Kelite Valve(Shanghai) Co., Ltd |

|

2"-36" CL150-1500 bolted bonnet swing cast check valve, RF, OS&Y design

| Size: | NPS 2"~36" |

| Pressure Rating: | Class 150~2500 |

| Material: | WCB, LCB,WC6, WC9, C12, C5,CF8, CF8M, CF3, CF3M |

| Design & Manufacturing Standard: | API 600, BS 1868, ASME B16.34 |

| Face to Face: | ASME B16.10, API 6D BSEN558 |

| End Connection: | ASME B16.5, ASME B16.47, ASME B1.20.1 , ASME B16.11,DIN 2453-2551, ASME B16.25 |

| Test and Inspection: | ISO 5208, API600,BS 6755 |

| Operation Method: | Swing type, lifting type |

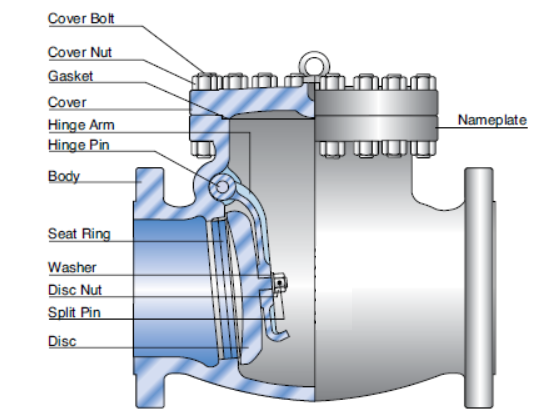

Design

Kelite cast steel check valves are designed and manufactured to provide maximum service life and dependability. All check valves meet the design requirements of American Petroleum Institute standard API600 & 6D.BS EN 13709 and generally conform to American Society of Mechanical Engineers standard ASME B16.34. Valves are available in a complete range of body/cover materials and trims.

Ranges of Materials

Standard body/cover materials include nine grades of carbon, low alloy and stainless steels, for special applications they can be supplied in other grades of alloy and stainless steel, there’s a full range of trim materials to match any service optional packing and gasket materials are available for a full range of service conditions.

APPLICATION & FUNCTION

Swing check valves are designed to close quickly and automatically with positive shut off in either horizontal or vertical (flow up) pipe runs. Inherently, swing check valves have a low pressure drop and are best suitable for velocity applications. Our closure design allows our swing check valve to close completely even and remain closed with no flow when installed in a horizontal pipe run.

BODY

The body is full ported and spherical in form.The design utilizes

large radiuses which allow for the stresses, flow resistance and

turbulence to be kept to a minimum. Bosses are provided for

optional drains.

HINGE ASSEMBLY

The hinge arm pivots on the hinge pin which is located near the

disc’s center of gravity. Body penetration for the hinge pin is

sealed with a soft steel gasket and flanged plug. The hinge arm is

designed to withstand the shock load of quick closing to insure a

longer life and continued shut-off. The hinge arm also has an

integral disc stop that provides a positive stop in the open

position.

DISC

Each disc’s seating surface is precision ground and mated to the

seat ring for insurance of a positive shut off. The disc is secured

to the hinge arm with the disc nut and pinned to prevent

disengagement during service. We can provide either integral or

overlaid seat facings at customer’s request.

SEAT RING

Seat rings are designed to greatly reduce and/or prevent any

turbulence and avoid damages due to corrosion. The seat rings are

forged or rolled in one piece and then seal welded and overlaid, if

required. After welding and all required heat treating, the seat

ring faces are machined, thoroughly cleaned and inspected before

leaving for assembly.

BOLTS AND NUTS

For normal service conditions, ASTM A194 Class 2H and ASTM A193

Grade B7 nuts and stud bolts are furnished. If specified for high

temperature service conditions, ASTM A194 Class 4 and ASTM A193

Grade B16 nuts and stud bolts are furnished. Standard bolting

furnished for our stainless steel valves consists of ASTM A194

Class 8 and ASTM A193 Grade B8 nuts and stud bolts.

END CONNECTIONS

Our standard production covers valves with:

ACCESSORIES/OPTIONAL DESIGNS

Counterweight features are available as an accessory. Piston,

tilting disc or API- 6D designs are also available to meet the

customers requirements. Drains and bypasses are available as

specified by the customer.

Applicable Standards:

● STEEL CHECK VALVES, API 6D

● STEEL CHECK VALVES,ISO14313

● STEEL VALVES,ASME B16.34

● FACE TO FACE, ASME B16.10

● END FLANGES,ASME B16.5

● BUTTWELDING ENDS,ASME B16.25

● INSPECTION AND TEST, API 598/API 6D

Design descriptions:

● BC,BOLTED COVER

● WING TYPE,ANTI-ROTATION DISC

● RENEWABLE SEAT RINGS

● NON-PENETRATE DISC SHAFT

● HORIZONTAL OR VERTICAL SERVICE

● FLANGED OR BUTTWELDING ENDS