Jiangsu Jinwang Intelligent Sci-Tech Co., Ltd |

|

Verified Suppliers

|

|

DXD-180F-type fully automatic horizontal bag machine

General information:

The DXD-180F-type automatic horizontal bag machine includes motor release, bag forming, bag bottom seal, vertical seal, servo holding, shear, unpacking inspection, bag filling, bag transfer, bag dust removal, bag top sealing, through each cam on the motor drive spindle, and the encoder on the spindle feedback position signal, under the programmable control of PLC, realizes the function of → bag inspection by → bag, and finally manually box or box. The machine has reasonable design, novel appearance, using standard stripe seal, replacement filler can realize powder, particles, suspension, emulsion, water and other materials automatic filling. The whole machine is made of SUS304 stainless steel and has good corrosion effect on highly corrosive materials. Plexiglass outer cover, to prevent dust leakage, more environmental protection and pollution-free.

(The main device without the device is optional)

Technical parameters:

| 1 | Production capacity | 40-60 bags / points (Single bag); (40-60) × 2=80-120 bags / points (Double pack) * Actual capacity depends on the packaging material and package size |

| 2 | Suitable for the bag type | Single bag, double coupling bag |

3 |

Package dimensions | Single bag: 70 × 100mm(minimum); 180 × 220mm(max) Double linked bag: (70 + 70) × 100mm(minimum) (90 + 90) × 160mm(max.) |

| 4 | Packaging capacity | General: ≤ 100ml(single bag); ≤ 50 × 2=100 ml(double coupling bag) * Actual packing quantity depends on the material specific gravity and packing size and the optional packing device |

| 5 | Fill accuracy | ± 1% * Actual accuracy is determined by the material stability and the optional filling device |

| 6 | Refilm size | Inner diameter: Φ70-80mm Outer diameter: ≤ Φ500mm |

| 7 | Dust removal pipe diameter | Φ59mm. |

| 8 | Power Supply / Power | Three-phase AC380V 50Hz/6KW |

| 9 | Gas consumption | 840L/ points |

| 10 | Equipment dimensions | 4175 × 1045 × 1590mm (L × W × H) |

| 11 | Complete machine weight | About 2,000 Kg |

Equipment dimension drawing:

Equipment advantages:

1.1 Bag opening detection: automatic detection function, mechanical bag opening device, to ensure 100% bag opening. If the bag is not open or open the bag is not complete, do not add the material is not hot seal, do not waste the materials to save the production cost for users.(This feature is optional)

1.2. Bag mouth dust removal device: bag dust removal function, motor drive cleaning dust, to ensure the success rate of sealing.(This feature is optional)

1.3Unique double scissors device: the automatic horizontal bag machine adopts the form of double scissors, to improve the production capacity, and double the original production capacity on the basis of single bag filling. (This feature is optional)

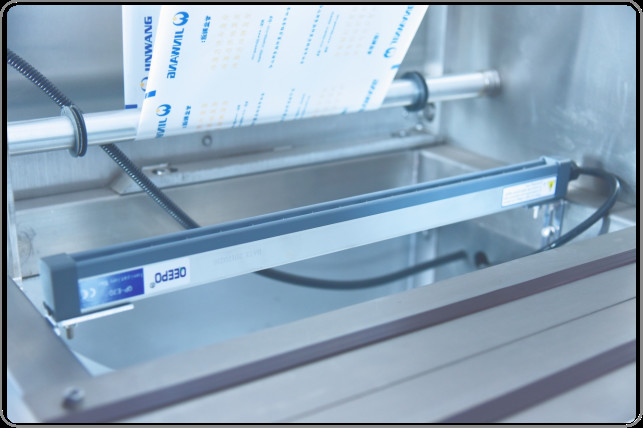

1.4Electrostatic removal rod to eliminate static electricity at the film to ensure that the bag is more stable. (This feature is optional)

1.5Servo bag system: specification replacement, one key input, less packaging loss.(This function is optional)

1.6In order to prevent adhesive, bag, adhesive of hot parts on the equipment after a long use, special spraying on the surface of bottom seal, vertical seal, middle seal and top sealing shall be applied to avoid the above situation

1.7Weighing feedback system: measurement adjustment tentacles to reduce material waste (this function is optional).

1.8General of the filling device: the powder, water, viscosity, particles and other filling devices are reserved on the software. Users only install the plug-in, and the function can be called in the touch screen

1.9Central operation control: the central control box is installed in the middle of the equipment, beautiful, easy and convenient for operation and maintenance. Workers do not need to run back and forth in the operation, which can effectively improve the work efficiency. Equipped with independent operation button box, with dose fine adjustment, pilot adjustment and other functions, more convenient operation.

1.10Automatic grease injection machine: use Pulsarlube-M automatic grease injection machine imported from the United States to avoid the trouble of delayed manual maintenance cycle and prolong the service life of the organization. (This function is optional)

2, is more suitable for the overall structure of agrochemical production

2.1 Jinwang packaging is rooted in the agrochemical more than ten years of experience in the industry, the whole machine uses SUS304 stainless steel processing, with excellent corrosion resistance; organic glass cover, to prevent dust leakage, more environmental protection and no pollution.

2.2 All connecting parts of the machine are SUS304 stainless steel casting, strong without deformation. Other manufacturers generally use welding connecting rods, which are easy to break and easy to deform.

2.3 Jinwang packaging is rooted in more than ten years of experience in the packaging industry. SUS304 stainless steel has excellent corrosion resistance; automatic horizontal equipment and overall arc environmental protection framework protection during operation.

3, membrane replacement bag device

When the film is exhausted, there is no need to pull out the remaining film on the device, but only to glue it to the new film to reduce the packaging loss. (This feature is optional)

An independent tear mechanism is adopted, and the cylinder drives the cutter to reciprocate the movement to achieve the tear effect, which is easy to tear and beautiful. The use effect is far beyond the hot block tear, and a debris collection device is set on the tear device. Pipe collection chip bucket with diamond ripping is convenient and quick (this function is optional)

Main configuration of the equipment:

| No ial | First name "Said that." | Product Card |

1 | Programmable controller CPU. | Schneider. Schneider |

| 2 | Touch-screen | Schneider. Schneider |

| 3 | Converconverter | Schneider. Schneider |

4 |

Servo system | Schneider. Schneider |

| 5 | Approach sensor | Sick. Schker |

| 6 | Color sor detector | SUNX. Japanese vision |

| 7 | Switch on the power supply | Schneider. Schneider |

| 8 | Vacuum generator | SMC. |

| 9 | Heat fan | SUNON. Completion permit |

| 10 | Encoder | OMRON. The Omron |

| 11 | Button | Schneider. Schneider |

| 12 | Circuit breaker | Schneider. Schneider |