smart glass film, PDLC glass film, electric control glass,PDLC

Switchable Film

How to make smart glass / Swichable glass

| Name | Specification | size | Unit | | Delivery time |

| PDLC | Standard film | 0-1800mm | SQM | | 3-7Days |

| pasted film | 0-1500mm | SQM | |

| |

1, glass preparation.

After get the required smart glass size, we make the appropriate

size of the glass, and according to the need to decide whether the

glass edging and edging forms; smart glass with the film

already belong to the safety glass composite, and most of the time

Less use of toughened glass saves money and saves time. However, if

it is necessary to use toughened glass for transportation or

customer needs, it should be possible to control the flatness of

the glass during toughening.

2, The size of the film must be smaller than the size of the glass.

Usually each side of the diaphragm is about 2mm smaller than the

glass, if the condition of the glass edge can be masked during

installation, then it can be a little bigger, but each edge should

not exceed 4mm, to avoid the stress effect; if the glass is spliced

together, Then 2mm is more appropriate, otherwise it will affect

the appearance.

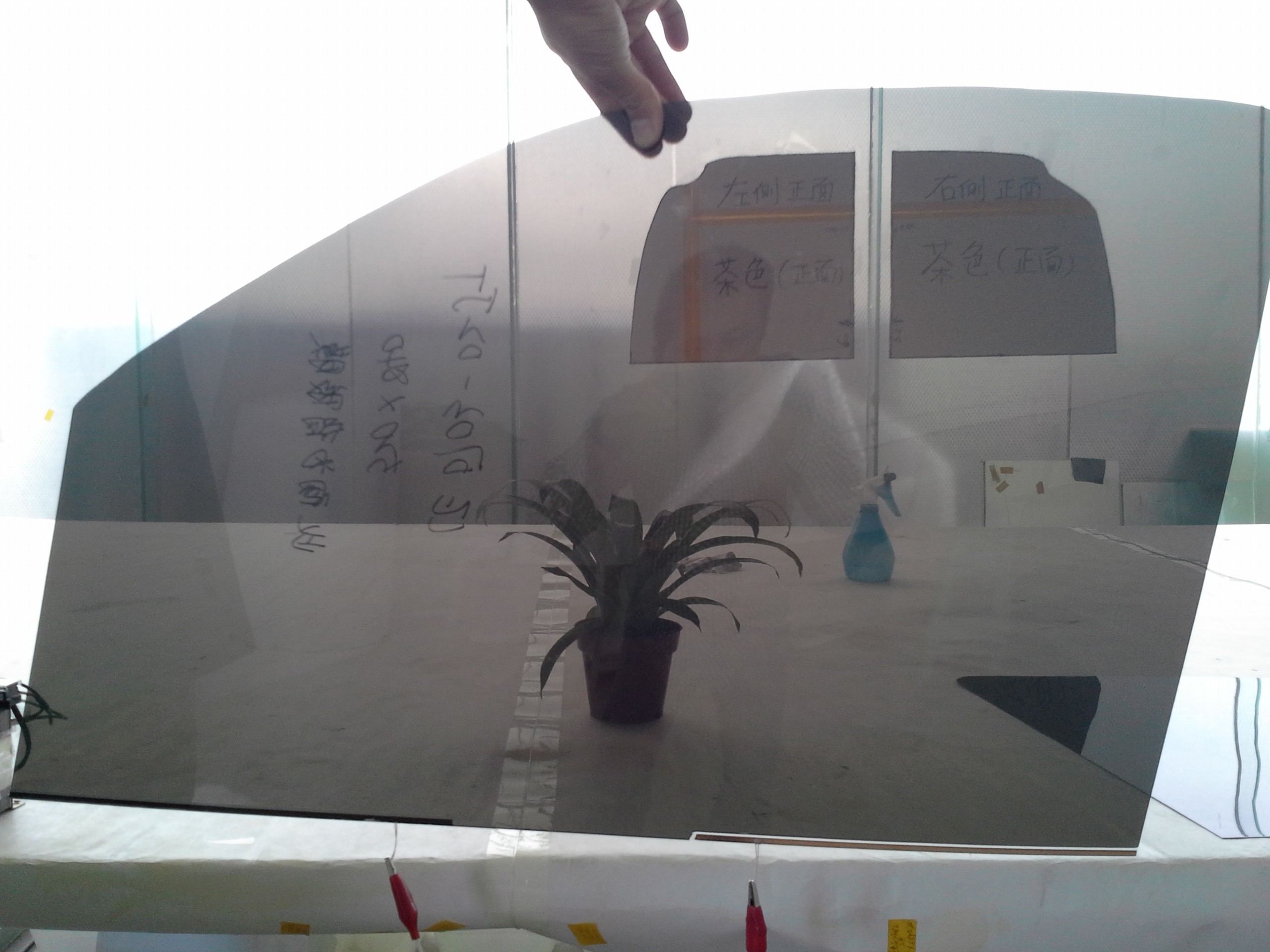

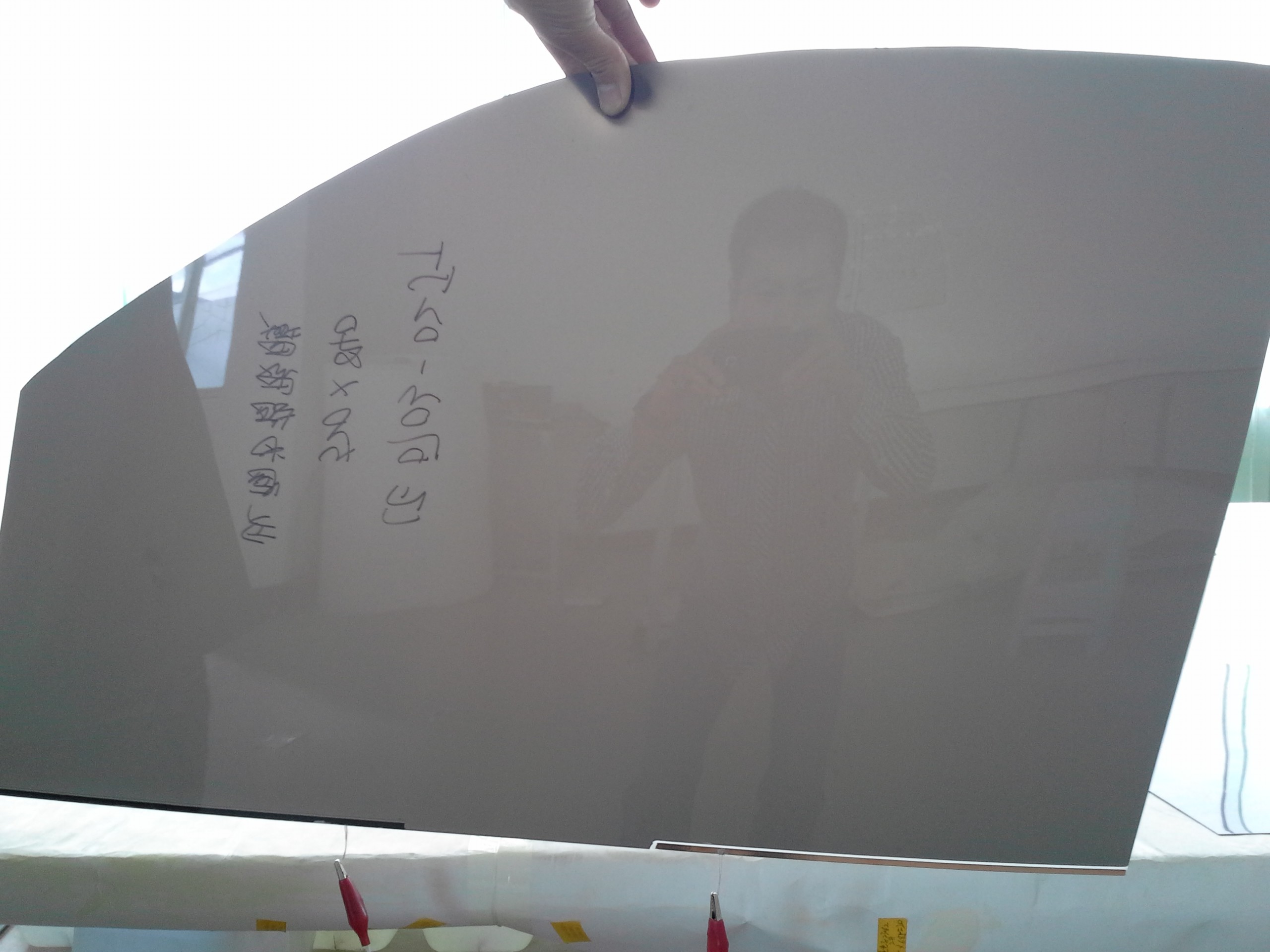

3, Combining the film process.

Switchable glass and other laminated glass and the process is very

close, first of all the glass to be one side of the piece clean,

and then put a film; check the film for impurities, and impurities

removed; the Switchable film protection The film is unfolded, and

then the clean Switchable film is placed on the glass on which the

film has been placed in good position; another layer of film is

placed to check whether the film has impurities and the impurities

are removed; and another clean glass , And finally cut out the

excess film (if it is tempered glass to be thick film). Please note

that in the process, it is necessary to check whether the

Switchable film has moved due to your operation. If it is adjusted

at any time, the Switchable film can be bent and can be wrapped,

but it can not be recovered if there is any damage.

4, according to your plastic processing technology, the whole

process of vacuum.

5, After the processing is finished, wait for the glass to cool to

room temperature, then stop the vacuum and remove the glass, modify

the edge and energize the test.

6, Above all, if you follow these to operate has been able to

produce a standard dimming glass, and if you want to improve the

product, please contact us.

Packaging Details

Customized or wooden case

Delivery Time

3~7 days after receiving payment

Lever Industry Co have more than 19 years of experience in the Glass Machine

Industry.

We are Unremitting, Just for Customer Satisfication!

| Contact Person : | Mr. Kevin |

| Job Title : | Sales Director |

| WHATSAPP : | +86 136 5379 2967 |

| Skype : | glasstempering |

| Email : | sales@leverglass.com |

| Website: | www.leverglass.com |