Changsha Tianchuang Powder Technology Co., Ltd |

|

Verified Suppliers

|

|

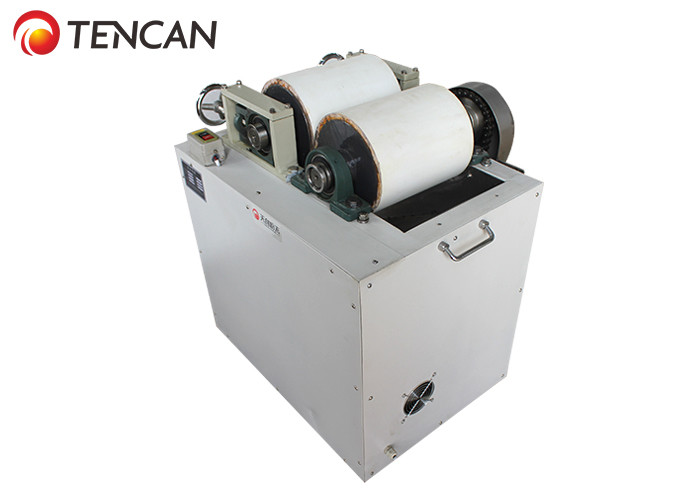

TENCAN Double Roll crusher with Stainless steel roller capacity 300kg per hour

Overview

Alumina ceramic double roll crusher is also named double-roll crusher,roll-type crusher.It is usually used to crush the raw materials such as coal , coal gangue, coke , limestone, sulfur ore, phosphate rock and etc, which are usually crushed in middle or fine size by the way of roll extrusion .Roll crusher is widely used in the fields of ore dressing, chemical, cement, refractories, grinding materials, building materials, etc., and it has more excellent performance than the general machinery in crushing of building materials, particularly in crushing materials like gangue stone and mung bean stone.

Working Principle

1. Roll crusher mainly consists of rollers, roller support

bearings, pressed and regulation devices, drives, and etc.

2. Adjusting of output granularity: there is a wedge or gasket

adjusting device between the two rollers. Wedge adjusting

device:there is a adjusting bolt on the top of the Wedge device.

When the wedge is pulled up by adjusting bolt, the wedge pushes the

movable roller away from the fixed roller. That is to say, when the

gap of the two rollers becomes wide, output granularity shall

become larger accordingly. When the wedge falls down, the gap of

the two rollers becomes small under pressure of the spring, output

granularity becomes small. Gasket adjusting devices: it is used to

adjust output granularity by means of increasing or decreasing

numbers or thickness of the gasket. When adding gaskets, the gap of

the two rollers becomes wide,and output granularity becomes large,

when decreasing gasket, gap of the two rollers becomes small, and

output shall be fine accordingly.

3. There are two motors which drive the rollers by V-belt. Both

rollers rotate in opposite direction.

4. When materials are being crushed, the feed material are in put

from the inlet and crushed by the rollers, and finally the crushed

products are out put from the chassis below .

5. For security, transmission security cover should be installed

according to the actual situation.

Applications

Double-roll Crusher Machine is mainly applied to crushing all kinds of materials, which are less than comprehensive strength limit of 2000kgs per square centimeter, such as ore, limestone, coal gangue, slag, carbon block in the industry of refractory material, chemical, coal, building material and so on.

Features

1. Long service life, no easy to damage

2. Compact structure,light weight and small size

3. Simple structure, small footprint, easy to operation and

maintenance

4. Reasonable structure low running cost, smooth operation,

energy-efficient, high crushing efficiency

5. Dust board installed inside,good sealing performance, avoid

splashing of crushed fine material

6. The particle size is adjustable, after tune of the roll gap, the

broken particle size can be reliably controlled accordingly, and

all the granularity will be discharge in the ideal size.

Parameters

| Parameter of Double-roll Crusher | |||

| Material of roller | Stainless steel | Corundum (alumina ceramic) | Nylon |

| Roller size(mm) | Φ200*240mm | Φ200*240mm | Φ200*240mm |

| Rotation speed(r/min) | 52 | 52 | 52 |

| Feed Size | ≤10mm | ≤10mm | ≤10mm |

| Output Granualrity (μm) | >150um | >150um | >150um |

| Power supply (V) | 380 | 380 | 380 |

| Capacity(kg/h) | 300 | 300 | 300 |

| Motor power(kw) | 1.5 | 1.5 | 1.5 |

| Dimensions(mm) | 950*620*970 | 950*620*970 | 950*620*970 |

| Net Weight | 220KGS | 240KGS | 220KGS |