Jiangsu Lebron Machinery Technology Co., Ltd. |

|

600-305 type K span roof panel roll forming machine

1. Description of 600-305 type K span roof panel roll forming machine

K span roof panel roll forming machine is used for produce K span roof panels.The process is using the forming machine roll bend the color plate to the channel shape, then use the roll machine roll it become to the channel single arc panel. Finally use the locking machine joint it become to a complete plate at one time.

LBM factory is manufacturing high quality K span roof panel roll forming machines, and they are mostly exported to the foreign countries, such as Angola, Congo, Ethiopia, Australia, Turkey, Indonesia, Thailand, Bangladesh, Vietnam, etc.

2. Technical details of 600-305 type K span roof panel roll forming machine

| 1). Size: 8800mmx2200mmx2080mm |

| 2). Total Weight: approx 8 Ton |

| 3). Color: Blue, White, Orange, Custom |

| 4). Suitable Raw Material: PPGI, PPGL, GI, GL Coils |

| 5). Thickness: 0.6mm-1.6mm |

| 6). Suitable Coil Width: below 600mm |

| 7). Yield Strength: 235Mpa-550Mpa |

| 8). Quantity of forming rollers stations: 14 rolls |

| 9). Working speed: Straight sheet: 15m/min |

| 10). Arch sheet speed: 13m/min |

| 11). Sewing speed: 10m/min |

| 12). Max span: 26m |

| 13). Forming rollers material: No.45 steel with chrome coating and heat treatment, HRC 58-62 |

| 14). Cutter material: CR12 mould steel, with quenched treatment |

| 15). Controlling system: PLC+Computer touch screen |

| 16). Forming motor power: 7.5KW |

| 17). Bending motor power: 4.0KW+1.5KW+1.5KW |

| 18). Electric cutting power:3.0KW |

3. Main components of K span roof panel roll forming machine

| Name | Quantity |

| 1). Manual decoiler | 1 Set |

| 2). Guiding device | 1 Set |

| 3). Roll forming Device | 1 Set |

| 4). Hydraulic cutting device | 1 Set |

| 5). Curving device | 1 Set |

| 6). Sewing equipment | 1 Set |

| 7). Support table | 1 Set |

| 8). PLC computer control system | 1 Set |

4. Accessories of 600-305 type k span roof panel roll forming machine

| No. | Name | Amount | Usage |

| 1 | Sewing machine | 2 | Assembling the sheets |

| 2 | Core shaft | 2 | Roll the sheets |

| 3 | Coil cradles | 2 | Sheet roll support |

| 4 | Straight sheet side cradle | 8 | Plate support |

| 5 | Straight sheet cradle | 8 | Plate support |

| 6 | Arch sheet cradle | 8 | Plate support |

| 7 | Driving chains | 3 | To roll the gears |

| 8 | Chain links | 6 | To link the chain |

| 9 | Suspender | 3 | Lifting |

| 10 | Hanger | 8 | Lifting |

| 11 | Clamp | 16 | Bait sheets |

| 12 | Super pliers | 2 | Bait sheets |

| 13 | Mental scissors | 1 | For cutting |

| 14 | Wrench | 1 | For setting screw |

| 15 | Travel switch | 1 | Measure sheet length |

| 16 | Adjust tools | 1 | Adjust machine |

| 17 | Crank | 2 | Adjust legs of machine |

| 18 | VCD | 5 | Teach customer produce |

| 19 | The instructions | 2 | How to use machine |

| 20 | Software | 2 | Help customer calculate engineering |

| 21 | Brochure | 5 | Know my company |

| 22 | The sample single | 5 | Know my comany |

5. K span roof panel roll forming machine work flowchart

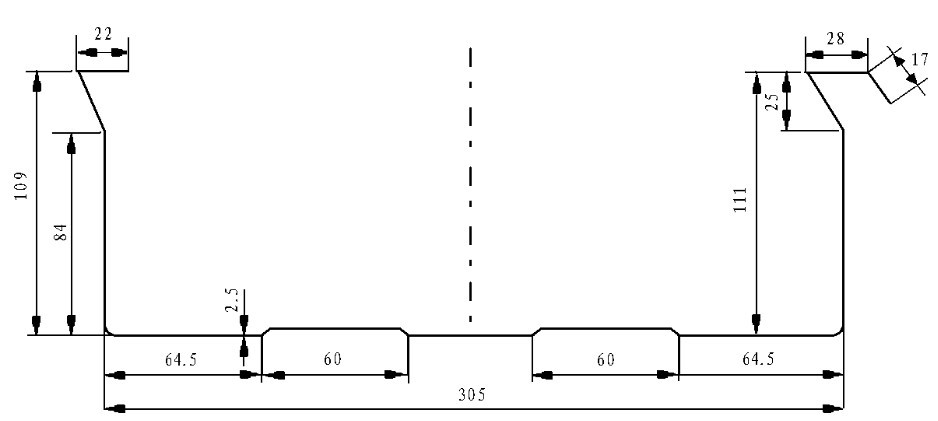

6. 600-305 type K span roof panel sketch

7. Applications of 600-305 type K span roof panel roll forming machine

8. Delivery of 600-305 K span roof panel roll forming machine

9. Our service

Install and Training:

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, manual and video is provided to show how to install and operate.

After-sale Service:

We provide 12-hour online service for our customers. Phone: +86 15821208506

a .The seller will debug the machines freely in China, and the traffic expense in China of the technique people will be paid by the seller.

When technique men go to the buyer's place to debug the machines, the buyer should pay the

expense of accommodation, and round-trip tickets for the seller’s men. and pay the technician USD60 per day.

b. If the buyer sends people to receive the training of the operation given by the seller, during the training period, the seller should pay the expense of accommodation, and traffic for the buyer's men.