Zhejiang Canaan Kaixinlong Technology Co., Ltd. |

|

Verified Suppliers

|

|

Overview of the machine:

Automatic Capsule Filling Machine CFK-1500C Introduction Of Product Capsule Filling Capsule

Technical parameters:

| Output | 1500Capsules/min |

| No.of segment bores | 11 |

| Suitable fof capsule | 00#-5# |

| Total power | 8Kw(Standard configuration) |

| Overall weight | 1400Kgs |

| Overall diemensions | 1230mm×1175(+382)mm×1955mm |

| Noise | ≤75DB(A) |

| Pressure | 0.4 ~ 0.7Mpa |

| Air consumption | ≤6m³ |

| Vacuum | -0.03 ~ -0.06Mpa |

| Filling error | ±2.5%~±5% |

The machine may make technical improvements without prior notice, and the attached picture shows the options that may be offered.

The process of capsule filling:

The smooth drive system:

|  |  |

| Indexing box | Transmission part | Inside groove cam |

Closed station turntable:

1.Use the imported silicone sealing ring to reduce the condition

that the powder is brought into the turntable due to the expansion

of the movement axis, and smooth operation, high accuracy;

2.It solves the complicated problem of installing and dismantling

the mold, reduces the labor intensity of the staff, and strengthens

the service life of the station rotary table.

Three-dimensional adjustment mechanism:

Easy to remove the hopper:

| The old hopper, loosen the hand wheel on the supporting column when disassembly and cleaning, and stretch on the long pressure spring in the column. Most of the hopper must be extended out of the upper Plexiglass to be removed. During the installation, the pressure spring needs to be squeezed to the bottom before tightening the hand wheel, and the employees need to spend a lot of effort to operate. |

| A screw was added to the supporting post, the screw passed through the panel, the top connecting the hopper support, and the motor and turbine box were installed at the bottom. During hopper disassembly and installation, the whole lifting process can be operated on the PLC operation panel. Due to the use of a single screw support, the work when there is a slight shaking phenomenon. |

| The split structure is directly fixed on the lower plane of the roof, with simple structure, stable and reliable when working, and convenient hopper disassembly. Release the fast interface of the material cylinder, then loosen the four screws on the hopper, then rotate out the small pin on the paddle, you can horizontally pan out of the filling part. |

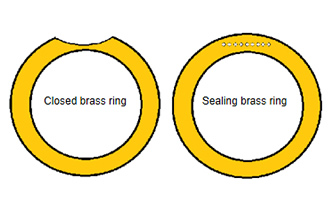

Copper collar:

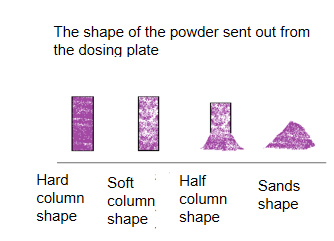

| 1.Hard column: stable particle weight, loading amount close to the

maximum value, one or two groups of filling rods have obvious

beating, the adjustment range is too small, the machine load is

large, the corresponding parts wear fast. 2.Soft column: stable grain weight, large adjustment range, small

load, small wear of parts. Half column: sometimes appear puff powder particle weight and

light. 3.Scattered sand: leakage, dirty machine table, installation

difference. The gap type copper ring can be replaced with the

sealing type. |

| According to the material situation, the company provides the optional replacement copper ring |

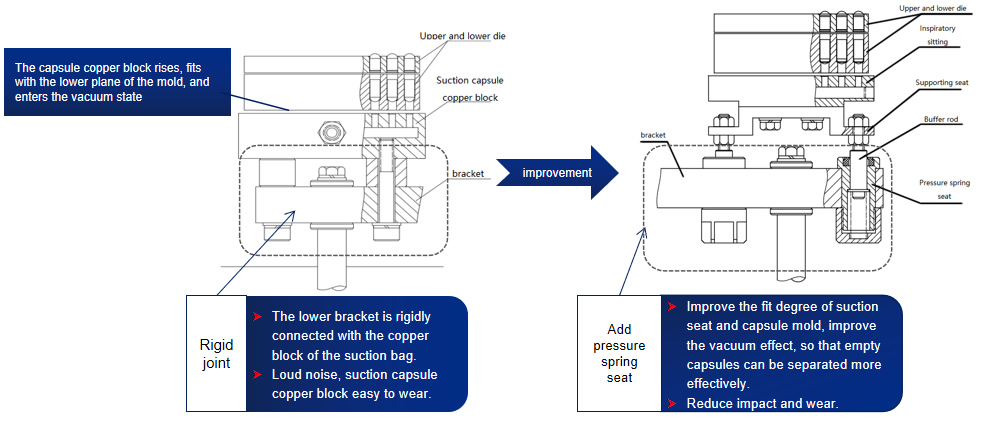

Vacuum separation mechanism:

Modular powder filling mechanism:

Other performance: