trust and support of customers from all over the

world with an excellent reputation.