Anping Yuanqiao Petrochemical Equipment Co., Ltd |

|

Verified Suppliers

|

|

| Product: | Trough Liquid Distributor | Flow Rate: | As Per Requirement |

|---|---|---|---|

| Material: | Stainless Steel | Type: | Gravity Type Trough Type |

| Plate Thickness: | 3 Mm, 4 Mm, 5 Mm, 6 Mm, Etc. | Size: | Any Size As Per Order |

| Position: | On Top Of Packing | Application: | Packing Tower |

| Design Service: | OEM | Advantage: | Uniform Distribution |

| High Light: | random packing distributor liquid,tower internals distributor liquid,custom flow rate liquid controls distributors | ||

Column Diametermm | Specific liquid loadM3/m2*h | System fouling tendency | Turndown ratio | Suitable type of liquid distributor |

250 - 900 | 0.75 - 5 | Low - medium | <10:1 | Trough type liquid distributor with sumpDeck type liquid distributor with orifices on drip tubes |

5 - 30 | Low - medium | 2:1 | Pan type liquid distributorTrough type liquid distributor with sump | |

>30 | Low - medium | 2:1 | Pan type liquid distributorTrough type liquid distributor with sumpDeck type liquid distributor | |

>900 | 0.75 - 5 | Low - medium | <10:1 | Trough type liquid distributor with parting boxDeck type liquid distributor with orifices on drip tubes |

5 - 30 | Low - medium | 2:1 | Trough type liquid distributor with sumpTrough type liquid distributor with parting boxDeck type liquid distributor | |

>30 | Low - medium | 2:1 | Deck type liquid distributorTrough type liquid distributor with sump |

1.Make the liquid distributor from multipoint into infinite point.

The distribution uniformity has an impressive promotion. Make the

line distribution and surface diatribution come true.

2. Eakage blocking design.

3. Simple construction, Lower placeholder, Light weight, Easy

installation.

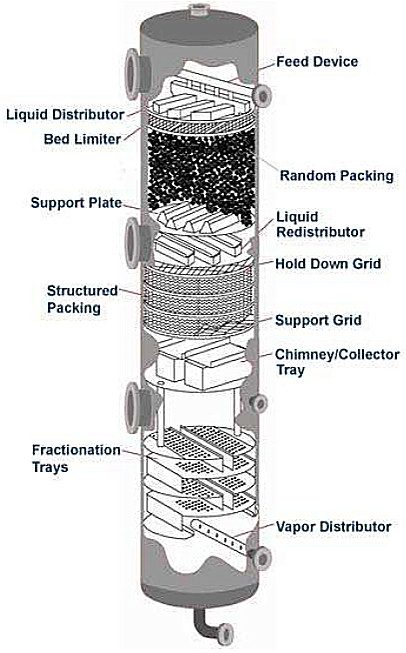

Welcome your inquiryStructured Packing specifications.

The liquid distributor has various types according to different

standard and using conditions. Overall, it has four types.

* Spray nozzles. Hemispherical spray nozzle will distribute the

liquids evenly to the random or structured packing bed. There are

numerous small holes in 3–10 mm on the nozzle. It is suitable for

the smaller diameter packed tower, which is smaller than 600mm.