Jiangsu Jinwang Intelligent Sci-Tech Co., Ltd |

|

Verified Suppliers

|

|

Main application areas Packaging Stacking-up Stacking down Material material up and downMultifunctional industrial robot

IRB 460.

Multifunctional industrial robot

Main application areas

Packaging

Stacking-up

Stacking down

Material material up and down

Machine tool management

Reduce the beat time

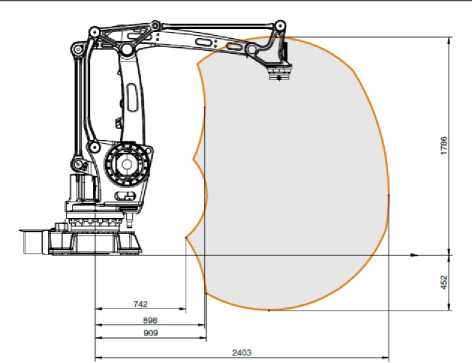

IRB 460 is the world's fastest four-axis multi-function industrial robot, which can significantly shorten the beat time of various operations and greatly improve the production efficiency. The compact 4-axis robot reaches a distance of 2.4 m, effective charge 110 kg; charge 60 kg beats up to 2,190 cycles / hour (400mm x 2000mm x 400mm), 15% faster than competing products under similar conditions.

High-precision operation

With ABB patented QuickMove ™ and TrueMove ™, IRB 460 has smooth movement and excellent path accuracy, and can carefully "care" even for the most sensitive products, while ensuring that the beat time is not affected.

Small land footprint and high output

With a compact design of IRB 460 and the pallet, the distance between it can be 20% shorter compared to similar products with speed and load proximity, and this item alone can improve production efficiency by up to 3%.

Low cost of ownership and high productivity

IRB 460 is manufactured in the automotive industry, with a stable structure, reliable design, long normal operating time and low maintenance cost.The robot is equipped with integrated process cables to reduce wear and extend its service life. ABB also provides RoboGare three-year warranty plan to ensure carefree production without additional costs. The plan includes ABB patented wireless remote services. ABB experts monitor the robot status and provide corresponding optimization maintenance recommendations to improve production efficiency,

Programming is faster and simpler

Humanized software Robotstudio Palletizing PowerPac with ordinary PC machine as the running platform, enabling users without robot programming experience to also conduct programming and simulation operations. The software follows the concept of "substitute programming with configuration" and saving up to 80% of programming time.

Unsurpassed professional experience and global support

ABB is a multinational enterprise with nearly 30 years of experience in robotics, with more than 100 sales and service sectors in 53 countries and regions.

| Stacking, stacking, material handling | ||

| Specification | ||

| Load load | 110 kg. | |

| Distance rival distance | 2.40 m. | |

| Number of axafts | 4 | |

| Protection level | IP67. | |

| Install it | Floor | |

| IRC5 controller model | Single cabinet | |

| Integrated electrical signal source | Optional option | |

| Integrated air source | Optional option | |

| Physical properties | ||

| Robot base size | 1007 x 720 mm. | |

| Robot weight | 925 kg. | |

| Performance " measured according to ISO 9283 standard) | ||

| Repeat location accuracy (RP) | 0,20 mm. | |

| Duplicate loop accuracy (RT) | 0.11 mm. | |

| Exercise | ||

| Axis movement | Scope of work | Maximum speed |

| Axis 1 | +165.〜-165. | 145 ° / s. |

| Axis 2 | +85° 〜-40° | 110 ° / s. |

| Axis 3 | +120° ~-20° | 120 ° / s. |

| Axis 4 * | +300° ~ -300° | 400 ° / s. |

| * + 150 rev —150 rev (max) | ||

| Supply voltage | 200 — 600 V,50 〜60 Hz. |

| Power consumption | ISO cube 3.67 kW. |

| Environment | |

| Mechanical part of the ambient temperature' | |

| When operation | + -0 °C (32 °F) to + 45 ° C (113 ° F) |

| During transportation and storage | -25 ° C (-13 °F) to + 55 ° C (131 ° F) |

In a short time (Not exceeding 24 hours) | Up to + 70 ° C (158 ° F) |

| Relative humidity | Up to 95% |

| Noise level | <70 dB (A) |

| Safety | Dual circuits with monitoring, emergency stop, and safety functions, A 3-bit starter device |

| Radiation | EMC/EMI shielding |