Phoenix (suzhou) electronic Co.,ltd |

|

Application Introduction:

The exposed luminous characters are divided into monochrome, colorful and full-color luminous characters according to their colors. It is composed of a single color word light and a single color word light. The colorful exposed luminous characters are composed of a perforated word shell, a colorful external leakage lamp and a colorful controller. After the lamp is turned on, the colorful gradient can be realized. The full-color exposed luminous words are composed of a perforated word shell, a full-color external leakage lamp and a full-color controller. The program files are made by professional software and placed into the SD card. The SD card is inserted into the full-color controller. After the light is turned on, the external leakage luminous words can play flash animation and character animation, and the effect grade is very high.

High voltage 18v 30ma smd led chip rgb red green blue pink for exhibition light sign light

Quick details:

| Input Voltage(V): | 18-20V |

| Warranty(Year): | 2-Year |

| Type: | Smd Led Chip 2835 |

| Lighting solutions service: | Lighting and circuitry design |

| Luminous Efficacy(lm/w): | 29-32lm |

| Lifespan (hours): | 50000 |

| Working Time (hours): | 20000 |

| Chip Material: | INGAN |

| Emitting Color: | Red green blue |

| Power: | 0.2W |

| Viewing Angle(°): | 120 Degree |

| Color Rendering Index(Ra): | 80 |

| Packing bag: | 220*240nm |

| Place of Origin: | Suzhou ,jiangsu |

| Application: | Exhibition ,sign lights |

| Package Type: | Suface Mount Package |

| Forward Current: | 30MA |

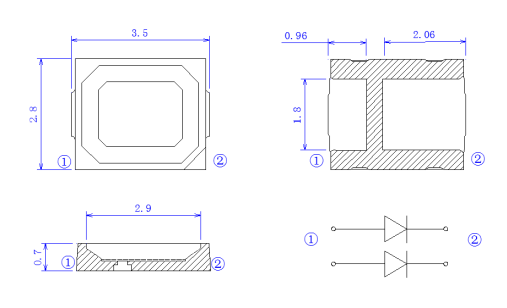

| Size: | 2.8*3.5*0.65mm |

| Packing: | 4000 Pcs/Roll |

Product specification:

Outline Dimension:

Absolute Maximum Ratings:

| Item | Symbol | Maximum | Unit |

| Power dissipation | PD | 1 | W |

| Continuous forward current | IFmax | 60 | mA |

| Peak forward current (1/10 duty cycle 10ms pulse width) | IFP | 80 | mA |

| Reverse voltage | VR | 5 | V |

| Electrostatic Discharge (HBM) | ESD | 2000 | V |

| Operating temperature range | Topr | -40 to +85 | ℃ |

| Storage temperature range | Tstg | -40 to +85 | ℃ |

| Led yunction temperature | Tj | 125 | ℃ |

Electrical/Optical Characteristics:

| Item | Symbol | Condition | Color | Min | Typ | Max | Unit |

Forward voltage |

VF |

IF=60mA | R | 17.5 | 18.5 | 19 | V |

| G | 17.5 | 18.5 | 19 | V | |||

| B | 17.5 | 18.5 | 19 | V | |||

| Viewing Angle | 2θ1/2 | IF=60mA | R/G/B | - | 120 | - | Deg |

Luminous Intensity |

IV | I IF=60mA

| R | - | LM | ||

| G | - | LM | |||||

| B | - | LM | |||||

Wavelength |

WLD | IF=60mA | R | 615 | - | 620 | nm |

| G | 515 | - | 520 | nm | |||

| B | 452 | - | 457.5 | nm | |||

| Reverse Current | Ir | Vr=7V | R/G/B | 0 | 1 | uA | |

| Thermal resistance | Rth(j-s) | IF=60mA | R/G/B | 28 | ℃/W |

Typical Electro-Optical Characteristic Curves:

Reliability Test Items And Conditions:

| No. | Item | Test Conditions | Test hr/cycle/time | Sample Q’ty | Ac∕Re | |

| 1 | Solder Heat | TEMP:260℃±5℃;5±1 sec | 2 times | 30 pcs | 0∕1 | |

| 2 | Solder ability Test ※ | TEMP:235℃±5℃;3±1 sec | 1 time | 5 pcs | 0∕1 | |

| 3 | Temperature Cycle | H:+100℃ 30min. ∫5min. L:-40℃ 30min. | 100 cycles | 20 pcs | 0∕1 | |

| 4 | Thermal Shock | H:+100℃ 5min. ∫ L:-40℃ 5min. | 50 cycles | 20 pcs | 0∕1 | |

| 5 | High Temperature Storage | TEMP:100℃ | 1000 hrs | 20 pcs | 0∕1 | |

| 6 | Low Temperature Storage | TEMP:-40℃ | 1000 hrs | 20 pcs | 0∕1 | |

| 7 | DC Operating Life | IF=IFmax | 1000 hrs | 20 pcs | 0∕1 | |

| 8 | High Temperature High Humidity | 85℃∕85%R.H. | 1000 hrs | 20 pcs | 0∕1 | |

| 9 | Shocking test | 100~2000Hz ;98.1m/s2 X,Y,Z direction | 2 hrs | 20 pcs | 0∕1 | |

| 10 | Dropping test | Put on pallet ;height:75cm | 3 times | 20 pcs | 0∕1 | |

| Judgment Criteria | ||||||

| Forward Voltage VF | VF Max-Increase < 1.1x | |||||

| Reverse Current IR | IR Max-Increase < IRmax | |||||

| Luminous Intensity IV | IV Decay < 40% | |||||

※Solder ability test criteria:coverage is not less than 95% Note:Measurement shall be taken after the tested samples have been returned to normal ambient conditions (generally after two hours) | ||||||

Packing and Shipping Instruction:

Cautions:

The encapsulated material of the LEDs is silicone. Therefore the

LEDs have a soft surface on the

Top of package. The pressure to the top surface will be influence

to the reliability of the LEDs. Precautions Should be taken to

avoid the strong pressure on the encapsulated part. So when use the

picking up nozzle,The pressure on the silicone resin should be

proper.

Soldering iron :

When hand soldering, the temperature of the iron must less than

300℃ for 3 seconds

The hand solder should be done only one times

SMT Reflow Soldering Instructions SMT :

Reflow soldering should not be done more than two times

When soldering , do not put stress on the LEDs during heating

The recommended reflow soldering profile as following

Product features:

Adopt good quality chip and frame ,antistatic good stability Ultra low attenuation

High brightness ,low attenuation high color rendering

Minimum 70,80,90 95 CRI options

Strong welding and good stability undead light

Product series and company logo on the front

CE ROHS LM80 Certification

Production Process: