RKENS TECHNOLOGY CO.,LTD |

|

This machine include two parts: electric screwdriver and automatic screwfeeder It puts the automatic screwfeeder together with the electric screwdriver in order to achieve the complement of screw transmission and lock, which can greatly improve the production efficiency and save manpower.

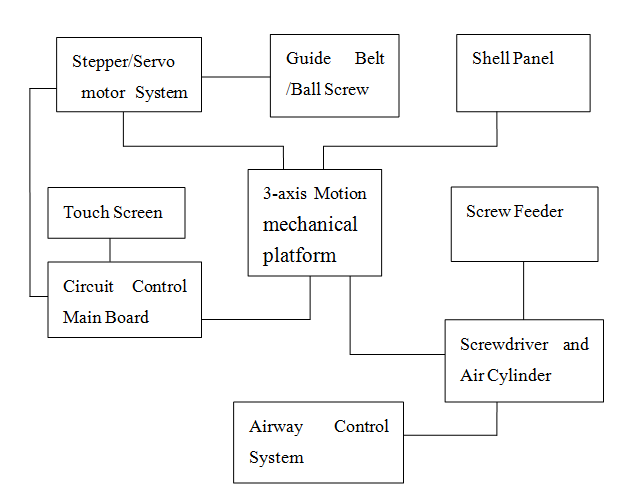

This machine is composed of 4-axis touch screen motion control system, 3-axis mechanical platform, screw feeder, screwdriver, air cylinder, airway control system, machine parts, sheet metal parts, etc.

The screw feeding and tightening machine is used in various operations such as, tightening of screws in various products and various typer of screw.. The screw can be M2-M6 screws, L≥1.2 D (D = screw head diameter, L = length of screw thread) conforms to the condition screw are available this desktop blowing type automatic locking screw machine.

Parameter:

| Model | YS-L301 |

| Route Scale (can be customized) | X:300mm Y:300mm Z:100mm

|

| Move Speed | X:500 mm /sec Y:500 mm /sec Z:800 mm /sec

|

| Voltage | 220V 50Hz |

| Power | 300W |

| Air Source | ≥8Kg |

| Outer Size | W*H*L 550*770*620mm |

| Weight | 70Kg |

| Data Input Mode | Teaching or File Input |

| Human- Computer Interface | 5.7 inch touch screen and special key |

Features:

,Full-automatic screw driver mainly consists of automatic feeding system,X-Y-Z mobile platform,controlling test system and screw screw lock system.

2,The screw driver moves to the set coordinates, the screw system blows screws to bit head, Z axis presses down and lock the screw into products.

3,Screw system automatically feeds another screw while Z axis lifts up,thus complete whole product screw lock process.

4,When replacing different product,only need to change jig and adjust to corresponding working system.

5,Automatic feeding system adopts inductive control to feed automatically, thus avoid screw repetition and block.

Pictures of Desktop Screw Driving And Feeding Robot Machine , Feed And Tighten Screws