Hai Da Labtester |

|

Verified Suppliers

|

|

Stroller Crash Test & Side Stability Test Platform Lab Test Machines

Application:

Every day children are hurt when interacting with products in their daily environments, even with products made especially for children, such as the baby strollers, baby carrie, baby toys, baby bed etc…

HD-J201 Stroller Crash Test & Side Stability Test Platform is designed based on EN 1888 Cluase 8.10.3 requirments, which can help the manufacturer and the testing orginzation to finished the Crash Test & Stability Test.

Testing method is pram placed on the sandpaper of surface of the machine, adjust the tilt angle of the test bench, and then view the pram slip or not during at least 30 seconds.

Standard Features:

| Surface of testing table | Sandpaper 60# *1pcs Sandpaper 80# *1pcs Sandpaper 120# *1pcs |

| Table Size | 1300*2200mm |

| Mode of angle adjustment | Electric Adjust |

| Angle display | LCD display |

| Angle accuracy | 0.5° |

| Angle adjusted | 0° up to 30° |

| Standard | EN 1888 claus8.9 |

| Control method | PLC control |

| EN 1888 clause 8.9 requirements as below | |

| Rectangular block | 25mm |

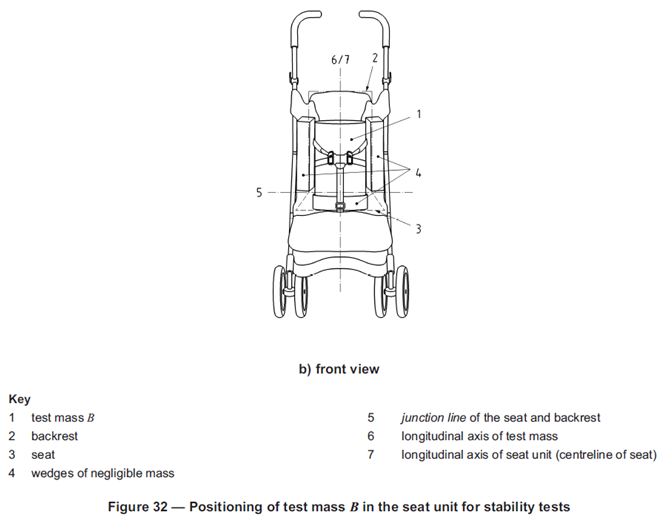

| Test Mass | Type A &B |

Stability Test Side View

Arrangement for the irregular surface test

The guarantee period with FOC within 1 year (not including expendable parts cost and transport & travel fees)

1.1 During the guarantee period, Haida shall supply free maintenance or replacement for the damaged part (just for non-expendable part) caused by non-human reasons;

1.2 If any quality problems occur within the guarantee period, and Haida must provide on-site service, the transport and travel expense shall be borne by buyer;

1.3 If any big quality problems occurs out of the guarantee period, Haida will provide a maintain service, the transport and travel expense shall be borne by buyer, also charge for a favorable price for new parts;

1.4 Haida will provide a lifetime favorable price to the buyer for expendable & non-expendable parts used in system operation, equipment maintenance;