Zhejiang Canaan Kaixinlong Technology Co., Ltd. |

|

Verified Suppliers

|

|

Overview of the machine:

Automatic Capsule Filling Machine NJP-400C Introduction Of Product Powder Capsule Filling Machine

Technical parameters:

| Output | 400Capsules/min |

| No.of segment bores36 | 3 |

| Suitable fof capsule | 00#-5# |

| Total power | 4Kw(Standard configuration) |

| Overall weight90 | 900Kgs |

| Overall diemensions | 760(+304)mm*780mm(+304)*1900mm |

| Noise | ≤75DB(A) |

| Pressure | 0.4 ~ 0.7Mpa |

| Air consumption | ≤6m³ |

| Vacuum | -0.03 ~ -0.06Mpa |

| Filling error | ±2.5%~±5% |

The machine may make technical improvements without prior notice, and the attached picture shows the options that may be offered.

The process of capsule filling:

Closed station turntable:

1.Use the imported silicone sealing ring to reduce the condition

that the powder is brought into the turntable due to the expansion

of the movement axis, and smooth operation, high accuracy;

2.It solves the complicated problem of installing and dismantling

the mold, reduces the labor intensity of the staff, and strengthens

the service life of the station rotary table.

Three-dimensional adjustment mechanism:

Copper collar:

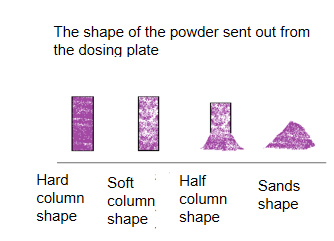

| 1.Hard column: stable particle weight, loading amount close to the

maximum value, one or two groups of filling rods have obvious

beating, the adjustment range is too small, the machine load is

large, the corresponding parts wear fast. 2.Soft column: stable grain weight, large adjustment range, small

load, small wear of parts. Half column: sometimes appear puff powder particle weight and

light. 3.Scattered sand: leakage, dirty machine table, installation

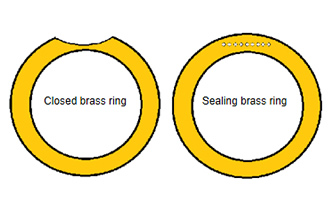

difference. The gap type copper ring can be replaced with the

sealing type. |

| According to the material situation, the company provides the optional replacement copper ring |

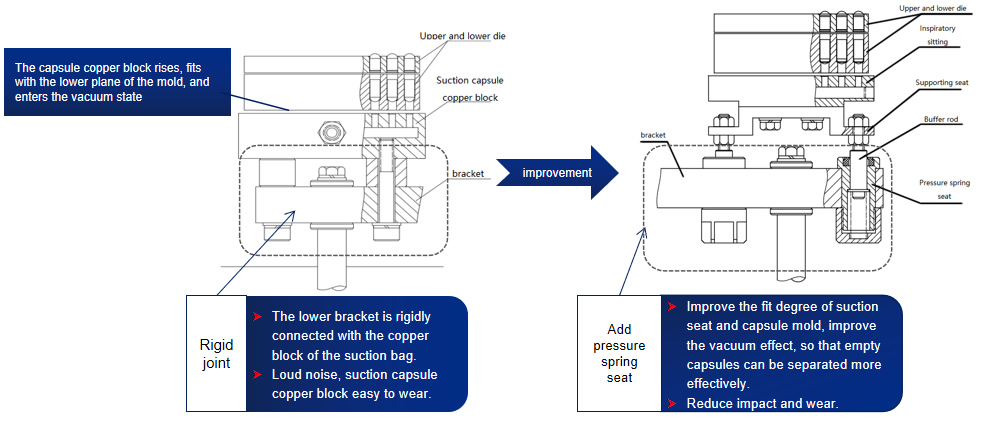

Vacuum separation mechanism:

Modular powder filling mechanism:

Other performance: