Henan Lanphan Industry Co.,Ltd |

|

Verified Suppliers

|

|

Ethanol Distillation Thin Layer Falling Film Evaporator 20L/H

Product Parameter

| product model | FFE-20 | FFE-50 | FFE-100 | FFE-200 | FFE-500 | FFE-1000 |

| evaporation rate(L/H) | 20 | 50 | 100 | 200 | 500 | 1000 |

| heating area(㎡) | 1.2 | 3 | 5 | 12 | 25 | 50 |

| cooling area(㎡) | 1.5 | 5 | 7.5 | 16 | 30 | 60 |

| charge pump(kw) | 0.55 | 0.55 | 1.1 | 1.5 | 1.5 | 1.5 |

| discharge pump(concentrate,kw) | 0.55 | 0.55 | 1.1 | 1.5 | 1.5 | 1.5 |

| discharge pump(ethanol,kw) | 0.55 | 0.55 | 1.1 | 1.1 | 1.5 | 1.5 |

| circulating water vacuum pump(kw) | 0.75 | 0.81 | 0.81 | 1.5 | 2.2 | 3.85 |

| total power(kw) | 2.4 | 2.46 | 4.11 | 5.6 | 6.7 | 8.35 |

| voltage | 220V/60Hz | |||||

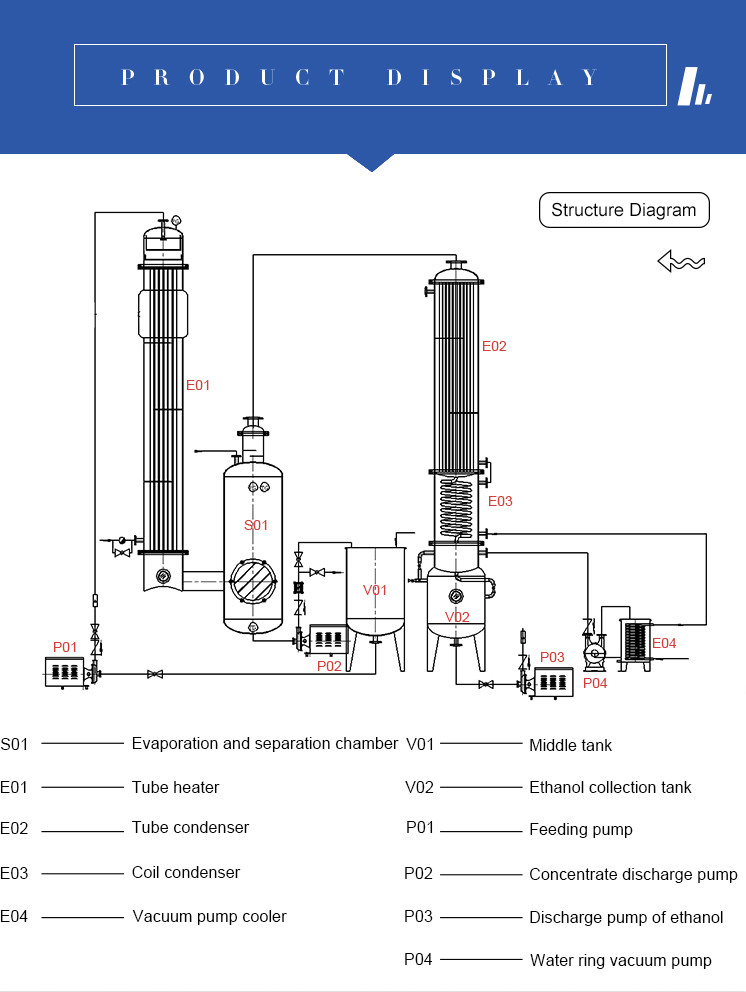

product description

The function of the monoethanol falling film evaporator is to

separate the ethanol from the feed liquid and condense and recover

the extract after the decompression vacuum evaporation. In the

condenser, the boiling point of ethanol is lowered and it is easy

to evaporate. Evaporation is easy to carry out, especially under

vacuum and reduced pressure. Therefore, the evaporation area is

reduced, and the condensation and recovery of alcohol vapor is

difficult, so the heat exchange area of the condenser is increased.

In order to obtain a good cooling effect, two-stage or multi-stage

cooling and recovery are often used, which is also different from

general aqueous solution evaporation.

Principle of Falling Film Evaporation

The material liquid is evenly distributed into each falling film tube through the distributor, and flows down the pipe wall in a liquid film state. Under the action of gravity and secondary steam flow, the material liquid flows down while evaporating, and reaches the falling film. At the lower end of the pipe, the material liquid and the secondary steam are basically separated and reach the separation chamber to achieve complete separation.

Product advantages

Low evaporation temperature;

Fast evaporation rate;

The material liquid residence time is short;

It can realize continuous feeding and continuous discharging;

Suitable for heat-sensitive materials;

Low energy consumption.

Application scope

Single-effect falling film evaporators are widely used in food,

dairy, chemical, pharmaceutical, bioengineering, environmental

protection engineering and corn deep processing, such as water

solution, organic solvent solution, fruit and vegetable juice,

milk, eggs, vitamin C, collagen , The evaporation and concentration

of tea infusion, sodium glutamate, etc. is especially suitable for

the evaporation and concentration of heat-sensitive materials. The

beneficial elements of the materials can be protected to the

greatest extent during the heating and evaporation process.